A custom built 3D printer may enable wider use of metal additive manufacturing according to researchers at the National Institute of Standards and Technology (NIST).

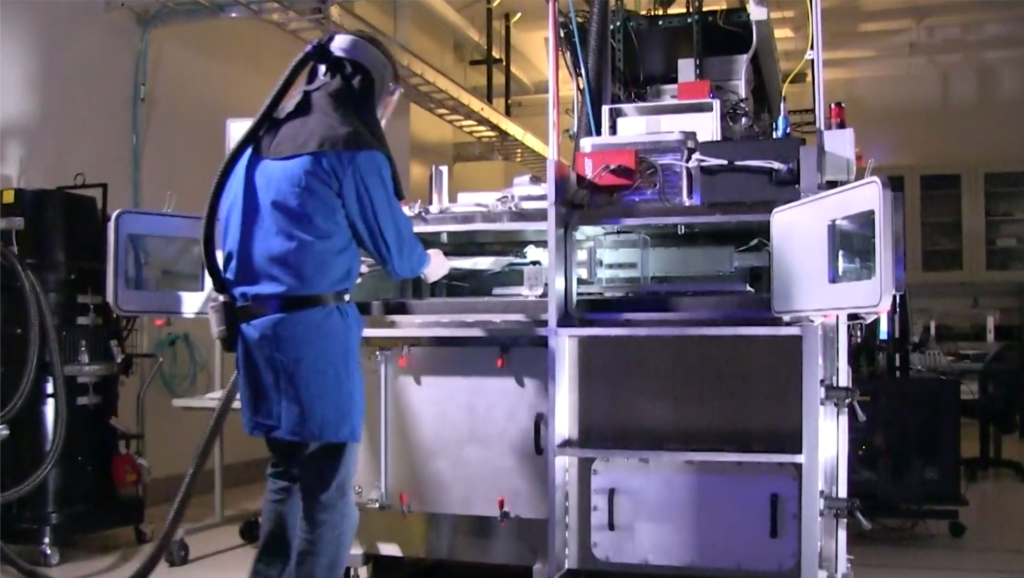

The Additive Manufacturing Metrology Testbed (AMMT) 3D printer was made by members of NIST’s Engineering Laboratory (EL) and Physical Measurement Laboratory (PML) and will be used to study 3D printing with metal.

In an earlier interview with 3D Printing Industry NIST’s Shawn Moylan explained one of the institute’s long-term goals as, “qualify as you go.”

It’s not just the part

To achieve this goal Moylan stressed the importance of understanding, “all of the changes that are going on with the material and the part and the process as we go from design to part. So in the end, it’s not just the part. It’s the part plus all of that additional information.”

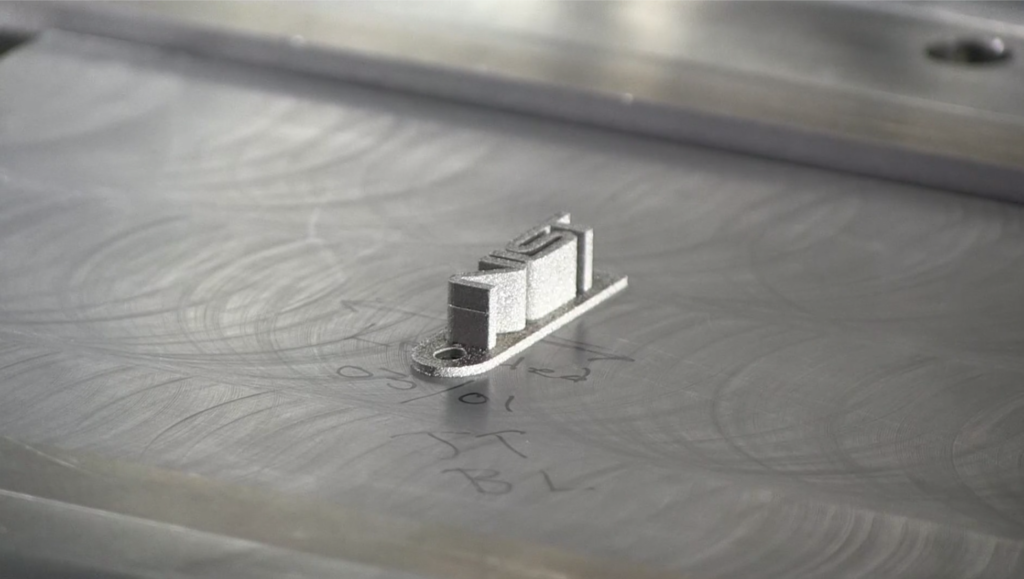

NIST has now given further details of how this work is progressing. The AMMT is a power bed fusion (PBF) additive manufacturing machine – approximately the size of a small car. The testbed is a functional metal 3D printer and can be used to test the suitability of new sensors and monitoring systems.

NIST’s Brandon Lane explains the need for the testbed, “Commercial systems are a little bit ‘black box. You can command a certain laser power and velocity, but you really don’t have control over every single microsecond of the process. With our system, we can control the speed and power of the laser at 100 kilohertz – that’s every 10 microseconds.”

Measuring the melt pool

The AMMT is designed to allow precise measurements to be taken of the melt pool. Currently the system is configured to measure brightness in the melt pool, with a focus on relative measurements. This is sufficient to measure fluctuations but a longer term goal is the ability to record absolute measurements and take the actual temperature of the melt pool.

To record this data a camera including a custom-designed achromatic lens is used. However the NIST scientists are developing a device they call the Temperature and Emittance of Melts, Powders, and Solids (TEMPS) sensor. “When the TEMPS system comes in, we’re going to get three times the magnification and expanded wavelength regime,” said Lane.

Further details of the NIST project are available here.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.