Welcome to the latest edition of our 3D printing jobs and career moves update for the additive manufacturing sector. If you are looking for a new position in the industry, we keep our 3D Printing job board updated with the latest positions. You can easily apply to any of the posted jobs after creating a free profile. If you are just about to enter the sector, we offer a guide on how to get a job in the 3D printing industry.

The 3D Printing Industry jobs board is also free to use for employers to find 3D printing experts for their businesses.

Read on for updates on career moves at Fehrmann, SLM Solutions, Physna and new 3D printing facilities from Nanoscribe, Evonik and more.

Chief Operating Officer at MyMiniFactory, in London, UK

UK-based 3D printing content platform MyMiniFactory is hiring for a Chief Operation Officer (COO) to work at its London headquarters. Founded in 2013, the company aims to create a large ecosystem for 3D creatives and makers to exchange ideas in an open forum. Sustainability, purposefulness, and inclusivity are considered important values to MyMiniFactory, and candidates are expected to share this ethos. The company is now looking to accelerate the success of its online platform and is seeking an ambitious COO to coordinate this effort.

The ideal candidate will be enterprising and hungry for success, and the demanding role will reportedly require energy, skills, time, and courage. Day-to-day the position involves being the ‘right hand’ of the CEO, requiring superb execution with details, and being sharp when handling data. Successful candidates will also lead a team of developers, marketers, and designers in the fast-paced start-up.

Due to the demanding nature of the position, compensation will include shares in the business, in addition to the agreed salary. The full job description for the role of Chief Operating Officer at MyMiniFactory can be found here.

3D Printing Engineer at Rapid Manufacturing Technology (RMT), in Al Rai, Kuwait

Additive manufacturing services provider RMT is hiring a 3D printing engineer to work at its base in the Al Rai area of Kuwait. RMT’s platform offers a complete design-to-product process, providing evaluation and modeling tools for customers, in addition to instant quoting and ultimately 3D printing services. The responsibilities of the role include utilizing CAD Solidworks 3D 2020 to help clients design products to their satisfaction, in addition to any other duties that are assigned.

All projects must be followed through from the conceptual phase, right through to final assembly, with parts being optimized for manufacturing efficiency. Applicants must have a strong knowledge of 3D printing, and be able to work at the company’s facility in Kuwait. RMT does offer transportation to and from work, as well as other benefits such as 35 days’ annual leave and health insurance. The full job description for the role of 3D Printing Engineer at Rapid Manufacturing Technology can be found here.

Test Automation Engineer at Link3D, in New Jersey, U.S. (temporarily remote)

3D printing workflow software provider Link3D is recruiting for a Test Automation Engineer, which is temporarily remote, but will eventually be based in New Jersey. The company’s platform helps businesses to digitally transform their manufacturing strategies in order to better support their supply chains. Aiming to ensure the wider industrialization of 3D printing, Link3D works across a number of sectors ranging from aerospace and automotive to the medical industry.

As a Test Automation Engineer, candidates will need to be able to apply their creative problem-solving skills to design and write programs for automated testing on new or existing infrastructure. With the company continuing to grow, it is looking for experienced individuals that can scale applications to handle its increasing customer demand.

Among other duties, the role involves identifying areas of focus during testing, designing, and writing test automation scripts and investigating any problems encountered in the software. Therefore, understanding programming languages such as Java, Python, Javascript is deemed essential, as is experience in front-end (app and web) API automation.

Possessing a strong working knowledge and understanding of data models would also be of benefit, as would having a passion or interest in 3D printing technology. Interested candidates can find the full job description for the role of Test Automation Engineer at Link3D here.

The latest new facilities in additive manufacturing

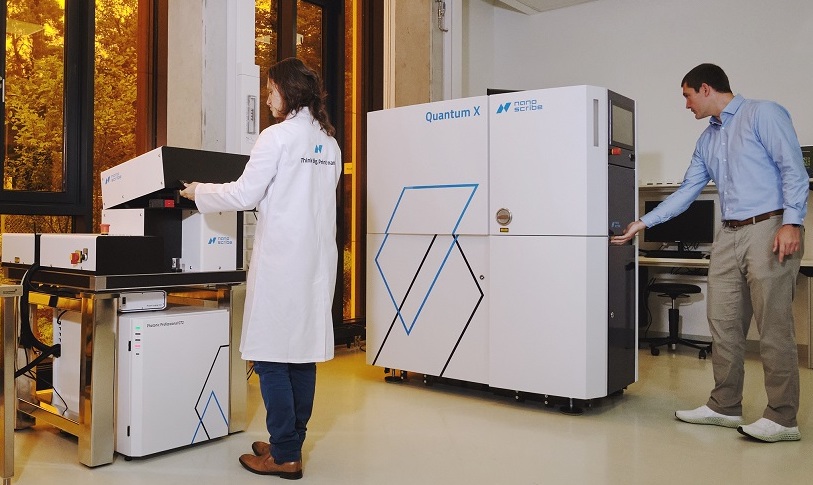

Nanoscribe, the German manufacturer of two-photon additive manufacturing systems, has opened a new Microfabrication Experience Center. Based at the company’s headquarters in Karlsruhe, the facility is designed to test and validate the feasibility of new applications, as well as to improve collaboration between Nanoscribe engineers. Large enough to host events for up to 100 people, the 270 square meter center will also invite visitors, who can experience all aspects of 3D Microfabrication.

The complex’s service portfolio ranges from individual product demonstrations, feasibility demonstrations, and training courses to expert workshops and user meetings. Many of the events are also offered online, and broadcast live from the center to complement the face-to-face events in Karlsruhe. In the Demolab, the heart of the facility, visitors can even participate in product demonstrations of the company’s Photonic Professional GT2 and maskless lithography Quantum X systems. These sessions are designed to provide a strong first impression of what’s possible with Nanoscribe’s 3D Microfabrication technology.

“We aim to inspire our customers and enable them to materialize their groundbreaking ideas and innovations with our 3D Microfabrication technology,” said Martin Hermatschweiler, CEO and co-founder of Nanoscribe. “The new Microfabrication Experience Center is therefore important to validate the suitability of our technology for customers’ projects and to intensify partnerships.”

SUNY New Paltz College goes for gold

The State University of New York at New Paltz (SUNY New Paltz) has achieved the coveted Leadership in Energy and Environmental Design (LEED) gold certification for its newly-opened $13.5 million Engineering Innovation Hub. Built to house the university’s mechanical engineering program, the facility has gained the award for featuring a very high level of sustainability and energy efficiency within its design and operation. The striking new building designed by Urbahn Architects also serves as a business incubator for technology startups in New York’s mid-Hudson Valley region.

Established by the U.S. Buildings Council (USGBC), LEED guidelines deliver a comprehensive framework for sustainable building design. Certification is achieved through a detailed application process, with an independent third-party reviewer assigning points to each project in seven distinct categories. Four levels of accreditation can be achieved including bronze, silver, gold, and platinum, making SUNY New Paltz’s award the second-highest possible.

“The Engineering Innovation Hub houses industry-leading equipment to support our students and faculty as well as the work of companies partnering with the College through 3D design and printing,” said President of SUNY New Paltz, Donald P. Christian. “We thank the Governor and his team for recognizing the value of this project, and our facilities staff and external partners for working hard to achieve this well-earned LEED Gold distinction.”

Evonik opens new 3D printing technology center

German industrial chemical corporation Evonik is further expanding its 3D printing business by opening a new technology center for 3D printing in Austin, Texas. The site will play a key role within the company’s development of new, ready-to-use materials for Powder Bed Fusion (PBF) systems. Featuring an application technology laboratory with 3D printing facilities, an R&D lab, and production rooms, the complex is essential to the company’s future plans.

The technology inherited by the company via its acquisition of Structured Polymers in January 2019, will feature prominently within the facility’s work, with the aim of expanding its existing product portfolio. In Structured Polymers’ patented technique, polymer granulate is processed into a fine powder. This method could enable Evonik to directly control particle sizes within a diameter range of 0.1 – 400 μm, while also yielding materials that offer enhanced properties for 3D printing.

“The new Technology Center continues the success story of Structured Polymers under the umbrella of Evonik,” said Thomas Große-Puppendahl, Head of the Additive Manufacturing Innovation Growth Field at Evonik. “We have now created the necessary framework to establish this advanced technology for the production of 3D printable polymer powders on the market.”

Career moves and new appointments within 3D printing

Cincinnati-based 3D modeling software startup Physna has announced key appointments to its executive team and board of directors. Firstly, Dennis DeMeyere has been made Chief Technology Officer (CTO) of the company. He joins from Alphabet, where he was a Technical Director in Google Cloud’s Office of the CTO. Mark Kvamme meanwhile, joins the Physna board of directors, bringing decades of experience from Silicon Valley businesses such as investment firm Drive Capital and Apple.

Having invested in the company during his previous role, Kvamme has said that Physnat could become “the Google of the 3D world.” Finally, Jason Warner has also been appointed to the board of directors. Warner is the CTO of GitHub, where he leads the software company’s product, engineering, security, and support teams. Prior to joining GitHub, Warner was VP of Engineering at Heroku, a cloud Platform as a Service (PaaS), allowing developers to deploy and manage applications at scale

“Great things happen when you have world-leading talent solving massive, fundamental problems,” said Paul Powers, Co-founder, and CEO of Physna. “Dennis, Mark and Jason believe in Physna’s ability to transform the way we search, create, share and work with 3D data. They’re the perfect match for Physna’s vision, ambition and technology, and their combined expertise will greatly add to our momentum and success.”

Fehrmann appoints Chief Digital Officer

The producer of performance alloys for 3D printing Fehrmann, has made Dr. Achim Tappe its new Chief Digital Officer (CDO). In the newly-created role, Tappe is responsible for supporting material development for metal additive manufacturing using machine learning/AI and digital transformation tools. Having previously worked for NASA and The Harvard-Smithsonian Center for Astrophysics, he now intends to “revolutionize” the development process for new materials.

“We want to develop sustainable materials in conjunction with 3D printing,” stated Fehrmann. “There’s still a lot of work to be done. Because the number of parameter combinations is very large and the existing data is very diverse, we are relying on Dr. Tappe’s know-how in the areas of AI and machine learning.”

SLM Solutions hires Director of Marketing

Finally, German metal 3D printer manufacturer SLM Solutions has hired Emily DeSimone as its new Director of Marketing for the Americas. Announced via Linkedin, DeSimone joins from Carbon3D, having also previously worked as an ambassador for Women in 3D Printing.

“What an opportunity to continue my journey in the additive manufacturing industry, but now with the ability to expand my knowledge outside of polymeric materials,” she said. “It was a tough decision to leave the Carbon family but I look forward to the expanded responsibilities to lead a team. ‘I know you have the ‘metal’ for this!’ (so says Joseph DeSimone, Co-founder of Carbon, with the pun intended!). Yes, I do, at SLM, let’s do this!”

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D Printing Industry Job Board.