How can 3D printing give you faster internet? Form-fitting health trackers for sneakers? Or even an invisibility cloak? Scientists in photonics (the study of light) have been working on projects touching these ideas for some time. At the base level, such products rely on the manipulation of light, through waveguides designed to channel/block specific wavelengths.

The challenge is, how do you design a guide for light that is typically invisible to the human eye?

New light-bending research described by a team at Northwestern University (NU), Illinois, may have the answer.

Based on the principle of inverse design – a concept that turns the traditional design process on its head – NU’s study crosses the boundaries of generative design, finite element analysis and machine learning.

“I feel like we’re really on the verge of something big,” says Koray Aydin, project lead and assistant professor of electrical engineering and computer science at NU.

“There’s a lot that needs to be done in the research part, but we’re going in the right direction.”

Inside out design

Instead of designing new sensors based on those that already exist, the NU team takes functional information about a desired product and feeds it into a computer. Working through powerful algorithms, design optimization programs, and 3D modeling, the function is finally sculpted into a digital shape – a shape otherwise unimaginable to the human brain.

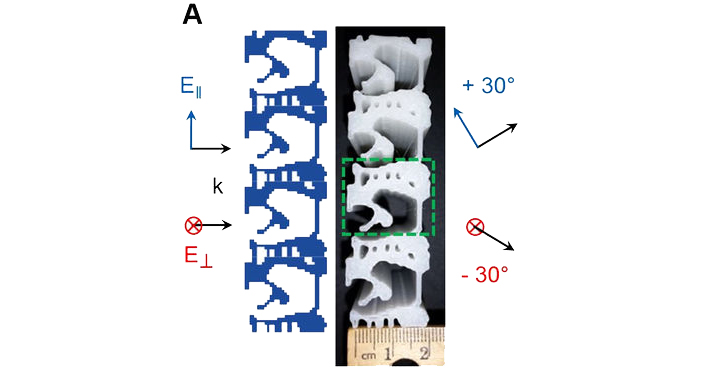

Seeing the first results of the inverse design process, Aydin said, “These were not known shapes, not intuitive shapes.” They resemble cross-sections of bone, or water spills – not the kind of shapes you’d traditionally associate with a lens.

The only way of making such impossible shapes is, of course, by 3D printing. “This is the heart of the study,” adds Aydin, “We’re the first to combine these two to make working devices.”

Beam splitting for 5G

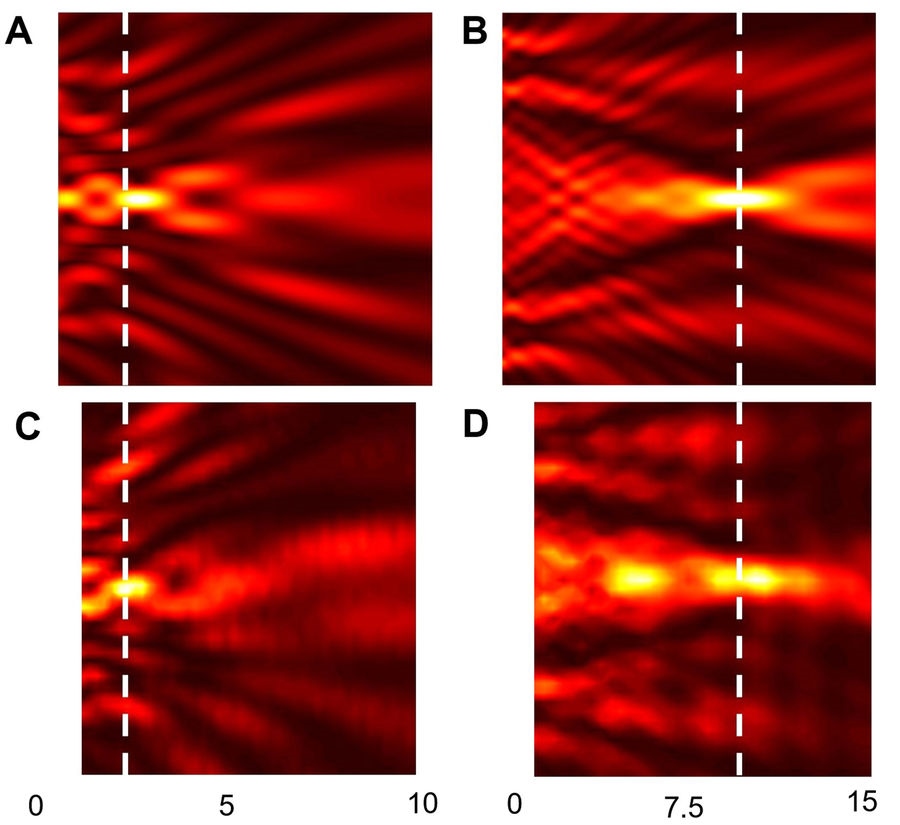

The wavy channels are generated by the system to either split, bend or focus light beams in a certain way, resulting in transmission of data signals that are used, for example, in 5G communications, or broadband internet.

Beam manipulating devices are made by Aydin and the team using an off-the-shelf FDM 3D printer ordered on Amazon.

In tests, the so-termed “metalenses” demonstrate, amongst other abilities, that they can produce an output of 38 GHz within the defined wave bands required for 5G communication (28, 38, and 60 GHz).

According to NU Professor Prem Kumar, “What we’ve achieved here is a new way of creating electromagnetic devices that achieve certain functions that conventionally seemed impossible to do.”

Full results of the study “Inverse-Designed Broadband All-Dielectric Electromagnetic Metadevices” is co-authored by F. Callewaert, V. Velev, P. Kumar, A. V. Sahakian and K. Aydin. It can be read online in the journal Scientific Reports.

For more research and 3D printing news subscribe to the free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Award winning research? Make your nominations in the 2018 3D Printing Industry Awards here.

Featured image shows a beam splitting glass cube. Photo via Light Machinery