Researchers at Oak Ridge National Laboratory (ORNL) have announced the development of a novel water-soluble plastic binder that can be added to 3D printing materials and jetted into parts with “exceptional strength.”

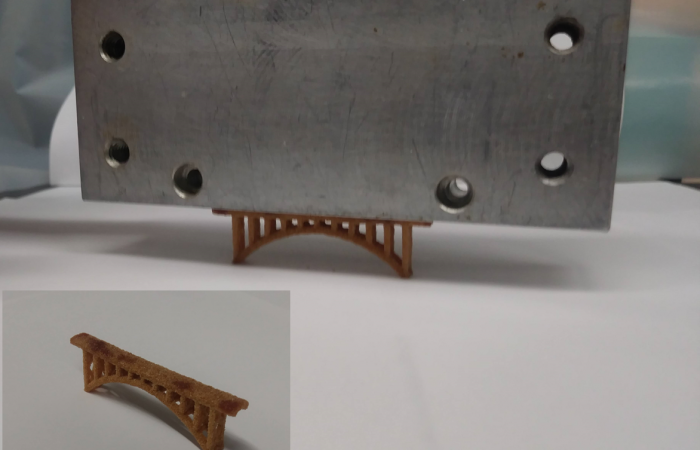

By tweaking a high-amine content, low molecular weight polyethyleneimine (PEI), the ORNL team has been able to tailor its properties in a way that doubles its strength compared to conventional binders. To showcase the capabilities of their new material, the scientists have already used it to bind and strengthen silica sand, before 3D printing it into a bridge capable of holding 300 times its own weight.

“Few polymers are suited to serve as a binder for this application,” said Tomonori Saito, one of the lead researchers on the project. “We were looking for specific properties, such as solubility, that would give us the best result. Our key finding was in the unique molecular structure of our PEI binder that makes it reactive with cyanoacrylate to achieve exceptional strength.”

Binder jetting’s tooling potential

According to the ORNL team, binder jetting is both “cheaper and faster than other 3D printing methods used by industry,” thanks to its broad powder compatibility and scalable workflow. In particular, the researchers identify the technology’s ability to process low-cost sand as being ideal for the high-throughput production of industrial tools and dies.

However, the scientists also see the mechanical weakness of green binder jetted parts as a “major bottleneck,” that prevents their widespread adoption in this area. When it comes to reinforcing such parts, binders are a vital element of materials used, that defines their outright strength, but the composition of these often feature limited interactions between the polymer and sand, thus their reduced resistance.

“To ensure accuracy in tooling parts, you need a material that does not change shape during the process, which is why silica sand has been promising,” explains University of Tennessee student and the study’s lead author Dustin Gilmer. “The challenge has been to overcome structural weakness in sand parts.”

In terms of existing 3D printed sand casting molds, the team say that they have limited industrial applications, because once heat and pressure is applied to them, they can be subject to breakage. To enable the production of more robust, scalable, end-use ready binder jetted parts, the ORNL researchers have therefore identified the need for a material that better fuses binders and powders together.

A new binder on the block?

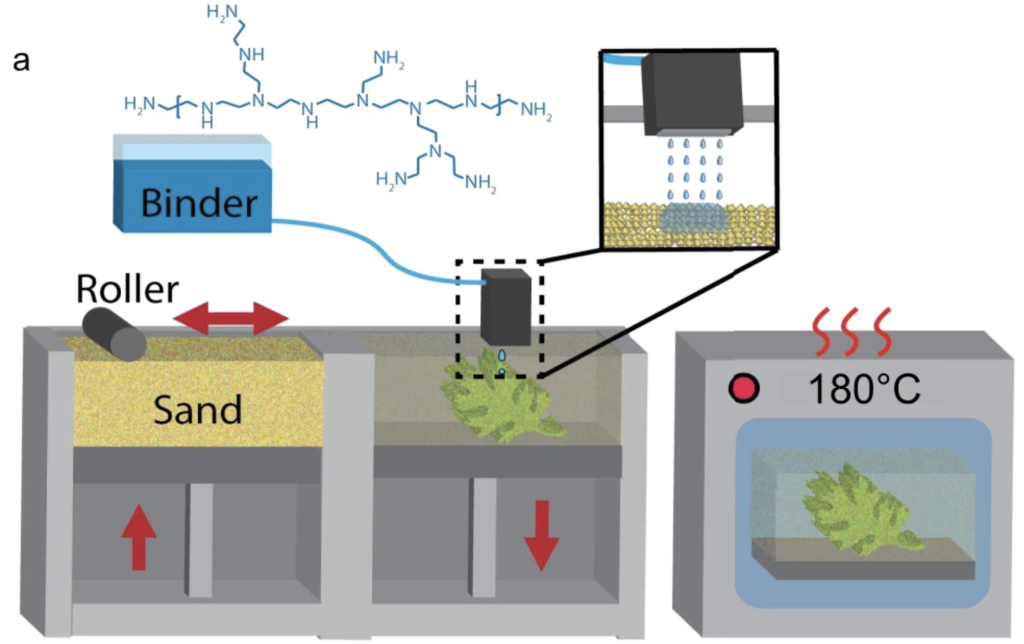

To get around the drawbacks of conventional binders, the scientists created theirs from a ‘hyperbranched’ PEI with a high quantity of carbon-nitrogen amines, that allow it to achieve strong interfacial interactions. The material’s structure has also been formulated to provide it with low viscosity, high solubility and limited crystallinity, making it ideal for piezoelectric drop-on-demand binder jetting.

Interestingly, by experimenting with the PEI loadings of their binder, the team say they’ve been able to optimize its printability too, and achieve “a near-linear increase in green part strength.” Through prototyping, the researchers found that printing parts with a 5.5% PEI concentration, provided them with a strength of 6.28 MPa, well above the 3.60 MPa they were able to achieve with commercial binders.

Due to the inherent porosity of binder jetted parts, the team also discovered that they were able to increase the strength of sand components via the integration of a secondary polymer. By adding ethyl cyanoacrylate (ECA), for instance, the scientists managed to create a material that could be 3D printed into a 6.5cm bridge with a flexural strength of 53 MPa, making it stronger than brick-and-mortar.

As an added benefit, this ECA-infused binder proved to be water-dissolvable as well, thus its creators say it could have extensive ‘washout tooling’ applications. Specifically, the team expects such devices to have significant potential within the creation of optimized ducting and sandwich panels in the aerospace and defense industries, verticals they expect to grow to a value of $7 billion by 2025.

Overall, Gilmer argues that the high-strength polymer sand composite the ORNL team has created, effectively “elevates the complexity of parts that can be made with binder jetting,” and enables the production of intricate hollow forms that “widen [the technology’s] applications for manufacturing, tooling and construction.”

Since the binder was introduced, it has received an R&D 100 Award and been licensed by ExOne, where it continues to be used for research purposes.

Advancing binder jet production

The binder jet printing market may have been consolidated by Desktop Metal’s acquisition of ExOne earlier this year, but the technology continues to make progress elsewhere too, with several advances being made in the last year alone.

Voxeljet, for instance, has revealed that it’s lending its binder jetting expertise to the construction of what is set to be the world’s largest wind turbine 3D printer. The new system is specifically being built to print the molds needed to cast large-format parts for GE’s Haliade-X offshore turbine, which can weigh a colossal 60 tons each.

GE Additive, meanwhile, continues to make progress with its own H2 binder jetting system, and the company announced a collaboration with the Indiana Economic Development Corporation (IEDC) last year. Through the deal, the organizations agreed to co-invest in the technology’s R&D, and unleash its potential to advance the region’s factory automation as well as improving its manufacturing readiness.

On a smaller scale, UK-based Meta Additive has also made progress with the development of its proprietary binder jetting technology. The firm gained a £1.2 million Innovate UK grant to fund the R&D of its high-density, low-shrinkage process in December 2020, and the start-up now has ambitions of marketing it to automotive, aerospace and medical clientele.

The researchers’ findings are detailed in their paper titled “Additive manufacturing of strong silica sand structures enabled by polyethyleneimine binder,” which was co-authored by Dustin B. Gilmer, Lu Han, Michelle L. Lehmann, Derek H. Siddel, Guang Yang, Azhad U. Chowdhury, Benjamin Doughty, Amy M. Elliott and Tomonori Saito.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an ORNL scientist Tomonori Saito showing off a sandcastle that was 3D printed using the novel binder. Photo via ORNL.