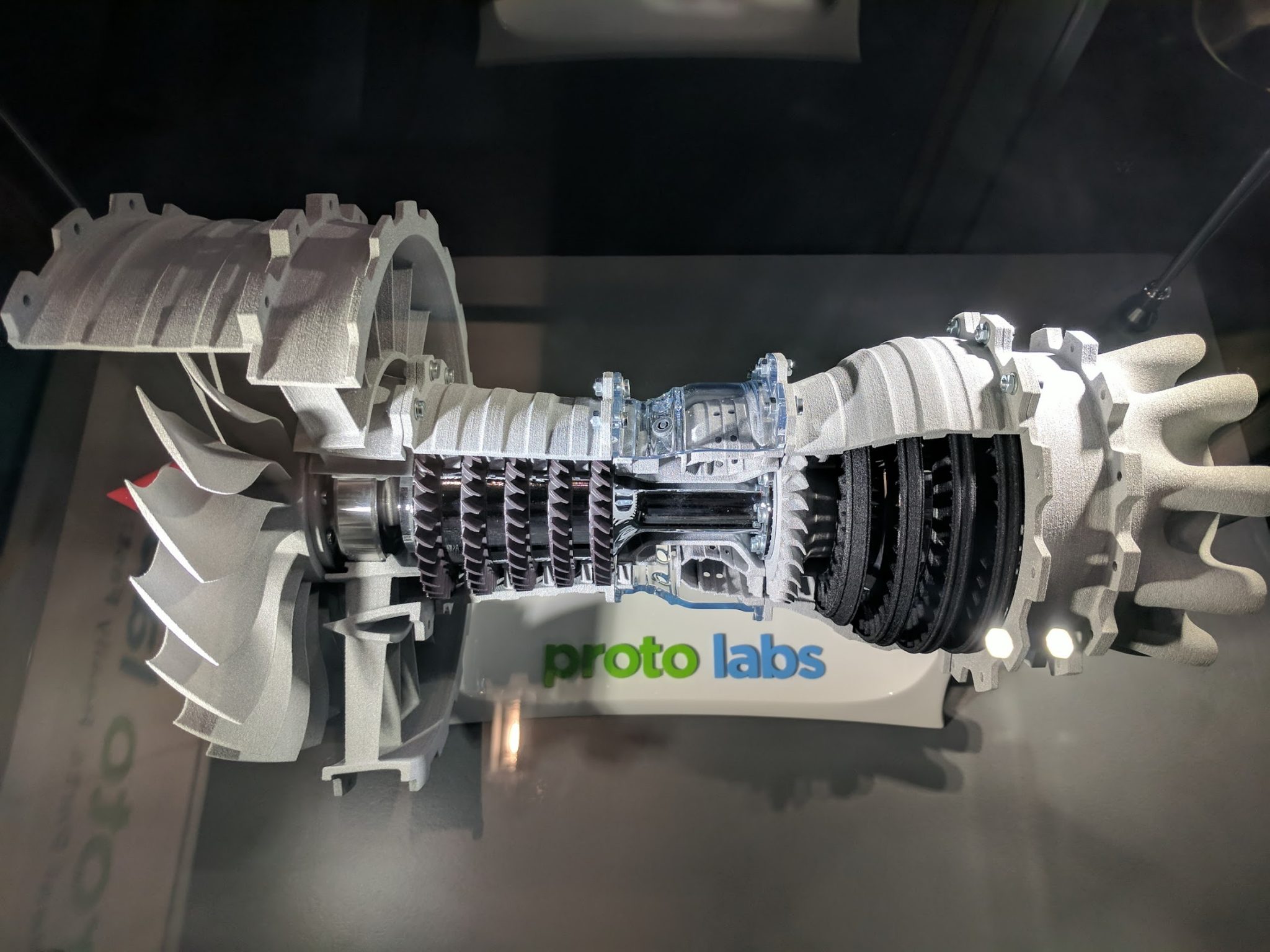

Protolabs, a manufacturing and 3D printing service bureau based in Minnesota, has become a founding member of the new Massachusetts Institute of Technology (MIT) Center for Additive and Digital Advanced Production Technologies (ADAPT).

ADAPT focuses on scaling new manufacturing technology through research; the consortium consists of Renishaw, Autodesk, Volkswagen, Bosch, Formlabs, BigRep, Mimaki, Dentsply Sirona, General Motors, EOS, and ArcelorMittal.

“We’ve experienced firsthand the tremendous progress that additive manufacturing has made over the past decade, and we’re quickly approaching another important milestone in 3D printing’s rapid ascent into industrial manufacturing space,” said Vicki Holt, President and CEO at Protolabs.

“My hope is that ADAPT will not only evolve additive manufacturing as a viable digital manufacturing solution for prototyping, but also end-use production. We are thrilled to be a founding member of ADAPT to help make that a reality.”

The ADAPT center

The ADAPT center was established by John Hart, Associate Professor of Mechanical Engineering and Director of the MIT Laboratory for Manufacturing and Productivity. The aim of the center is to accelerate the implementation of additive manufacturing and to “invent its future.”

The center will work in tandem with MIT educational programs such as “Additive Manufacturing for Innovative Design and Production,” which is supported by Protolabs.

“AM — and the path toward a responsive, digital manufacturing infrastructure both within and between organizations — requires multidisciplinary expertise at the cutting edge of mechanical engineering, computer science, materials, and other fields,” explained Professor Hart.

“I am thrilled to launch ADAPT to accelerate MIT’s efforts toward enabling the next generation of production technologies, wherein AM is a cornerstone.”

Within the facility, MIT experts and consortium partners are developing and critically assessing the status of 3D printing from robotics, advanced materials, to computational intelligence. The ADAPT center is also seeking to develop model-based decision tools and open strategic frameworks, as well as an academic-industry network.

As well as the ADAPT consortium, earlier this year, Protolabs joined the GE Additive Manufacturing Partner Network (MPN) to further advance and democratize access to industrial-grade additive manufacturing technologies and materials.

Make your nominations for the 2019 3D Printing Industry Awards here.

Also, for all the latest 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Make your next additive manufacturing career move or hire new talent. Search and post 3D Printing Jobs on our free jobs service.

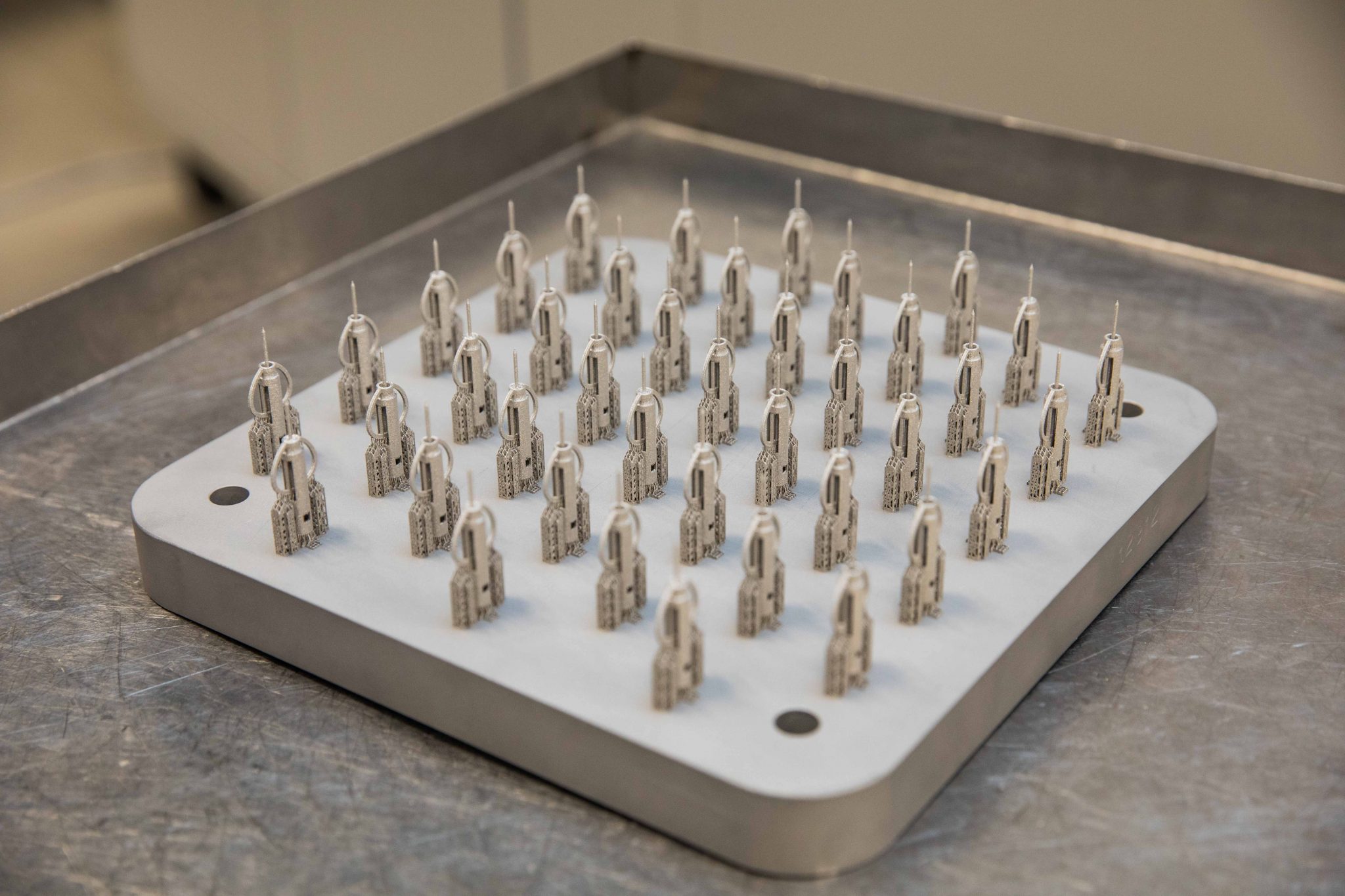

Featured image shows a bed of DMLS 3D printed parts. Photo via Protolabs.