Nikon Corporation, a Japanese multinational supplier of advanced optoelectronics and precision technologies, has acquired majority ownership of metal 3D printing service bureau Morf3D as part of its aim to drive the industrialization of digital manufacturing.

The value of the deal is undisclosed, however Morf3D’s specialisms in aerospace, space, and defense indicate Nikon’s increasing interest and investment in additive manufacturing applications in these areas.

“Morf3D has proven leadership in metal additive technology, a strong innovation pipeline and highly specialized aerospace manufacturing qualifications,” said Yuichi Shibazaki, Corporate Vice President and General Manager of Nikon’s Next Generation Project Division. “It also brings a team of experts accustomed to partnering with customers to achieve their unique requirements.

“This combination is well-aligned with Nikon’s vision for accelerating industrialization of AM through innovation, and we look forward to working together to deliver exciting next-generation AM solutions to customers globally.”

Driving the industrialization of digital manufacturing

Since its inception in 1917, Nikon has been at the forefront of the global optical technology market, offering a wide range of products and technologies spanning digital cameras and binoculars, industrial precision equipment and semiconductor lithography systems, and microscopes and measuring instruments.

The company established its Next Generation Project Division in July 2019 with the aim of promoting new growth businesses such as materials processing technologies in order to drive forward digital manufacturing.

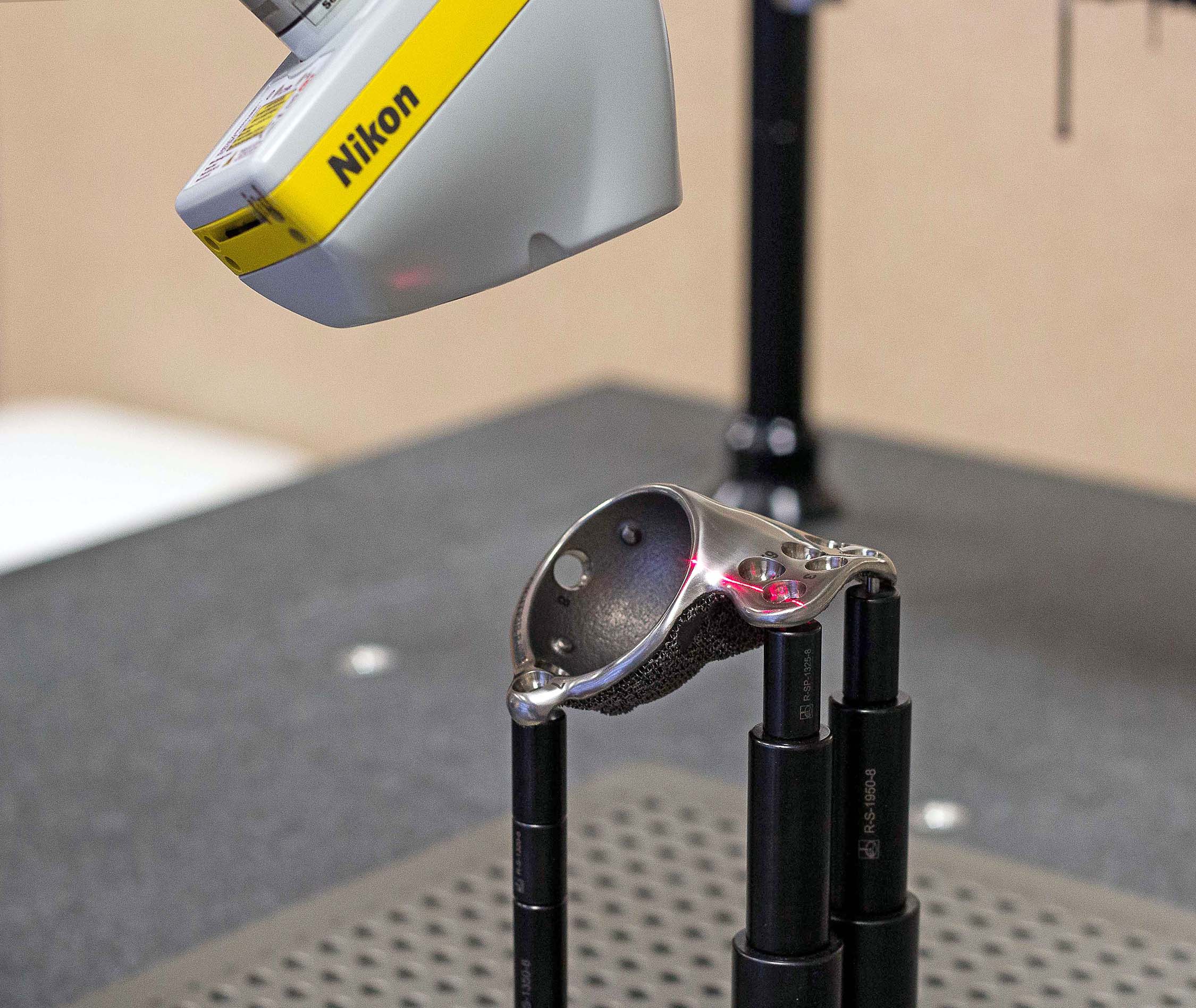

Nikon’s involvement in 3D printing, however, can be traced back several years before this when the company enlarged its portfolio with optical 3D measuring instruments after acquiring Metris in 2009. The firm went on to partner with industrial 3D scanning and modelling company 3D Engineering Solutions in 2014 to create a new generation of metrology grade industrial CT scanners capable of converting scans into 3D models and CAD files.

Since then, Nikon’s 3D scanning systems have been used in the qualification of 3D printed hip implants from bespoke patient-care provider Orthic Balto, and in 2019 the firm partnered with 3D printing service provider Materialise to gain further insight into the 3D printing build process, supported by Materialise software and Control Platform.

Morf3D additive manufacturing

Specializing in metal 3D printing, Morf3D offers services in engineering and manufacturing that encompass design expertise, printing, finishing, examination, certification, and data analysis. The company has held an alliance with inspection software specialist Sigma Labs since 2017 to add weight to its quality assurance offering.

Initially founded in 2015, Morf3D received financial support from Boeing HorizonX Ventures, an investment arm of the Boeing aerospace corporation, in 2018. The company received a second round of funding from HorizonX a year later in light of increased customer demand for Morf3D’s services.

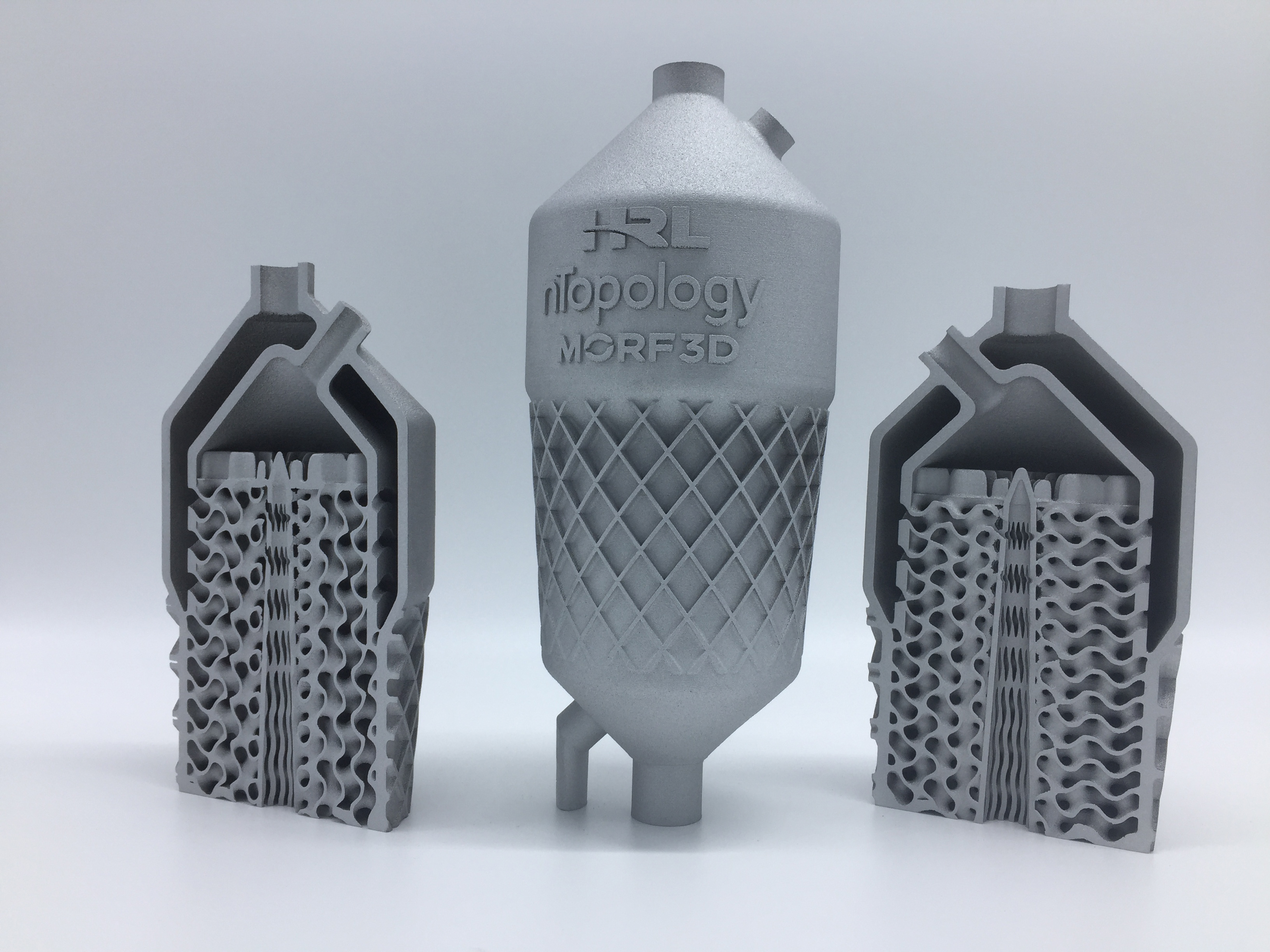

Morf3D has gone on to form several industry partnerships to advance metal 3D printing in recent years, having teamed up with California’s HRL Laboratories and software firm nTopology to explore advanced design and materials with what was deemed the “world’s strongest additive manufacturing aluminum” at the time, Aluminum 7A77. Morf3D was responsible for manufacturing a heat exchanger from 7A77 using one of its direct metal laser sintering (DMLS) 3D printing systems designed to outperform other additive aluminum alloys.

The company has also partnered with the Digital Industries Software division of industrial manufacturing firm Siemens to leverage its Xcelerator software’s design optimization and part qualification features to apply 3D printing in new product-enhancing ways.

Accelerating industrialization of AM

Nikon’s products have been used in applications ranging from advanced semiconductor manufacturing and mass production of television and smart device panels, to medical systems and satellites. The company’s latest move to acquire majority ownership of Morf3D looks set to further expand its portfolio into novel fields within optoelectronics and precision engineering through metal additive manufacturing.

Morf3D’s metal 3D printing technology enables complex design and manufacturing challenges to be solved through deploying its additive design and analytical tools, alongside its experience in additive manufacturing serial production. The company’s expertise in 3D printing services for the aerospace, space, and defense sectors opens up further novel applications for Nikon in these fields, in line with the intentions of its Next Generation Project Division.

“Nikon’s investment and cutting-edge technology accelerates Morf3D’s position as an innovation leader in advanced manufacturing for the aerospace, space, and defense markets,” said Ivan Madera, CEO at Morf3D. “Our unique partnership is well-positioned to bring forth the highest level of quality, service, and technological advancements that will drive the industrialization of additive manufacturing.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Morf3D’s R&D Innovation Center. Photo via Morf3D