Car manufacturer Nissan has begun using 3D printing technology developed by BCN3D to bolster its automotive production lines in Spain.

It’s been revealed that the company’s Barcelona factory now features IDEX FFF technology, with parts such as tools, jigs, fixtures, and functional prototypes being 3D printed. Before now, Nissan outsourced all of its tooling to third-party suppliers that operated on traditional manufacturing processes such as CNC machining. While the part quality was indeed high, the firm faced long lead times and high costs, with simple metal tools sometimes costing around €400 apiece.

By bringing the design and fabrication process in-house, Nissan has reportedly slashed manufacturing times from a week to just one day, all while cutting costs by an average of 95%. Using BCN3D 3D printers, the company has produced more than 700 parts so far, some of which cost just €3.45. In fact, Nissan has been so impressed with its time and cost savings that it now intends to employ additive manufacturing at some of its other factories worldwide.

Carlos Rellán Martínez, a manager at Nissan Motor Ibérica Zona Franca, Barcelona, says, “Outsourcing tools to a mechanical supplier was 20 times more expensive than 3D printing the same parts, while the wait for tools went from a week down to one day. By introducing 3D printing, we have increased added value and generated low costs, without high delivery times. We have paid off the investment in the printers very quickly.”

A new print farm in Barcelona

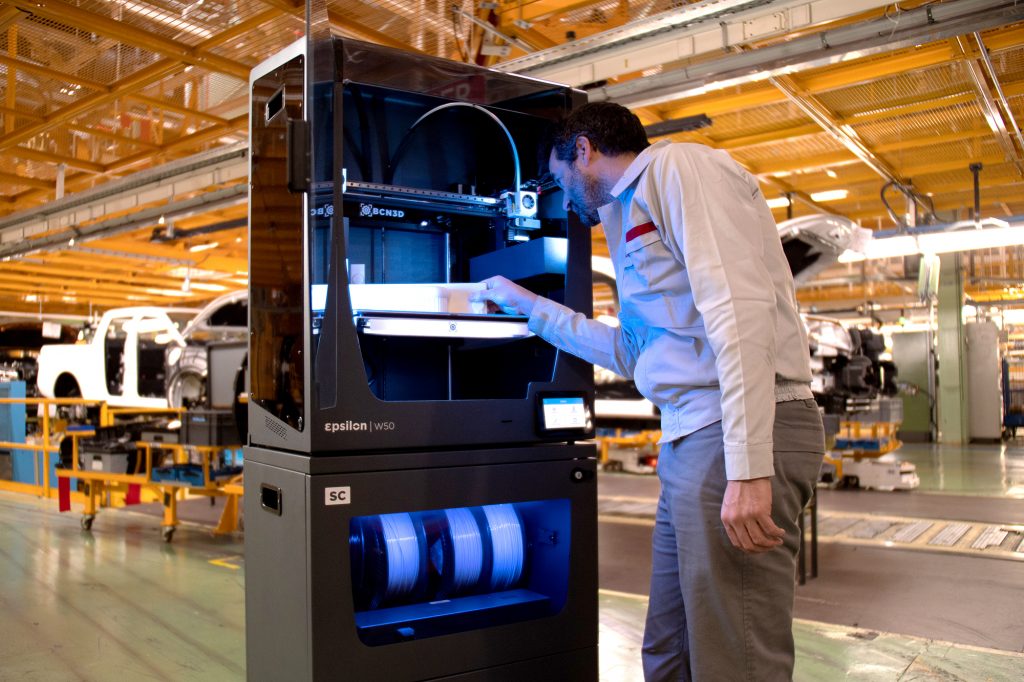

The Barcelona factory now has its own additive manufacturing laboratory, complete with four large-format BCN3D Epsilon W50 3D printers capable of running 24/7. The workbench systems feature a build volume measuring 420 x 300 x 400mm and an actively heated, enclosed chamber. Since the machines all offer IDEX setups, Nissan is able to print two identical parts simultaneously, doubling the print farm’s throughput.

Additionally, the company is also one of the first to use BCN3D’s new Smart Cabinet add-on, a humidity control device for filament storage. As well as preserving material printability, the device also provides an uninterruptible power supply to protect against blackouts.

Martínez adds, “The performance achieved in terms of reliability has been excellent. Our printer runs nearly 24 hours a day and every year we’re printing around 100 different jigs and tools for specific use in our processes.”

3D printing automotive tooling

The parts being 3D printed by Nissan include a tool to fix a windshield centering gauge, which is produced using TPU filament. With a print time of 14 hours, the tool cost the company just €8. Engineers at the additive manufacturing lab also 3D printed a jig to position the model name on the vehicle and a lower drill positioning tool, both of which were 3D printed in ABS in under a day.

Eric Pallarés, CTO at BCN3D, concludes, “The automotive industry is probably the best example of scaling up a complex product with the demands of meeting highest quality standards. It’s fascinating to see how the assembly process of a car – where many individual parts are put together in an assembly line – relies on FFF printed parts at virtually every stage.”

Nissan certainly isn’t the first manufacturer to adopt 3D printing for the production line, as automotive tooling is a prime application of the technology. Manufacturing service provider FreeFORM Technologies recently used binder jet 3D printing from ExOne to produce its own lightweight automotive tooling. Specifically, the company 3D printed a complex end-of-arm stainless steel component designed to be integrated with a six-axis FANUC robot as part of an automated part inspection system.

Elsewhere, in Germany, car manufacturer Audi recently began to use fully additively manufactured hot form tooling at its Metal 3D Printing Centre in Ingolstadt. By doubling down on its use of EOS 3D printers, Audi is now able to produce twelve different segments of four hot forming tools at the facility, which are later used to assemble car models such as the A4 saloon.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a BCN3D Epsilon W50 3D printer at Nissan’s Barcelona factory. Photo via BCN3D.