Origin, a California-based 3D printer provider, has announced that its Origin One system is now shipping to customers. Due to reported strong demand for the system, the company has moved into a larger office space in San Francisco, and made a new leadership appointment as well.

Furthermore, Origin has revealed that two 3D printing service bureaus, Avid Product Development and Interpro Models, have added Origin’s programmable photopolymerization (P³) 3D printing technology to their platforms.

Chris Prucha, co-founder, and CEO of Origin, comments:

“Shipping our first production printer, Origin One, is a huge milestone for the company”

“The tremendous customer growth and demand we’ve seen for the printer, as well as the positive reception from our open material network, is extremely gratifying and proof that we’ve created a platform that our customers need.”

Are open materials the key to additive mass production?

Founded in 2015, Origin is focused on bringing mass manufacturing to the additive industry. The company official emerged from in stealth mode in 2018 with $10 million in series A funding, while also revealing the development of its Open Additive Production platform and P³ technology.

P³ enables voxel-level control over the 3D printing process in order to extract different mechanical performances out of a material. This allows customers to customize their print and how the part performs.

Open materials are central to Origin’s plans of making 3D printing a viable mass production method. Working with material developers, the company aims to create formulas specifically for Origin’s P³ technology, rather than Origin creating thousands of formulas for niche uses on its own. Origin has thus far introduced global chemical and material companies DSM, Henkel and BASF to the network in order to develop materials for Origin’s 3D printing technology.

The Origin One 3D printer

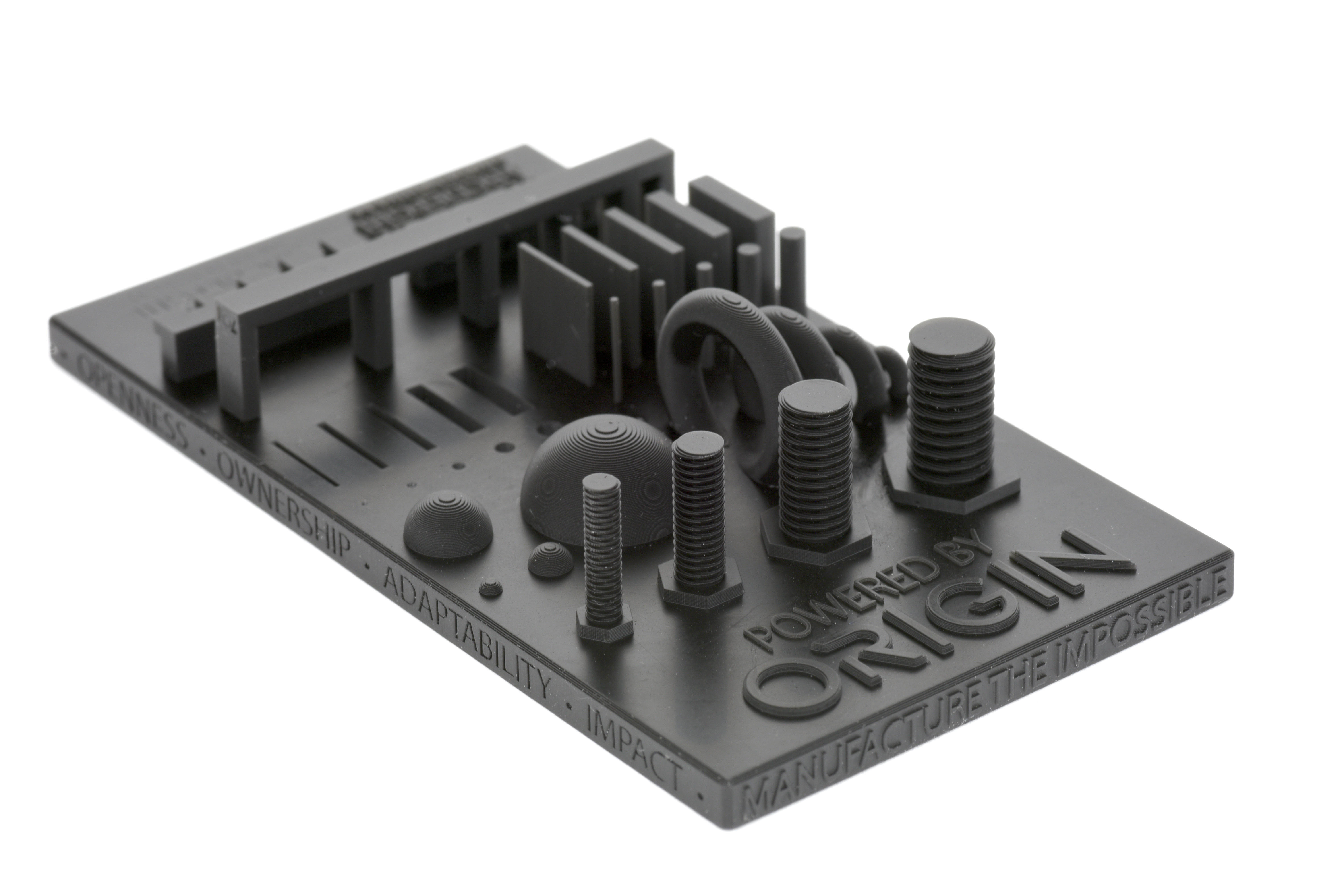

Origin’s new 3D printer, the Origin One, was initially introduced by the company in May 2019. An SLA/DLP machine, it is based on the company’s P³ process. It features a build volume of 192 x 108 x 350 mm, with open materials, modular hardware, and specialized software to automate the printing process.

“Equipped with a true 4k lithography engine and a native resolution of 50μm, Origin One has the highest resolution and most flexible polymer process available in additive manufacturing today,” explains Prucha.

Since the initial reveal in May, Origin has made further improvements to the Origin One system through software updates. These tweaks have reportedly increased the system’s usable build area, print speed, chemistry capabilities, and surface quality.

With the Origin One now shipping, the company is experiencing strong demand for the system. In the last six months, Origin claims to have more than doubled its 3D printer install, specifically with customers in the Global Fortune 500, in countries such as the United States, Ireland, Germany, and Denmark. Its customers operate in industries including footwear, automotive, contract manufacturing and government.

New COO and office space

To meet the growing demand, Origin moved to a new office in San Francisco three times the size of its previous location. The new office space also comes equipped with a larger lab, which will support the company in optimizing software and validating materials for the Origin One 3D printer.

Origin has also appointed Jeffrey Lee as its new Chief Operating Officer. Previously, Lee operated as a venture partner at DCM, and helped source Origin’s Series A investment in November 2018. “I’ve worked with this team for almost two years, and I’ve never been so convinced that Origin is poised to finally bring additive to mass manufacturing,” stated Lee. “I’m excited to join the team and help Origin realize this vision.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Origin One 3D printer. Image via Origin.