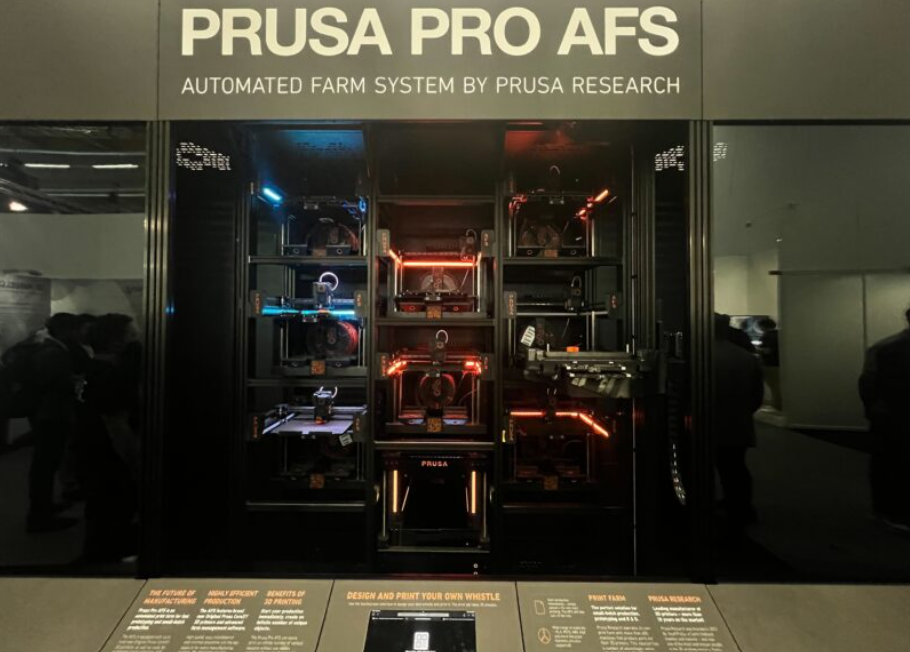

3D printer manufacturer Prusa Research announced the names of the first customers of its industrial 3D printing solution, named Original Prusa Pro Automated Farm System. MOTOISM (custom-made motorcycle parts, Germany), the Ruhr-Universität Bochum (education, Germany), SCHLEIF-TEC (prototyping, Austria), and Oratek (innovative technological solutions, Switzerland) are reportedly the first customers.

Prusa Research also announced its price, starting at €45,000 / $50,000 (VAT excl.). The AFS also includes Prusa Connect software suitable for efficient print management and task planning. Maintenance plans and training courses are available for the Farm System, including on-site support and immediate printer replacement.

“The demand greatly exceeds our production capabilities, therefore, for the first phase, we have chosen companies that are geographically close to us and represent the application of 3D printing in various lines of business,” said Josef Prusa, the CEO at Prusa Research.

Prusa Research’s industrial portfolio

“We really appreciate that we managed to establish cooperation with such an interesting group of partners that are really going to utilize the capabilities of the AFS to the fullest. We expect really close cooperation and collecting a lot of feedback enabling us to improve our solution even further,” added the CEO of Prusa Research.

The Original Prusa i3 MK3 3D printer was previously completely improved by Prusa Research. The MK3’s novel features are primarily intended to help extend its usability and encourage laid-back users to adopt 3D printers. To that end, the MK3 includes a variety of smart sensors to assist pause and recovering prints whenever something goes wrong; an enhanced, adjustable print sheet to aid in post-processing; and other under-the-hood improvements that make the MK3 Prusa’s smartest 3D printer.

Furthermore, Prusa had announced the release of the Original Prusa XL, its largest desktop 3D printer. The FFF system, which was unveiled at Formnext 2021, has a build volume measuring 360 x 360 x 360mm, over four times bigger than the firm’s flagship MK3S+ and eight times larger than the MINI+. The XL is also Prusa’s first CoreXY 3D printer, with vibrations minimized for higher print quality on larger format print jobs. Furthermore, the printer comes with an optional tool changer add-on that allows users to incorporate up to five independent tool heads at the same time. As a result, the system is well-suited to producing multi-material prints with up to five different filaments at the same time.

At Formnext 2022, Prusa Research introduced some other new products. For instance, the SL1S Medical printer from Trilab company and designed for dental labs, or industrial, delta-technology 3D printers. Prusa Research holds an 80% share of Trilab.

“We still want to focus primarily on individual customers, small businesses, and hobbyists. However, we also see increased demand from larger business customers that are becoming fed up with overpriced 3D printing solutions. It makes sense to cater to this demand, too,” added the CEO of Prusa Research.

Furthermore, Prusa Research presented new printing materials of the prevalent Prusament brand, which consist of bio-based and flexible 3D printing resins and the Prusament Refill, an environmental-friendly option for refilling the existing 3D printing filament spools.

Print farm systems

Previously, BCN3D Technologies, a Barcelona-based manufacturer of open-source 3D printers and developer of Independent Dual Extruder (IDEX) technology, had put out a video of its print farm. The print farm runs around the clock utilizing 63 BCN3D 3D printers. BCN3D designs, manufactures, and sells desktop 3D printers, namely the BCN3D Sigma and BCN3D Sigmax. The BCN3D Print Farm produces 47 pieces for each 3D printer using additive manufacturing – says the company.

Furthermore, 3D Printing Tech, based in Atlanta, had revealed the strategic acquisition of 3D printing service provider and competitor Voodoo Manufacturing, which shut down in 2020. The transaction enabled 3D Printing Tech to keep offering 3D printing services to the general public and boost its growth, bringing the company one step closer to operating one of the largest fused deposition modeling (FDM) printing farms in the United States.

Elsewhere, Czech automotive company Škoda revealed that it had been using 3D printing to simplify its automotive business, bringing prototypes, spare parts, and tooling in-house. The company set up several print farms using systems developed by companies such as Prusa as part of its ‘More flexible with 3D print farms’ project. Confederation of Industry of the Czech Republic had recognized Škoda’s additive manufacturing initiative, naming it one of the country’s five most innovative Industry 4.0 applications since 2020. Furthermore, the company announced plans for its ‘FORCE – Future Factory’ initiative, which would see Škoda increase its digitization efforts at many of its manufacturing facilities.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image displays representatives of MOTOISM and SCHLEIF-TEC with Josef Průša at the Formnext 2022. Image via Prusa Research.