Nexa3D, a California-based SLA 3D printer manufacturer, has announced it is working with leading global chemical company Henkel to develop a line of co-branded photopolymer SLA resins, which will be distributed through Nexa3D’s global channels.

Through the newly established partnership, Nexa3D has now joined Henkel’s open platform of material partners. Both companies aim to leverage their respective expertise in SLA 3D printing technology and performance resins to create functional parts using Henkel’s materials on the NXE400 3D printer. Their first material, optimized for the NXE400, is an ABS 3D printing resin developed with Henkel’s Loctite material technology.

“Partnering with a great global powerhouse of the caliber of Henkel represents orders of magnitude of progress in our collective abilities to deliver additive manufacturing solutions that push the boundaries of what’s possible with 3D printing for manufacturing,” comments Avi Reichental, Co-founder and CEO of Nexa3D.

“We very much look forward to a long and prosperous relationship with Henkel making industrial-scale 3D printing a reality for manufacturers around the world.”

3D printing industry partnerships at Henkel

Founded in 1876, Henkel has grown to become a multinational chemical company active both in the consumer and industrial sector. It is responsible for developing global adhesive brands such as Sellotape and Loctite, and in 2016, the company entered the 3D printing materials market. Following this, the company also opened a 700 square meter multi-million Euro facility in Ireland to develop new advanced additive materials.

Since then, Henkel has continued to expand its partnerships and foothold within the 3D printing industry. This includes its partnership with Californian 3D printing startup Origin signed February 2019; the companies have since developed a new fire-resistant photopolymer, compatible with the Origin One 3D printer.

Additionally, Henkel has also launched its open materials platform for manufacturers of 3D printers, allowing companies to qualify Henkel’s materials with their different additive manufacturing technologies. Nexa3D joins the likes of German 3D printer manufacturer Rapid Shape on the platform, who is working with Henkel to develop novel 3D printing applications.

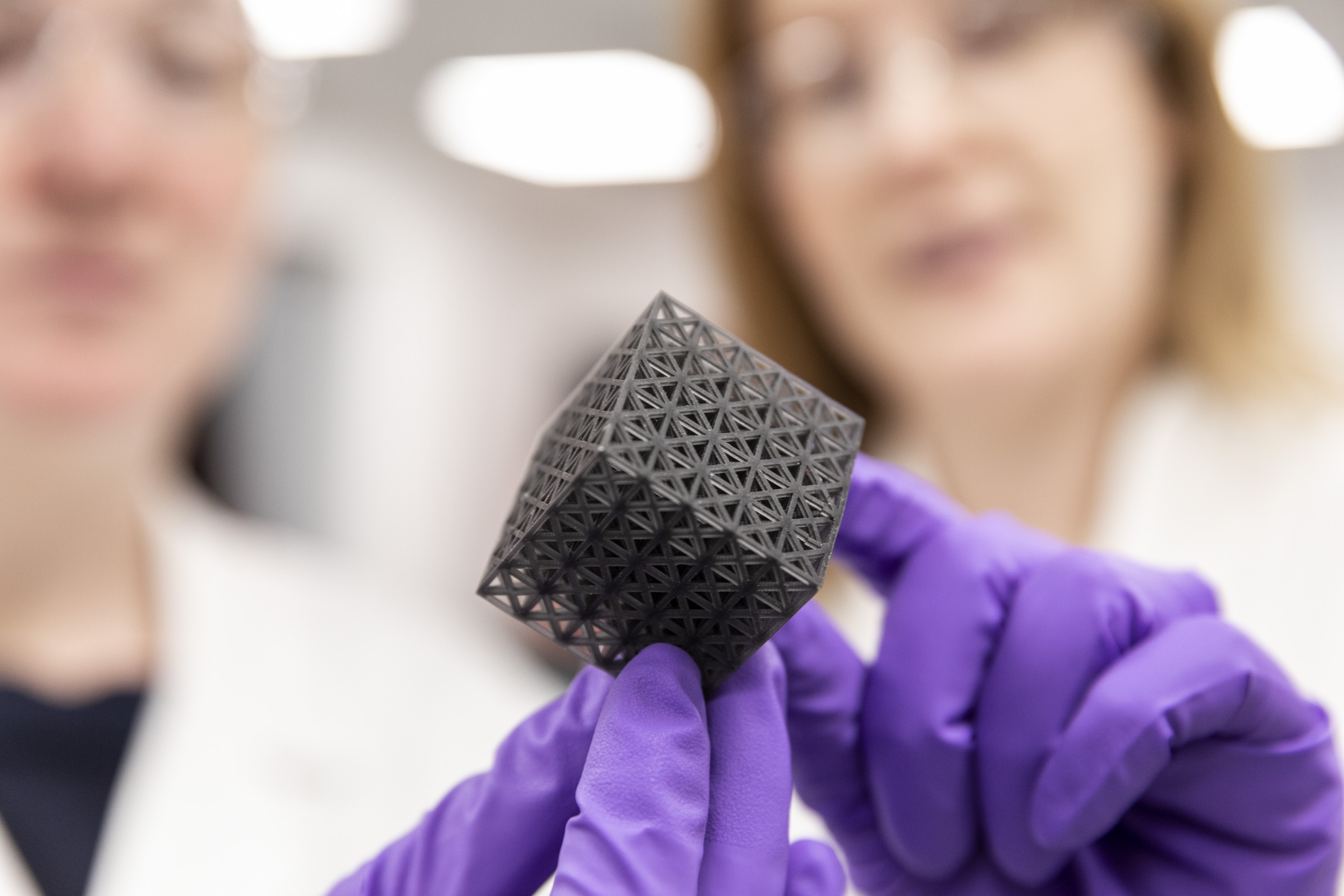

Nexa 3D sought to partner with Henkel due to its track record of developing a variety of materials that overcome the hurdles of conventional photopolymer resins used in 3D printing. As such, Nexa3D is now providing a new 3843-xABS Black material based on Henkel’s Loctite line of materials. 3843-xABS Black is designed to have high flexural and tensile physical properties, alongside high green strength and heat deflection temperature.

The material is intended for a wide variety of applications including mechanical assemblies for robotics and automation machinery, brackets, levers and arms for manufacturing stations, and transportation vehicles parts and assemblies.

Additionally, the two firms are planning to optimize Henkel’s portfolio of 3D printing resins to Nexa3D’s NXE4003D printer, in order to enable the creation of functional parts across a wider range of applications.

“We are pleased to partner with Nexa3D as our Loctite Industrial Product portfolio of PhotoPlastic and PhotoElastic materials are well suited for the high throughput of the NXE400 system,” explains Simon Mawson, Ph.D. Head of Additive Manufacturing at Henkel. “The Nexa 3D team has a proven track record of delivering robust solutions and I am confident our combined partnership will deliver the production tools, materials, and flexibility the industry demands.”

Nexa3D’s global reseller network

Nexa3D’s NXE400 SLA 3D printer was introduced at RAPID + TCT 2019. Describing the system, Reichental, who was appointed permanent CEO of Nexa3D in August 2019, stated that “This technology completely blows off the doors for what’s possible in terms of speed and size, and will unleash whole new levels of productivity and optionality for end-users.”

At the International Dental Show (IDS) 2019 in Cologne, Nexa3D also unveiled another new SLA system, the Varseo XL, developed specifically for the dental industry. The company worked alongside German dental device manufacturer BEGO to make the system compatible with BEGO’s full range of dental resins.

Additionally, Nexa3D has recently been expanding its global reseller network. Towards the end of 2019, it partnered with TWeatherford Inc. (TWI), an additive manufacturing solutions provider headquartered in Indiana, to sell its systems in the Midwest. This was preceded by partnerships with resellers in the UK, Germany, Austria, Switzerland and Russia as part of its European expansion, and with Brulé in Japan.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows mounting brackets 3D printing in 3843-xABS Black. Photo via Nexa3D.