Canadian plasma specialist PyroGenesis (OTCQB: PYRNF) has announced a new 3D printer materials division under the name PyroGenesis Additive. First proposed in 2016, the launch has been timed strategically after assessing the market, and receiving significant interest in the company’s specific method of metal powder production.

From the inventors of the plasma atomization process

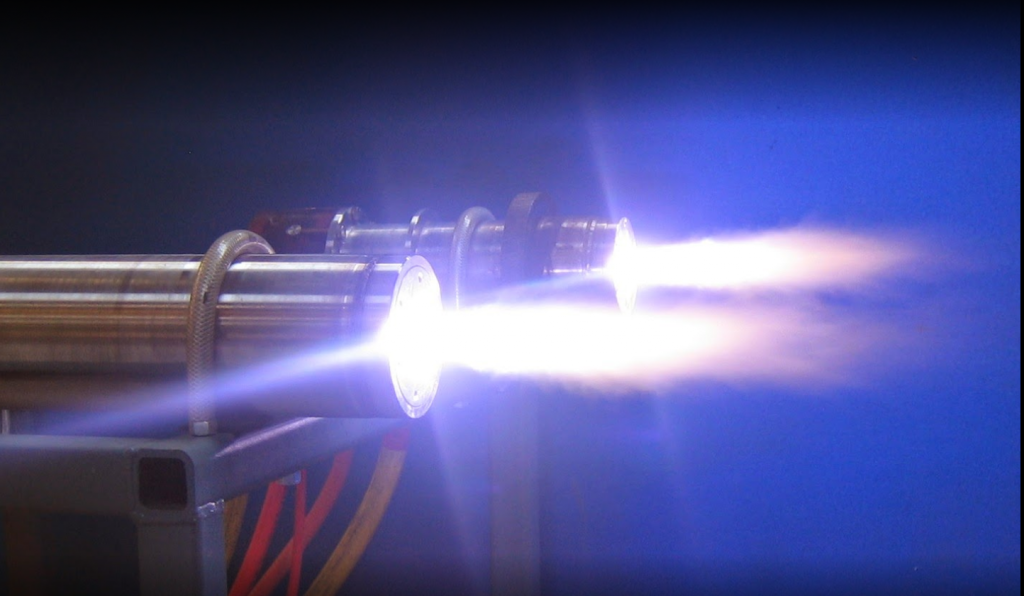

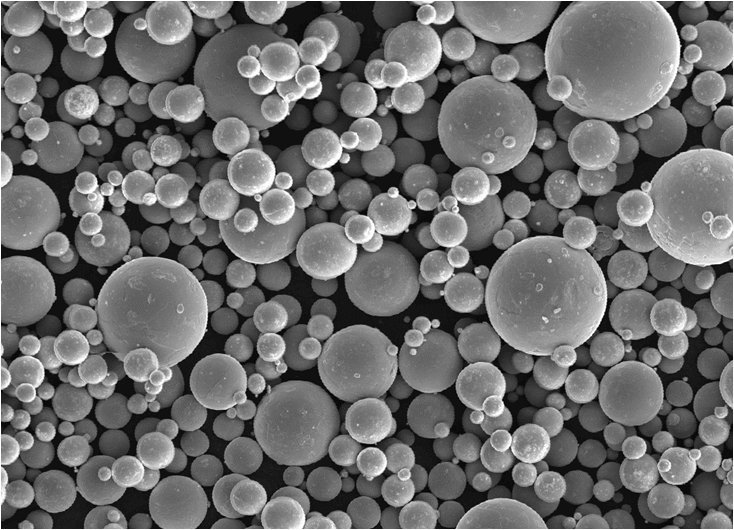

PyroGenesis’ materials for metal additive manufacturing are produced using the company’s proprietary plasma atomization process, patented in 2015. The process works by firing a metal alloy through heated jets of plasma (energized gas molecules) which turns it into spherical particles.

Powders produced in this way are suited to metal powder bed fusion techniques of 3D printing, i.e. direct metal laser sintering/selective laser melting and electron beam melting.

The competition

Up until 2012, materials producer AP&C, acquired by GE as part of its $1.4 billion takeover of Arcam and Concept Laser, was in an agreement with PyroGenesis allowing both companies to use the same plasma process. Addressing this competition, P. Peter Pascali, President and CEO of PyroGenesis, says,

GE’s acquisition of Arcam, and by extension of AP&C, has effectively disrupted the supply chain of speciality powders in the AM Industry which has caused end users of such powders to re-examine their access to them, all while PyroGenesis is re-entering the market as a supplier of such powders.

This, in part, is why the company have waited until now to launch the additive branch. Pascali also stipulates that,

We have definitely underestimated the interest in our production and it has become apparent that we need to expand our capacity faster than originally planned. We currently have plans to order the long lead items for 3 more systems in anticipation of having to address this need.

Progress faster than expected

PyroGenesis’ first successful powder run was completed March 2017. Since then, the company have received a second order for titanium alloy powder from a client based in the United States. Pascali also intimates that the company has applied the plasma atomization process to aerospace-grade superalloy Inconel, as used in research for NASA and a collaboration between SPbPU and TU Delft.

Adapting the process for the new material, Pascali comments,

…the powder production rate was far greater than that for Titanium and the Inconel powder was of exceptional quality; proving, amongst other things, the flexibility of our Plasma Atomization System and how quickly we can “pivot”.

“Making great strides”

In line with the launch, the company has also announced the expansion of its ISO 9001:2008 quality control certification to incorporate more additive manufacturing specific protocols.

Closing the announcement, Pascali states,

…our goal is not only to become a significant producer of metal powders to the AM Industry, but to bring the technology to a new level and enable 3D printing to reach new heights by effectively making our old technology, the gold standard, obsolete. We are making great strides on both fronts, and we have only been up and running for less than 3 months.

For the latest 3D printing news sign up to our free newsletter, like us on Facebook and follow us on Twitter.

Featured image Inside the crucible of PyroGenesis’ plasma atomization process for metal powders. Photo via PyroGenesis on Twitter