Orthofix Medical, a Texas-based developer of 3D printed orthopedic devices, has launched its new FORZA Ti PLIF Spacer System.

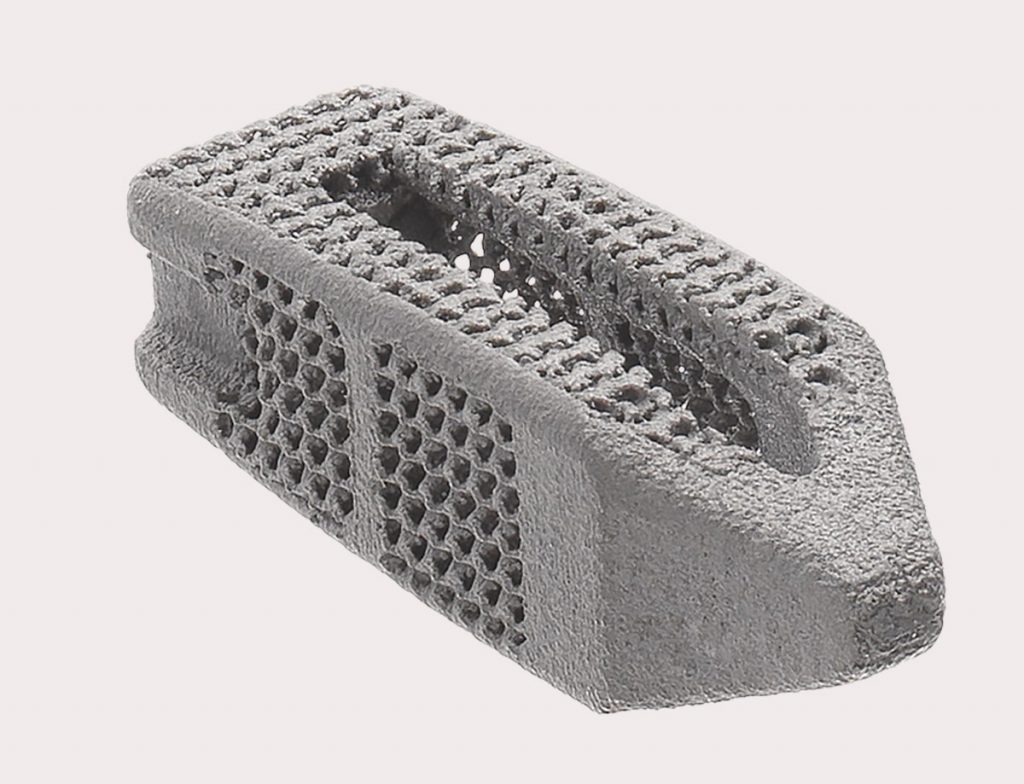

Designed for use in Posterior Lumbar Interbody Fusion (PLIF) surgeries, the titanium implant features a complex 3D printed geometry, a porous structure, and a nanoscale surface texture that promotes bone growth through the spacer. As well as the product launch, Orthofix Medical has also announced the first patient implant using the lumbar interbody device, with more to come.

“The FORZA Ti PLIF Spacer System, featuring Orthofix’s unique Nanovate Technology, is one of several new 3D printed titanium products we have launched recently,” said Orthofix President of Global Spine Kevin Kenny. “The FORZA Ti system is also ideal for use with our flagship Trinity ELITE allograft with viable cells that supplies the essential components for new bone formation.”

Posterior Lumbar Interbody Fusion

PLIF is a form of lower-back spinal fusion surgery, whereby a bone graft or synthetic cage is added to an area of the spine to initiate a biological response that promotes bone growth between two vertebrae.

Unlike some other forms of spinal fusion, PLIF often requires an interbody device to be inserted between the vertebral elements, which helps relieve pressure on the local nerves while holding the vertebrae in place for fusion to occur. The FORZA Ti PLIF Spacer System is a prime example of such a device.

According to Dr. Joel Siegal, the neurosurgeon at St. Vincent Charity Medical Center who performed the first FORZA implant procedure, “Being able to maximize bone ingrowth is critical to the success of the fusion process. The large opening for packing bone grafting materials and the 3D printed titanium endplates of the FORZA Ti Spacer are well designed to aid in our goal of maximizing bone ingrowth to aid fusion.”

The FORZA Ti PLIF Spacer System

On top of the large open graft window, the FORZA Spacer System has a number of in-built features designed to improve success rates in PLIF procedures. This includes a bulleted nose to enable easier spinal distraction. The titanium structure of the implant also has nanoscale surface textures that have been shown to improve bone proliferation, as well as alkaline phosphatase activity in human stem cells (this is an early bone cell differentiation marker).

Additionally, the porosity of the implant’s midline sits at 80%, which allows for increased fluoroscopic visualization. Meanwhile, the 50% porosity endplates feature an interconnected gyroid structure and 400 micron pores to help facilitate better bone ingrowth.

As well as the FORZA Ti PLIF Spacer System, Orthofix has also recently launched a number of other 3D printed medical devices, such as the CONSTRUX Mini Ti Spacer System, CONSTRUX Mini PTC Spacer System, and Pillar SA PTC Spacer System.

Additive manufacturing has well and truly found its place in the medical sector, with end-use implants now being 3D printed. Onkos Surgical, a provider of orthopaedic oncology medical devices, recently received 510(k) clearance from the Food and Drug Administration (FDA) for its portfolio of modular 3D printed BioGrip collars. Much like the FORZA Spacer, the porous medical devices are designed to support bone growth in bone cancer survivors and other complex limb salvage cases.

Elsewhere, in the materials space, metal 3D printing specialist Z3DLAB recently revealed that it’s currently developing “a new generation of materials” with enhanced biocompatibility and potential 3D printed implant applications. Working with a consortium of French CNRS academics, the company will develop a ‘complex concentrated alloy’ with the properties required for SLM 3D printed surgical grafts.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed FORZA Ti PLIF Spacer System. Photo via Orthofix Medical.