Germany-based 3D printer manufacturer One Click Metal has launched its latest laser powder bed fusion 3D printer.

The new MPRINT+, based on the previously released MPRINT, is an accessibility-focused metal system built for industrial prototyping and low-volume series production applications. Primarily aimed at SMEs and educational institutions, it comes complete with a new 200W fiber laser and galvo scanner, reportedly providing higher productivity and improved precision over its predecessor.

Stefan Weber, CTO and Co-Founder of One Click Metal, states, “When introducing the fiber laser into our metal 3D printer, it was important to us that we retain the great advantages of the MPRINT, but at the same time additionally improve the existing modules of the new MPRINT+.”

Metal 3D printing with One Click Metal

Founded in 2019, One Click Metal set out with the goal of making industrial metal 3D printing accessible to the world. As well as the MPRINT and MPRINT+ 3D printers, the company produces its own automated powder handling station, the MPURE, for use with its additive manufacturing systems.

MPURE is an essential unpacking chamber for powder removal and recycling, with an ultrasonic sieve to boot. With a frame measuring 1.1 x 1.9 x 0.79m, the MPURE is designed to sit right next to the MPRINT+ on the shop floor, providing users with access to a holistic end-to-end workflow without much of the technical hassle. The device also features a connection port to an external vacuum cleaner, maintaining a clean working environment devoid of any loose powder.

The new MPRINT+ 3D printer

The new MPRINT+ 3D printer features a cubic build volume measuring 150 x 150 x 150mm with an inert nitrogen gas outlet. As such, it’s compatible with a number of reactive metals such as aluminum, stainless steel, and tool steel – all of which are provided by One Click Metal.

The machine also offers an impressive focus diameter of 45 microns and a scan speed of up to 3000mm/s, with the company claiming a cost-per-component reduction of up to 40% when compared to competitors.

Much of the system’s accessibility comes from its easy-to-use supply cartridge system, where powdered feedstock is housed, reclaimed, and transferred in modular pods. The MPRINT+ comes with four cartridge slots, each of which can hold up to 11kg of material. This translates to a 250% oversupply relative to the build volume, resulting in fewer material changes and less downtime. Each of the cartridges is also fitted with a unique NFC tag, enabling users to check fill levels on the fly while ensuring incompatible metals are not accidentally mixed.

The cartridges integrate with the company’s MPURE unpacking station to automate much of the powder handling workflow. MPURE automatically depowders the part, screens the remaining powder for recyclability, and uses an ultrasonic sieve to integrate unused powder back into a reusable cartridge – all without the user having to contact any loose powder.

Technical specifications and pricing

Below are the technical specifications for the MPRINT+ 3D printer. The system, together with the MPURE powder handling station, is priced at around €100,000 ($118,000) and available to order now. Deliveries are scheduled to begin in Q2 2021.

| Build volume | 150 x 150 x 150mm |

| Material slots | 4 |

| Laser | 200W fiber laser |

| Focus diameter | 45 microns |

| Scan speed | 3000mm/s |

| Layer height | 20 – 80 microns |

| Dimensions | 1.9 x 1.1 x 0.79m |

| Weight | 450kg |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

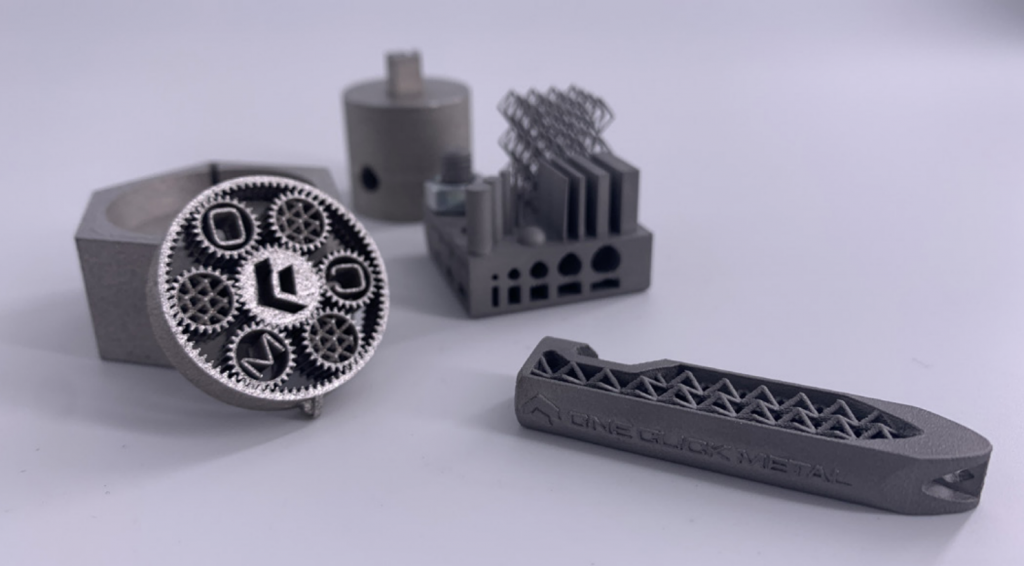

Featured image shows the MPRINT+ 3D printer and MPURE powder handling system. Image via One Click Metal.