3D printing materials company Polymaker has launched its latest PLA-based filament for 3D printing, PolyTerra PLA, which has been developed to be tougher and impart less of an environmental impact.

To achieve this, Polymaker has significantly reduced the amount of raw PLA in the creation of the filament by compounding it with organic materials. As a result, the PolyTerra PLA possesses greater toughness properties and gives a matte finish to 3D printed parts.

Using naturally-sourced compounds

In order to reduce the man-made processes involved in creating the bioplastic material, Polymaker sourced and blended naturally-occurring organic elements that would deliver desired mechanical properties such as toughness and impact-resistance to 3D printed parts. By reducing the plastic content in the material by around 40 percent, the firm claims it has achieved a more environmentally-friendly filament without compromising its printing performance.

The organic elements compounded into the PolyTerra PLA filament provide a matte finish to 3D printed parts, which can be enhanced by 14 available color options including four new pastel colors which can absorb light on printed parts to hide layer lines and provide a smoother surface finish.

Polymaker has run a compostability test, certified to ISO 14855-1, with a third party laboratory that revealed PolyTerra PLA degraded faster than a comparable PLA material, achieving around 77 percent degradation after 45 days in test conditions.

To add to the environmentally-friendly aspect of its new material, Polymaker has teamed up with global reforestation non-profit One Tree Planted to offset the carbon created in the manufacturing and shipping of PolyTerra PLA spools. For every spool sold local to the point of purchase, Polymaker will plant one tree, which when reaches maturity in around 10 years will be able to absorb 22kg of carbon dioxide from the atmosphere each year.

Furthermore, the PolyTerra PLA is wound on a recycled cardboard spool with recycled labels and outer packaging, and Polymaker has removed unnecessary waste from the product by moving all its information sheets online.

Mechanical features of PolyTerra PLA

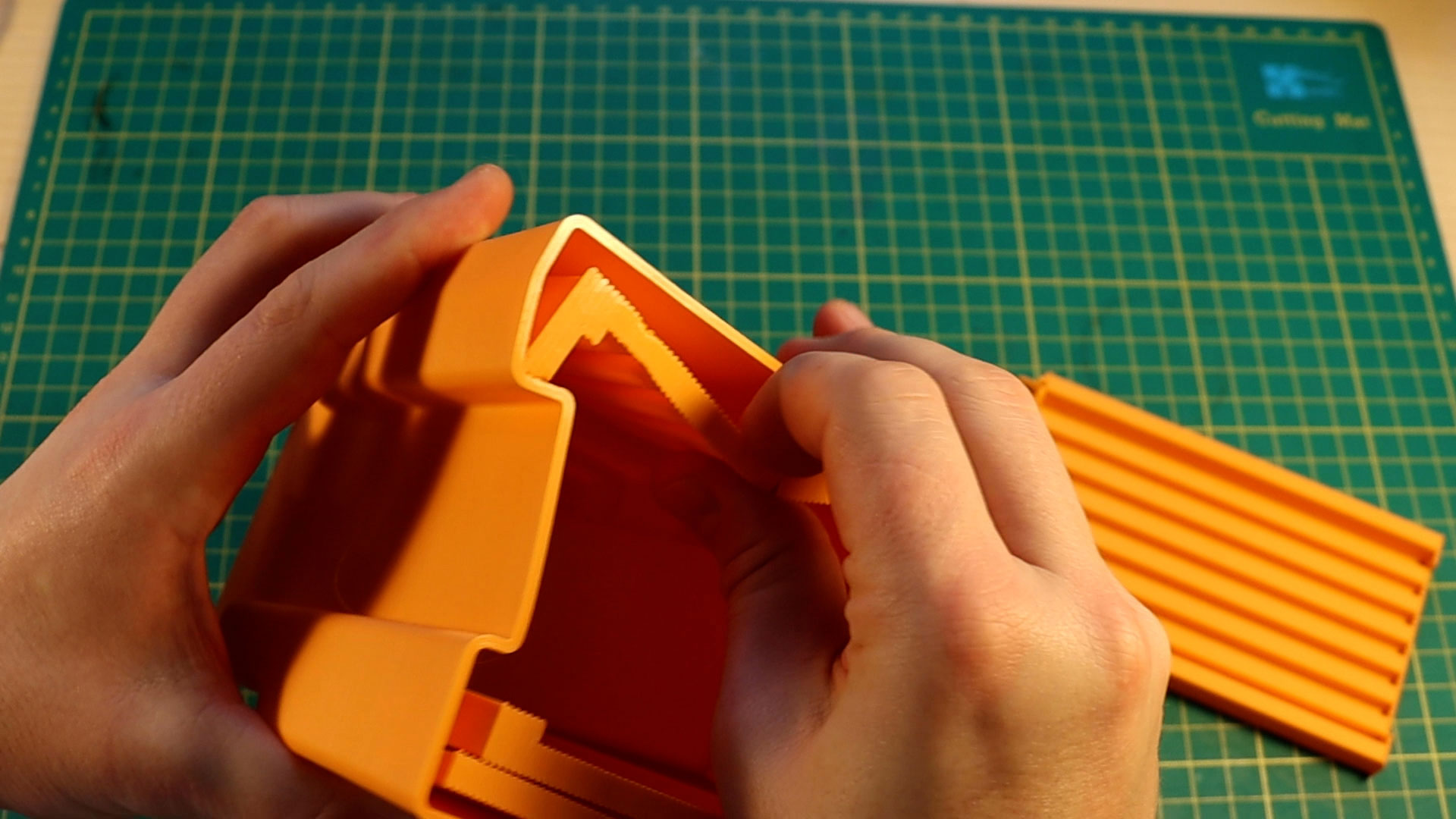

PolyTerra PLA is compatible will all extrusion-based 3D printers using PLA settings. Supports can be removed from the 3D printed part easily and without the use of tools, enabling users to quickly clean up parts with complex geometries. According to Polymaker, the printed supports enable single extrusion 3D printers to produce a wide range of shapes and details.

During post-processing, parts printed with PolyTerra PLA can be sanded quickly and with power sanders without the plastic ‘chewing up’ or rolling over into long beads, due to the material’s soft surface finish. Open pores on the printed part’s surface help paints to maintain a strong bond to the part’s exterior, and a wide array of paints can be applied due to the material’s inert nature.

With the new material, Polymaker is targeting consumers within the less than $500 3D printer price bracket, as a result of a significant boom in sales in this area over the past year. The MSRP for 1kg PolyTerra PLA is $19.99.

Environmentally friendly material production

Polymaker has previously sought to explore more environmentally-friendly production processes, having teamed up with high-performance polymer manufacturer Covestro for the development of waste-free 3D printed fabrics. The partners claim the 3D printing of fabric is a more environmentally friendly alternative to traditional weaving, as the method produces no excess fabric that needs to be cut off and discarded.

At Formnext Connect 2020, Covestro debuted a new, more sustainable line of 3D printing materials with the aim of addressing the circular economy of its products. The new materials are either partially made from recycled plastics or with up to 20 percent CO2, and aim to build on the potential environmental benefits of 3D printing.

Elsewhere, natural materials have been used in the construction sector to 3D print eco-friendly houses, 100 percent recycled filaments from waste material are under development, and ‘electron-eating’ microbes have been 3D printed into biofilms with the potential to create a generation of eco-friendly biofuels.

Recently, a Smart Fusion Material Research Cluster was formed to investigate sustainable material design and manufacturing processes for metal 3D printing.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed sandcastle molds in PolyTerra PLA. Photo via Polymaker.