French 3D printer manufacturer and service provider Prodways has started offering Oqton’s AI-powered software with its machines.

Oqton’s platform leverages AI algorithms to continuously improve production efficiency, learning from previous prints, and automatically adjusting parameters to fine-tune future parts. The software’s addition could now enable users of Prodways’ machines to automate their build preparation phase, improving machine throughput, while resolving any errors via a now-enhanced cloud-based platform.

“Adding Oqton means that our customers now have a comprehensive and intuitive one-stop platform that gives them a complete overview of the production chain and machinery,” said Alban d’Halluin, CEO of Prodways. “Our aim is for customers to manage their 3D production easily and with maximum flexibility.”

Software-driven automation

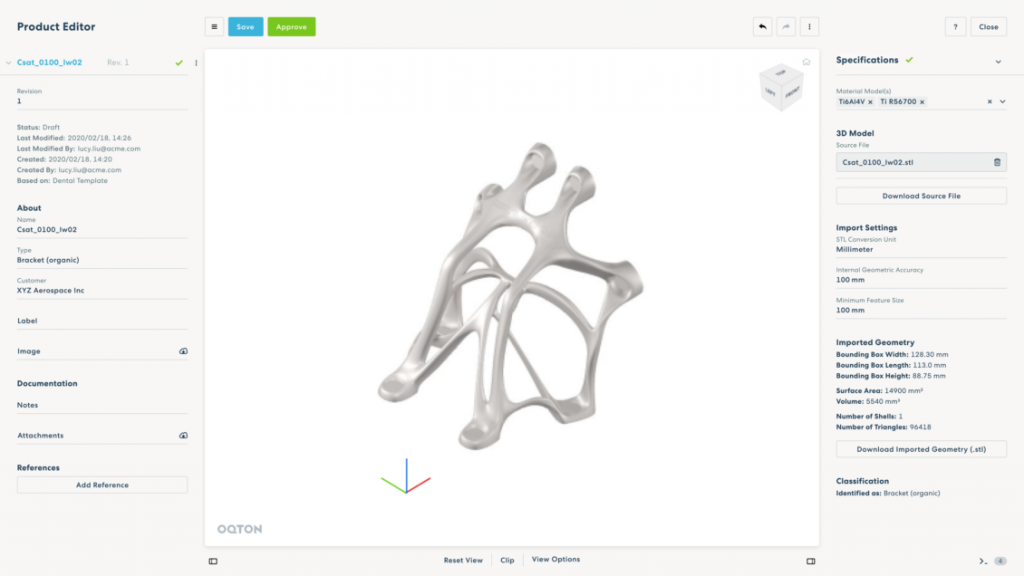

Based in California, Oqton focuses on the development of its proprietary software platform, which is designed to allow users to streamline, manage and scale their production workflow. At its core, the program is led by an AI-powered Manufacturing Execution System (MES), that’s capable of automatically readying parts for printing, as well as expediting file preparation.

Utilizing an advanced ML algorithm, the software essentially ‘learns’ from continued usage, to provide adopters with component orientation suggestions and support strategies, that reduce time spent on repetitive tasks. Following extensive use, Oqton says that its program can even mimic the actions of experienced operators, allowing engineers to invest their time elsewhere, adding value to their businesses.

The firm’s platform also includes a cloud-based IoT interface that enables users to monitor, control and automate their systems across multiple sites, making scaling easier to achieve. Similarly, the software’s process simulation tools provide manufacturers with material usage and lead time predictions, allowing them to plan well ahead and prioritize urgent jobs.

Earlier this year, Oqton raised $40 million towards the growth of both its platform and commercial partnerships across 3D printing, welding and CNC machining. Having already worked with EOS, Sisma, TRUMPF and Sandvik, the firm has now collaborated with Prodways, to incorporate its software into the firm’s machines.

A “win-win relationship”

Working with Prodways’ dedicated Printers division, Oqton has successfully integrated its cloud-based platform with the French firm’s machines, allowing users to access their workflow on any smart device. According to d’Halluin, the program is therefore ideal for use within the post-pandemic world, where remote working has increasingly become the norm.

“The COVID-19 crisis has made this all the more essential, now that working from home is on the rise and people need to access data and assets from wherever they are,” said d’Halluin. “Oqton is hosted on the cloud, which makes it the ideal solution, as customers can interact with Prodways machines from anywhere at any time.”

Leveraging Oqton’s software, Prodways anticipates that its users can reduce any time spent conducting part nesting, from an average of one hour down to just ten minutes. As an added benefit, the automation provided by the program’s AI algorithm may even minimize expensive human errors, as well as cutting machine downtime via predictive maintenance.

“We are delighted to be working with Prodways and offering them a new approach to managing 3D manufacturing processes,” concluded Ben Schrauwen, CEO of Oqton. “With our solution, Prodways customers should see immediate gains in production efficiency and quality. This deep and far-reaching integration of our software into the Prodways range is unique in the industry and an illustration of how this is a win-win relationship.”

AI-powered automation tools

AI and ML-based software has huge potential when it comes to driving efficiency and quality from 3D printing-based setups, and the technology has made significant advances in recent months. Researchers based at Oak Ridge National Laboratory (ORNL) have managed to develop an AI program called ‘Peregrine,’ that’s capable of in-process metal 3D printing monitoring.

3D printer manufacturer Markforged has also embraced ML programming with the launch of its AI-based Blacksmith software. Specifically designed for use with the company’s X7 3D printer, the platform incorporates a patented scanning algorithm, that measures part accuracy and makes changes to improve future reliability.

Recognizing the growing role of AI within production, a report by Lux Research recently revealed that AI-enabled sensors are the fourth-best technology to watch heading into 2021. According to the paper’s lead author, the devices could help to “bring businesses back to work” as pandemic restrictions start to ease this year.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a close-up of a Prodways 3D printer. Photo via Prodways