3D printer OEM Nexa3D has announced the launch of its NexaX 2.0 software program, a comprehensive ‘file-to-part’ platform for use with the company’s NXE 400 resin 3D printers.

Developed in collaboration with engineering software company ParaMatters, NexaX 2.0 features both file slicing capabilities and full manufacturing execution system (MES) workflow functionality. As such, it covers every aspect of the pre-printing setup stage, and is designed to allow manufacturers to adopt additive manufacturing with reduced costs and time requirements.

Izhar Medalsy, CTO of Nexa3D, states, “With our NXE 400 3D printers completing entire jobs in 15- to 30-minute cycles, we quickly realized that file preparation and build set up are new sources of bottlenecks as these processes can take orders of magnitude longer than the entire print job. This problem is exactly what we set out to solve with NexaX 2.0.”

From file preparation to fleet management

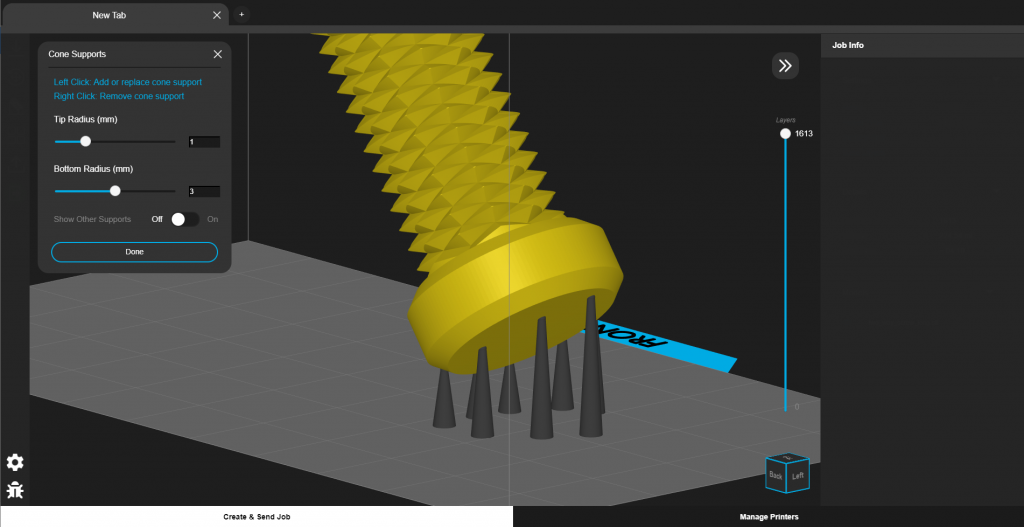

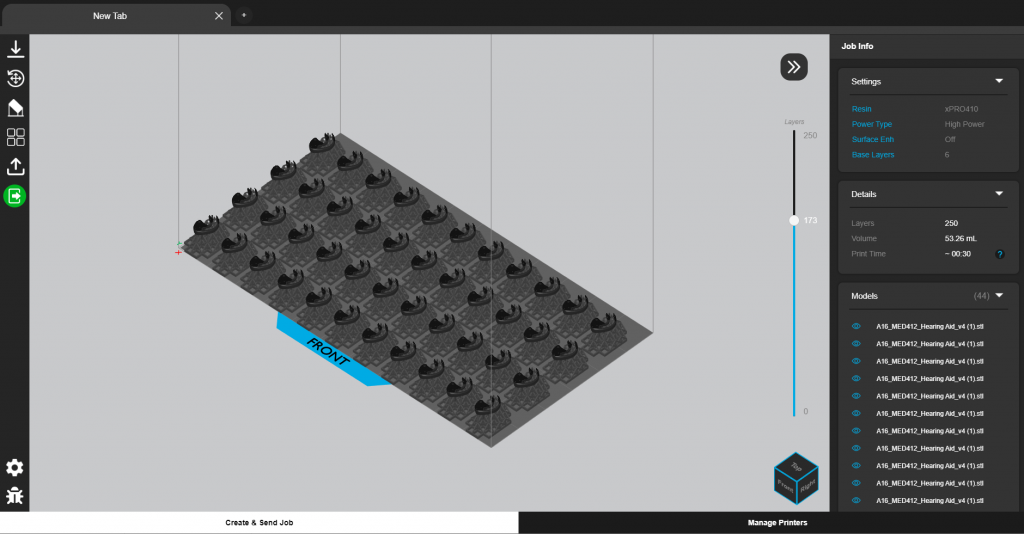

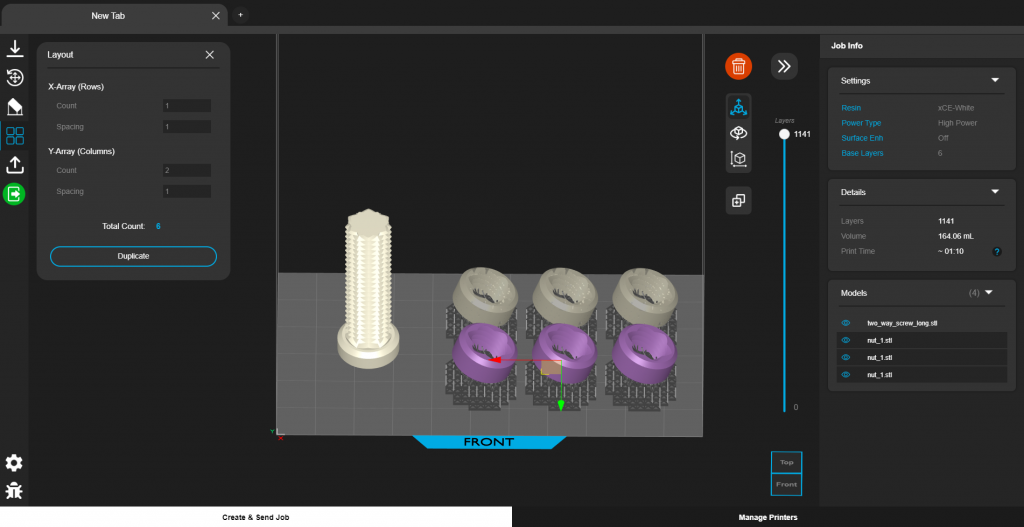

NexaX stems from the company’s productivity philosophy, and is intended to optimize polymer part production by consolidating support generation, build setup, and print management capabilities all in one place. The platform reportedly cuts part preparation times in half when compared to its competitors, and features the company’s own proprietary slicing algorithms. NexaX also provides a resin consumption estimation tool, remote fleet management actions, and even a live print view function for in-process monitoring.

Medalsy adds, “We are committed to advancing our digital manufacturing platform capabilities and this strategic collaboration with ParaMatters is a real force multiplier. We are very proud of the incredible platform Nexa3D’s software team developed in collaboration with ParaMatters, and thankful that all our beta users agree.”

Integration with other software tools

As a bonus, NexaX 2.0 is also intended to seamlessly integrate with other software tools. The platform’s APIs allow for lightweighting, automated print parameter optimization, generative design, part costing estimations, and even ROI calculators for the final printed products.

Furthermore, NexaX is compatible with the company’s Ximplify platform, an automated 3D printing cost analysis tool. By scanning through an extensive list of potential materials in minutes, Ximplify can recommend ideal candidates for a variety of 3D printing applications, as well as the best 3D printer for the job. Once it’s done, the program also generates an automatic report explaining its entire decision making process, which can be a great resource for newcomers to get to grips with industrial 3D printing.

Michael Bogomolny, CTO of ParaMatters, concludes, “At ParaMatters, we pride ourselves on developing Industry 4.0 intuitive design and manufacturing productivity tools that make it easy, fast and cost effective for designers and manufacturers to bring their new products to market. We are thrilled to collaborate with Nexa3D on bringing to market such a powerful platform that is truly a game changer for the AM industry and appreciate the confidence they have placed in us.”

Within the ever-more digitized world of manufacturing, MES programs like NexaX 2.0 are rife. Software provider Gravity Pull Systems recently launched its own comprehensive workflow optimization system with MES functionality for industrial 3D printing – Synoptik. The AI-based software is aimed at service bureaus and manufacturing companies serving a wide variety of industries such as aerospace, medical and automotive.

Elsewhere, software developer Authentise has previously announced a partnership with Addiguru, a developer of real-time process monitoring systems, to advance the Authentise Manufacturing Execution System (AMES). Together, the duo have since been working to integrate AI-based in-situ monitoring functionality into AMES, allowing for real time actions alongside the existing digitized workflow management capabilities.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows automated support generation with NexaX 2.0. Image via Nexa3D.