NXT Factory, the California-based company behind Quantum Laser Sintering (QLS), has introduced its first fully automated polyamide additive manufacturing system, the QLS 350, at Rapid + TCT this week.

“We are thrilled to be able to bring to market the first-ever high-speed, high-temp, high-performance polymer system at comparable costs and performance of injection molding,” said Kuba Graczyk, Co-founder and CEO, at NXT Factory.

“Over the past three years, we have worked diligently to develop, test and perfect what we believe to be the only fully automated laser sintering production system featuring robotically guided exchangeable powder cart, integrated thermal management, and multiple sensors. Our cloud-based production management system gives end users total control over their printing processes.”

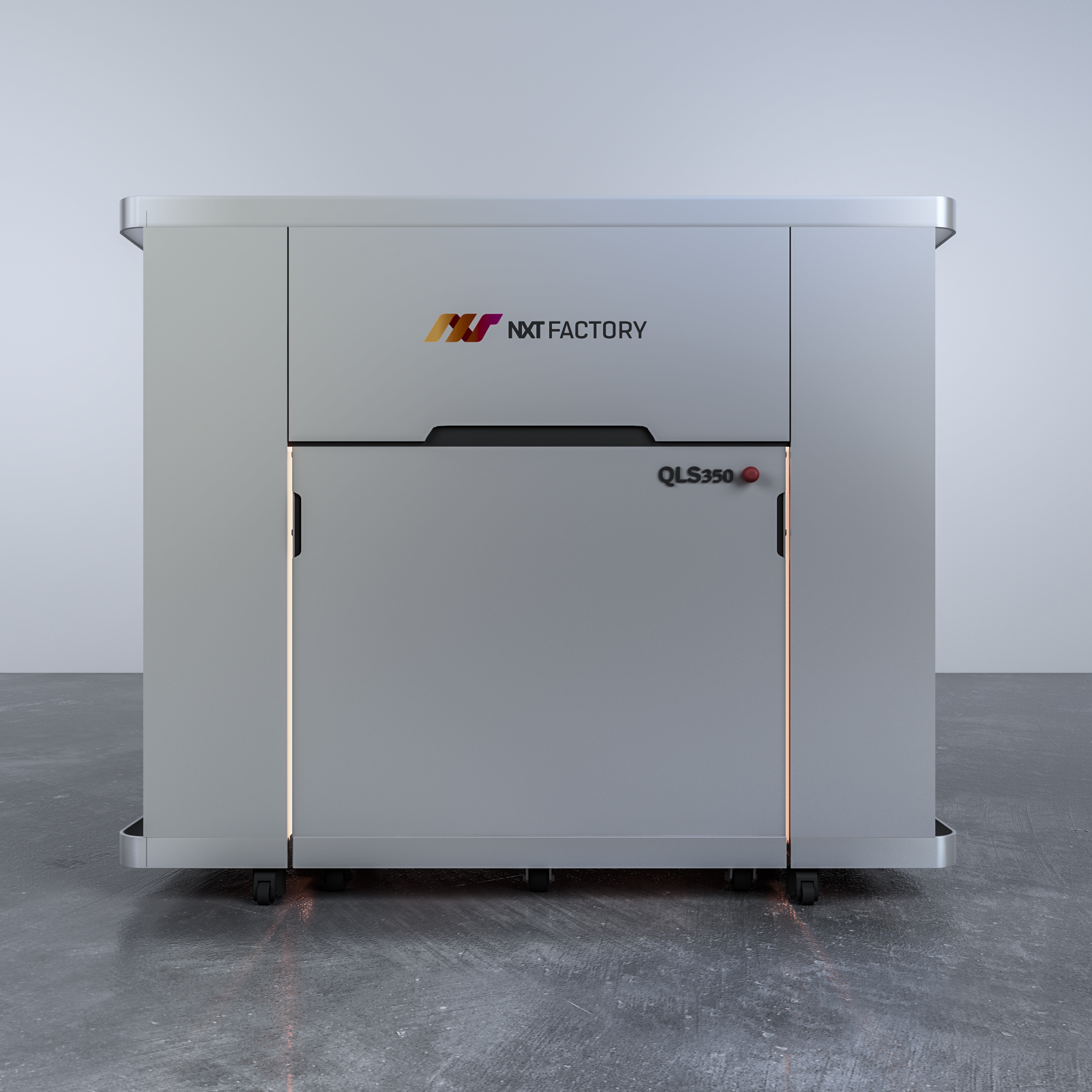

The QLS 350

According to the manufacturer, this new 3D printing system is said to feature the highest part throughput in its class. This machine converts a single laser into several million micro-lasers, without power degradation to replace traditional injection molding of plastic parts.

The QLS 350 reportedly maintains a printing speed up to 4X the print speed of comparable laser sintering technologies and is equal to multi-jet fusion 3D printers. This is attributed to the proprietary beam delivery system and the systems overall autonomous powder management.

Moreover, NXT Factory has integrated a removable robotically guided print chamber into the QLS 305 which enables autonomous cooldown and depowering, contributing to its 24/7 production capabilities. Avi Reichental, Co-Founder and Executive Chairman, at NXT Factory, added:

“We have been privileged to work with leading automotive suppliers to successfully validate our QLS 350 cost-effectiveness and demonstrate how ownership of this unique system can increase productivity, expand margins and make low-to-medium size production runs of 8,000 to 12,000 parts per run more profitable.”

Tomasz Cieszyński, Co-Founder and CTO, at NXT Factory, continued, “At the heart of our technology is our proprietary beam delivery integration with deep-learning algorithms that make real-time predictive and prescriptive choices to enable intelligent high-speed printing and real-time quality monitoring layer by layer.”

Technical Specifications

| Technical Specifications | |

| Printing Technology | QLS |

| Dimensions (Closed) | 200 x 140 x 200cm |

| Building Volume | 350x350x400mm |

| Weight | 750kg |

| Power Requirements | 26 kWatt |

| Operating Temperature | +5°C/+25°C |

| Interface | Web Dashboard |

| Laser type | 4x100W CO2 |

| Material delivery system | Autonomous Removable printing cart |

| Additional equipment | Powder handling and refreshing station |

| Z.Resolution | 50-200 microns |

| Printing Speed | 4200 ccm per hour |

Following the introduction of the QLS 350, NXT Factory has also announced of its preferred materials partner program with qualified third-party suppliers. This program is designed to open the QLS 350 platform to the best material suppliers.

The QLS 350 can be seen at booth #2117. Presently, those interested can preorder the QLS 350 system at an undisclosed price. Shipments will begin during the second half of 2019.

Remember to vote for the 2019 3D Printing Industry Awards.

Can’t make it to Detroit and don’t want to miss any news from RAPID? Subscribe to our 3D Printing Industry newsletter and follow us Facebook and Twitter for full coverage of RAPID + TCT.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows a bird’s eye view of QLS 350 systems. Image via NXT Factory.