PostProcess Technologies, a provider of automated post-processing systems for 3D printed parts, has joined the partner ecosystem of 3D printer OEM Carbon.

The deal will see PostProcess’ proprietary resin removal technology made compatible with Carbon’s leading DLS 3D printing platform, giving Carbon customers access to a more streamlined, scalable, end-to-end workflow. Furthermore, the partners have stated that they will continue to collaborate on future printers and resins, boding well for high-volume manufacturers in need of polymer parts.

Interestingly, 3D printer manufacturer Stratasys also recently announced that it will begin offering DyeMansion post-processing systems via its extensive network of channel partners. With the Stratasys channel network being the largest in the 3D printing industry, the moves signal the ongoing adoption of industrial post-processing systems (and 3D printing as a whole) throughout the wider manufacturing sector.

Jeff Mize, CEO of PostProcess Technologies, said, “We are delighted to announce this partnership with Carbon, a world-leading innovator in the additive manufacturing market, to pair our proven resin removal technology with their platform. We have very similar ‘customer-first’ cultures which we believe will result in this alliance being transformative for Carbon users to streamline and optimize their complete 3D printing workflow.”

The DEMI 910

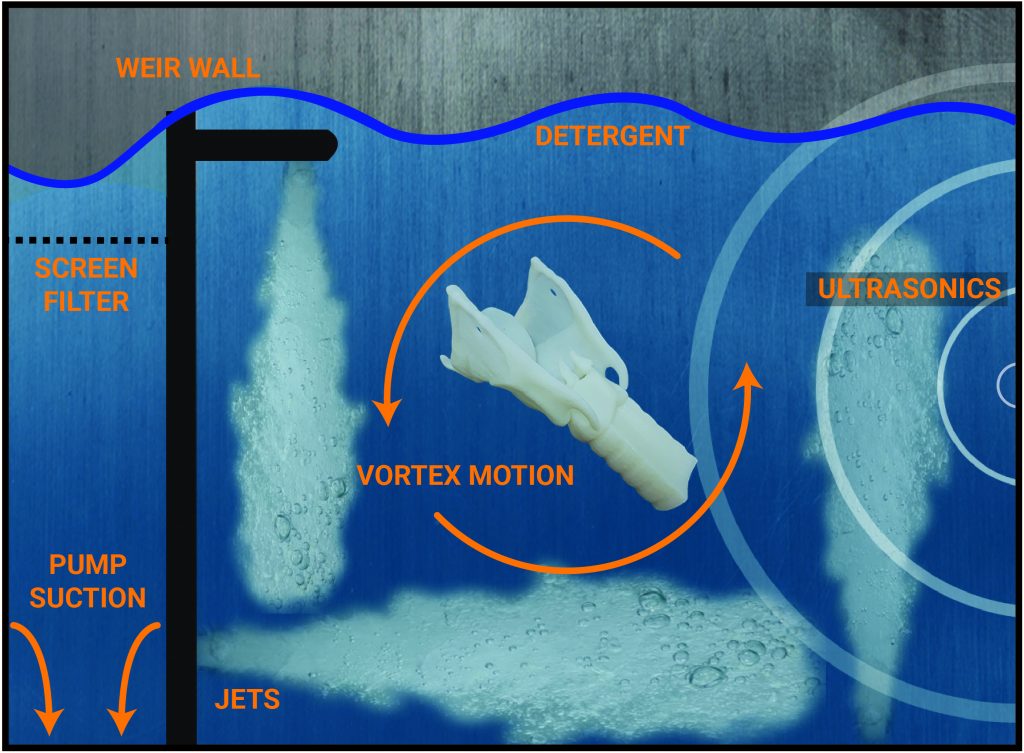

The first of the partner products will be the DEMI 910, an automated resin removal system operating on PostProcess’ Submersed Vortex Cavitation (SVC) technology. The system will utilize a combination of ultrasonic waves, a vortex pump, and specially-formulated detergents to rotate fully-submerged parts in a large processing chamber. The patented resin removal process is optimized via both chemical and mechanical energy.

PostProcess’ DEMI 910 will be able to process an entire Carbon L1 printer build or up to two Carbon M2 printer builds at once, and will leverage new Carbon-specific detergents. Much like the rest of the DEMI portfolio, the system will be driven by the company’s AUTOMAT3D software platform, which uses proprietary agitation algorithms to closely control energy, speed, direction, and temperature to avoid breakages and other failures.

“We are excited to have PostProcess as a part of the Carbon partner ecosystem. As we build a global ecosystem that is opening up the world of manufacturing, we strive to partner with companies that have complementary offerings to streamline the product development lifecycle,” said Phil DeSimone, Chief Product & Business Development Officer at Carbon. “This partnership will expand the post-processing options available to product developers using the Carbon platform.”

The rise of automated post-processing

The expansion of specialist post-processing systems lags behind 3D printer purchases given the fact that such solutions become more valuable once throughput increases. However, with companies like PostProcess and DyeMansion entering major partnerships and signing distribution deals, the industrialization of high-throughput 3D printing could be edging closer.

Just last month, PostProcess also partnered with South Dakota-based 3D printing service bureau Primary Manufacturing to provide its DEMI 430 automated resin removal system. The machine will be integrated into Primary Manufacturing’s digital thread to bolster its resin 3D printing processes with increased productivity levels.

Elsewhere, at last year’s Formnext Connect, DyeMansion announced its own series of collaborations specifically aimed at industrializing additive manufacturing. The firm partnered with industrial manufacturing firm Siemens to integrate its automation technology, while also revealing 3D printing service providers Paragon and the Digital Manufacturing Centre (DMC) in the UK as production partners. The news was followed by the launch of three new PowerShot post-processing systems.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Carbon’s L1 3D printer. Photo via Carbon.