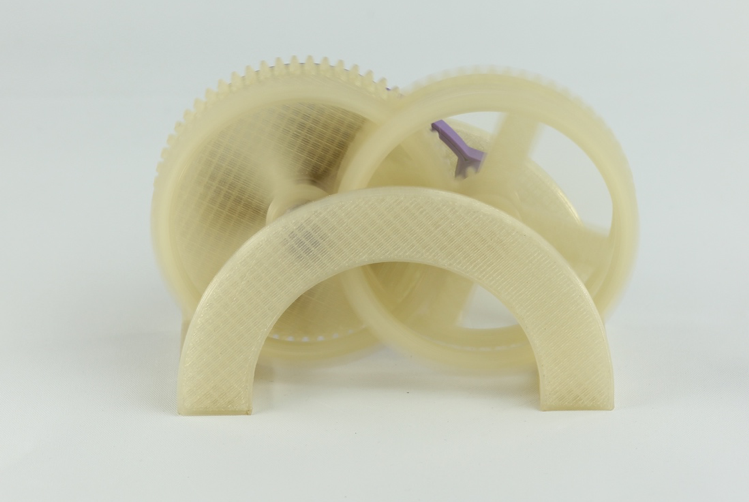

3D printer materials company Polymaker has launched PolyMide CoPA, a series of nylon (polyamide)-based 3D printer filaments that are optimized for engineering applications with “Warp-Free” technology.

PolyMide CoPA is the latest material from award winning 3D printing filament supplier Polymaker since it launched two new TPU-based filaments last year. The new material will be available in Black and Natural colors.

Chasing the Warp away

Nylon filament, although highly tensile and resistant to abrasion, has often been overlooked in FFF/FDM 3D printing. This is because of relatively poor dimensional stability (i.e. the degree to which it retains its original dimensions under heat and humidity changes) and tendency to warp when extruded.

PolyMaker’s Warp-Free technology addresses these issues by chemically controlling the microstructure and crystallization behavior of the filament when it is manufactured. As a result, all internal stress built up during 3D printing is fully released prior to solidification.

When 3D printing the new Polyamaker material, it does not require a heated chamber, meaning that it can be printed on any FFF/FDM 3D printer capable of achieving a nozzle temperature of 250°C or higher.

Additionally, the improved printability is achieved without sacrificing the intrinsic properties of nylon, and no addition of abrasive fillers that may damage the 3D printer nozzle.

An improved engineering plastic

Nylon is useful for producing working parts and moving assemblies that feature increased stress resistance, high heat deflection, effective layer adhesion, and high tensile strength.

As a proof of concept, researchers at Tongji University built an eco-car that combined 3D printed nylon parts with carbon fiber panels. The ability to 3D print large nylon parts with custom infill patterns allowed the balancing of weight distribution within the eco-car.

“We are very excited about the material and the new applications it enables”, said Dr. Xiaofan Luo, Polymaker CEO, “it further bridges the gap between engineering plastics and desktop 3D printing.”

Polymaker, winners of 3D Printing Industry’s 2017 Materials Company of the Year award, will make PolyMide CoPA Black available Worldwide on the 22nd of January 2018, and PolyMide CoPA Natural in March 2018.

Make your nominations for the 2018 3D Printing Industry Awards now.

For more stories on 3D printer materials subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows PolyMide CoPA filament inside a PolyBox. Photo via Polymaker.