3D bioprinting start-up Allegro 3D has been awarded nearly $1 million by the National Science Foundation (NSF) to fund the R&D of a novel high-throughput cell-printing platform.

Through a Small Business Innovation Research (SBIR) project, which is now in its second phase, Allegro 3D aims to develop a new printer that’s capable of rapidly creating in-vitro tissue testing models. The company anticipates that its upcoming system will enable pharma-firms to expedite their current workflows, and produce highly-accurate models for therapeutic and biomedical research applications.

“We are grateful for NSF’s continuous support from Phase I to Phase II,” said Dr. Wei Zhu, CEO of Allegro 3D. “With the newly-awarded Phase II grant from NSF, we aim to develop a next-generation 3D bioprinter, with higher throughput for fabricating tissue models at the industrial scale, to advance drug discovery and assay development.”

“Allegro 3D strives to provide transformative biofabrication solutions for the life science industry to advance human healthcare.”

A scalable bioprinting approach

Founded in 2018 by the University of California San Diego’s (UCSD’s) Zhu and Shaochen Chen, Allegro 3D specializes in the integration of stem cell biology into bioprinting systems and materials. The firm says that it’s working on technologies which will “revolutionize” the bioprinting sector, by allowing for the large-volume production of biomedical devices, cell matrices and ultimately cell-culturing human tissues.

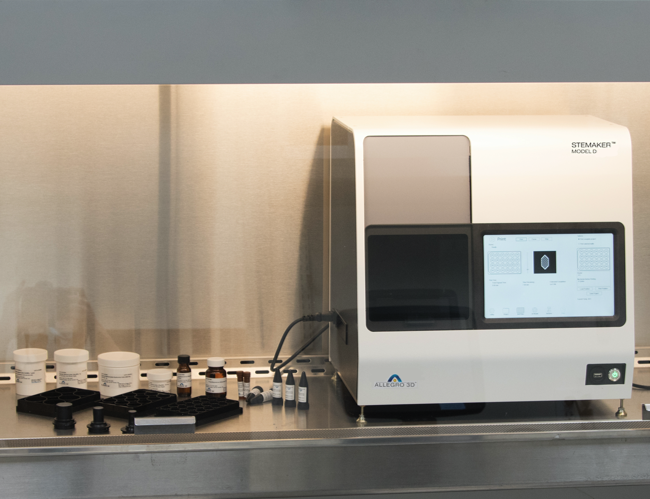

Allegro 3D recently announced the launch of its inaugural system, named the ‘Stemaker Model D.’ Marketed as the first-ever Digital Light Processing (DLP) bioprinter, the machine is designed to automate the direct in-well printing of 3D human tissues. Using a 405 nm blue light engine rather than extrusion, the printer is reportedly capable of creating scaffolds 1000 times faster and 10 times more accurately than current systems allow.

Measuring 454mm x 362mm x 441mm, the machine is also able to accommodate the automatic 3D printing of 6, 12, and 24-well plates, making it ideal for accelerating medical research. In the past, Allegro 3D’s technology has been deployed to help create stem cell treatments for spinal injuries, but in its latest SBIR program, the firm is now developing a next-gen system for cellular fabrication on a grander scale.

Allegro’s NSF-backed machine

Allegro 3D has been working on its upgraded machine since 2019, when it was first awarded SBIR Phase I funding of $299,281, to develop a novel high-throughput optical projection (hTOP) bioprinter. The project initially focused on the creation of human tissue liver models, which were designed to be used for preclinical drug screening and disease research.

Since then, the company has received a Phase II investment of $997,692 from the NSF, with a further $500,000 potentially available if it manages to sell its technology to a third-party. Using the additional funding, Allegro 3D aims to build an upgraded system, capable of producing physiologically-relevant tissues on an industrial scale, with a more diverse array of assay development applications.

Leveraging Allegro 3D’s existing Stemaker machine, users are currently able to deposit 3D tissues directly into commonly-used multiwell plates. Building on this feature, the firm’s upcoming printer is now being designed to enable drug screening directly within these wells, drastically simplifying the conventional workflows of pharmaceutical firms and biomedical researchers alike.

“NSF is proud to support the technology of the future,” added Andrea Belz, Director of the Division of Industrial Innovation and Partnerships at NSF. “With the support of our research funds, any deep technology start-up or small business can guide basic science into meaningful solutions that address tremendous needs.”

Ramping-up cellular production

3D bioprinting remains in a constant state of development, and a significant amount of research is being conducted into making the process ever more faster, scalable and accurate than before. Just last month, researchers at the Munich University of Applied Sciences developed a new ultra-high-precision approach, that’s capable of bioprinting at a single-cell resolution.

In a similar vein, scientists from the clinical firms Fluicell and Cellectricon have partnered with the Swedish Karolinska Institutet to 3D bioprint neural cells into complex patterns. The research could precede the creation of ultra-realistic brain tissues, that better mimic natural neural structures, and provide more accurate neurological disease models.

Elsewhere, when it comes to speed, a team based at the University at Buffalo may well have set a new bioprinting record, with their novel vat-SLA-based approach. Using a new ‘CLIP’ method, the scientists have been able to rapidly produce hand-shaped hydrogel structures in just 19 minutes, potentially making it a big step towards on-demand 3D printed organs.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Allegro 3D’s existing Stemaker Model D 3D bioprinter. Image via Allegro 3D.