Industrial 3D printer manufacturer Optomec has received an order worth $2 million for six Aerosol Jet 3D Electronics printers from a leading aerospace and defense electronics systems manufacturer.

With the addition of the new 3D printers, the unnamed global company brings its total count to 20 systems as part of a production ramp plan to grow its operations to more than 30 systems in the next year.

“Optomec is fortunate that many of its customers are at the vanguard in adopting additive manufacturing in real-world production applications,” David Ramahi, Optomec CEO.

“This particular user is truly a standout in leading the charge when it comes to implementation of 3D additive electronics, having shipped 100,000s of products manufacturing using Optomec’s Aerosol Jet solution for advanced semiconductor packaging.”

Optomec’s Aerosol Jet 3D printing

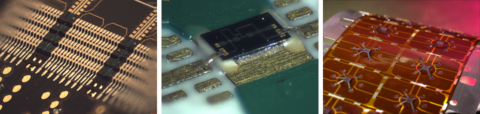

Optomec’s Aerosol Jet Printing (AJP) technology allows users to deposit electronic inks directly onto 3D surfaces and, when used to print conductive silver, lends itself to creating high-resolution circuitry for electronics.

Capable of realizing features as small as 10 microns in size, AJP powers Optomec’s AJ FLEX and Aerosol Jet HD2 machines to enable a wide array of electronics applications, including antennas, sensors, medical electronics, semiconductor packaging, and wrap-around display interconnects.

Last year, Optomec continued to develop the capabilities of its AJP technology through patenting a UV illumination technology to modify the mechanical properties of aerosol inks as they are deposited, in order to more precisely produce 3D microstructures.

Optomec’s AJP-powered systems have been adopted by several high-profile names in the electronics sector. For instance, Samsung has previously installed an Aerosol Jet 5X system to expedite its electronics production, while defense firm Northrop Grumman has leveraged AJP to devise a novel method of fabricating semiconductor interconnects. Optomec has since built on the defense company’s MMIC research to develop a signal-boosting interconnect solution that effectively doubles the output of 5G antennas.

Most recently, Optomec sold three of its AJP systems to a Fortune 500 leading media and technology OEM which is aiming to utilize the machines to develop and manufacture a new generation of wearable electronics.

Optomec’s $2 million AJP order

The latest order Optomec has received for its AJP 3D printers is from one of its existing production customers which has been using leveraging the technology for more than five years. Now, the global electronics systems manufacturer has purchased six additional AJP printers to bring its total portfolio of Optomec systems to 20.

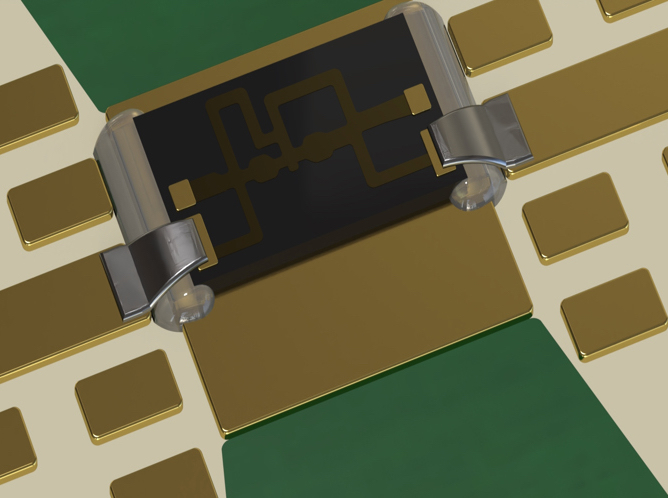

The latest order, worth $2 million, is reportedly part of a plan to ramp up production by the manufacturer as it looks to increase its number of systems to more than 30 over the next 12 months. The order includes the client’s first installations of Optomec’s HD2 Electronics 3D printer, which is specifically tailored for inline production in advanced semiconductor packaging and printed circuit board (PCB) assembly operations.

For these particular applications, a high-value use case for AJP is the additive manufacturing of 3D interconnects to connect chips to other chips, circuit boards, and directly integrated into end products like wearable electronics. In cases such as this, AJP provides advantages over legacy wire-bonding techniques in terms of smaller space claim and greater mechanical reliability.

Under the contract, Optomec will deliver production “recipes” for both conductive and insulating materials to the electronics systems manufacturer.

To date, Optomec has delivered over 500 additive manufacturing systems to more than 200 customers across the globe. These systems have been utilized for a wide range of production applications within the electronics, energy, life sciences and aerospace industries, among others.

The progression of 3D printing electronics

While the 3D printed electronics sphere is still in its nascent stage, a number of companies are seeking to establish themselves as leaders in the field.

One of those is Nano Dimension, which has recently made significant progress with its DragonFly systems and software after entering into a partnership with Fraunhofer IPA to advance freeform printing and assembly capabilities. At the beginning of this year, Nano Dimension took another significant step forwards with the acquisition of Global Inkjet Systems (GIS) in a deal worth up to $28.8 million.

Elsewhere, microdispensing specialist nScrypt recently showcased the ability of its microdispensing ‘SmartPump’ toolhead to 3D print electronics onto curved surfaces, and German electronic 3D printing firm Neotech AMT hinted at the further development of its “fully additive” electronic devices and the upcoming reveal of a scalable 3D printing process for 4D mechatronic systems as part of the EU-backed AMPERE project.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Semiconductor Packaging examples showing Printed 3D Interconnects for 3D stacked die, mmWave, and flex circuit. Image via Business Wire.