It looks like Optomec, a leading global supplier of production grade additive manufacturing systems for 3D printed metals and 3D printed electronics is on an expansion drive with yet another signed distribution agreement with Emona Instruments Pty. Ltd for expanding sales of its solutions into Australia and New Zealand. In the past two months, Optomec has partnered with industrial 3D printing enabler Dragonfly to expand the reach of their aerosol jet technology into Italy followed by another partnership with additive manufacturing provider DETEKT Technologies Inc. to handle sales in China and Taiwan. With this new partnership, Emona will help further develop Optomec’s market in the two countries, distributing Optomec LENS Systems for 3D Printed Metals and Aerosol Jet Systems for 3D Printed Electronics. Emona is the leading supplier of additive manufacturing systems and engineering teaching equipment in Australia and New Zealand.

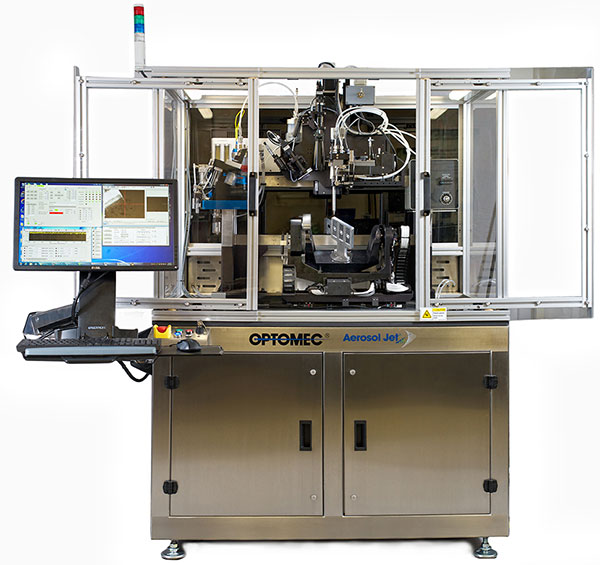

Optomec Aerosol Jet printers provide high-resolution 3D printing capabilities required to manufacture smaller, lighter-weight, high-performance devices used in industries such as aerospace, defense, consumer electronics and the Internet of Things (IoT). Aerosol Jet technology, which is scalable for high volume production applications, uses a patented process of aerodynamic focusing to precisely print electronic circuitry and functional components in dimensions ranging from as small as 10 microns to as large as several millimeters in a single pass.

LENS MR-7 specially configured for the rapid alloy development, functional prototyping and medium size part repair applications.

Optomec LENS printers use the energy from a high-power laser to build up structures one layer at a time directly from powdered metals. The LENS process can completely build new metal parts or add material to existing metal components for repair and hybrid manufacturing applications. LENS technology is available in standalone system configurations or as a modular print engine for integration with existing CNC automation platforms and robots.

“With Optomec ‘s established track record in Australia including users such as CSIRO’s Lab22, Swinburne University of Technology, Deakin University, UNSW, and University of Queensland, we look forward to the Emona /Optomec partnership further building on this success and reinforcing our position as the leaders in additive manufacturing in the region”, said Mark Breznik, Managing Director at Emona Instruments.

“We are very excited about our partnership with Emona to expand sales of Optomec products in Australia and New Zealand”, said Michael Kardos, Optomec Vice President of World Wide Sales. Emona has a 35-year track record of training engineers on new technologies and tools which will play a key role in developing the market in the region.