Welcome to the latest edition of our 3D printing jobs and career moves update for the additive manufacturing sector. If you are looking for a new position in the industry, we keep our 3D Printing job board updated with the latest positions.

You can easily apply to any of the posted jobs after creating a free profile. If you are just about to enter the sector, we offer a guide on how to get a job in the 3D printing industry.

The 3D Printing Industry jobs board is also free to use for employers to find 3D printing experts for their businesses.

Read on for jobs at CAES and the US Army, moves at 3D Systems, Freemelt, PostProcess, Evolve Additive Solutions, Nano Dimension and SLM Solutions, and facility news from Sedaxis Advanced Materials, Boss Products, Stryker, Anisoprint, Feritech Global and more.

Senior Manufacturing Engineer, Additive Manufacturing at CAES

Cobham Advanced Electronic Solutions (CAES) is hiring for a Senior Manufacturing Engineer to work at its facility in Exeter, New Hampshire. Reporting to Senior Engineering Management, the role will see the successful candidate design, adapt and build parts using cutting-edge 3D printing technologies. As such, applicants will need a strong understanding of design for additive manufacturing (DfAM).

As well as a working knowledge of multiple technologies across LPBF, FDM, SLA and SLS, prospective CAES engineers have to be capable of supporting sales, by interfacing with internal and external stakeholders. The company is also seeking to recruit someone with five years’ experience in new product development, a background in 3D printing and at least a Bachelor’s Degree in Engineering.

More information about the role of Senior Manufacturing Engineer, Additive Manufacturing at CAES can be found via the 3D Printing Industry jobs site.

US Army General teases 3D printing Spec Ops roles

Jonathan Braga, a Lieutenant General in the US Army, says its Special Operations Forces (SOFs) are considering introducing brand new technology-focused roles and unit structures. Speaking at an Association of the US Army event last month, Braga explained that the war in Ukraine is making it clear that changes need to be made, if the US is to become ready for any future “large-scale combat operations.”

In particular, the Korea veteran highlighted how there isn’t currently an SOF career pathway for those skilled at deploying advanced technologies like 3D printing, AI or coding. While any new roles would require approval by the US Army, Braga revealed that he’s considering recommending the introduction of a warrant officer field, in which engineers can specialize in technology on the modern battlefield.

“We have some amazing individuals who are building drones from scratch…programming drones, creating backdoors, 3D printing, learning Python on their own. These people already exist,” he said. “What we don’t have right now is a proper career field and pipeline for them to maintain that talent and reinforce that [technology in special operations] can still be a successful career [for them].”

Leadership changes at Freemelt, 3D Systems and more

In the first of several leadership shake-ups in this week’s update, Swedish 3D printer manufacturer Freemelt has made Daniel Gidlund its new CEO. From October 18, 2022, Gidlund is set to join the firm from Sandvik Mining & Rock Solutions, and replace current CEO Ulric Ljungblad, who will take up the role of CIO instead.

“Freemelt is entering into a new phase, with a stronger focus on industrialization, [and] we are in alignment with Ulric Ljungblad that it is appropriate to appoint a new CEO with extensive experience from leadership in advanced industrial operations,” explains Freemelt’s Board Chair Carl Palmstierna. “Daniel Gidlund is a fantastic candidate for this assignment, and we are very pleased to welcome him.”

At 3D Systems, the US 3D printer manufacturer has unveiled plans to appoint Michael Turner as its EVP and CFO. Effective August 29, 2022, Turner will leave his current role as CFO for Innovative Chemical Products, and replace interim-CFO Wayne Pensky. In his new position, Turner will lead the firm’s agenda on accounting, controllership, financial planning, tax, treasury and investor relations matters.

Automated post-processing systems developer PostProcess, meanwhile, has hired marketing veteran Melissa Hanson as its CMO. Having spent 8 years marketing in 3D printing, including stints at Stratasys, Nexa3D and Trimble, and 17 in market-driven strategy deployment, Hanson brings a wealth of experience to the role.

As PostProcess’ new CMO, Hanson will lead the firm’s global marketing and inside sales agendas. In practice, this will see the marketing guru become responsible for developing and executing strategies that accelerate PostProcess’ global reach and position, and play a key role in fostering commercial collaborations.

Over in Minnesota, STEP 3D printing technology developer Evolve Additive Solutions has recruited Jeff Blank as its new COO. Blank, who was most recently COO of NanoVox / Vadient Optics, has a diverse business background, in that he spent two decades delivering 2D printers at Tektronix and Xerox, before moving on to 3D Systems, to run their worldwide engineering and product delivery organization.

“I am very excited to join this team and be part of bringing this revolutionary technology to market,” said Blank, “EAS and STEP will bring high-precision true thermoplastic parts to production customers in ways unheard of up until now. I am looking forward to bringing my experiences in both 2D and 3D product development to the organization and accelerating our path to growth.”

In 3D printed electronics, Nano Dimension has announced the appointment of Dale Baker as President of its Nano Dimension – Americas division. Taking over from Sean Patterson, who is leaving to take up the role of COO at a PCB manufacturer, Baker will work under the firm’s Global President Zivi Nedivi to lead its US expansion, worldwide sales activities and mergers and acquisitions (M&A) growth strategy.

“Only a few years ago, Dale was working with me as COO, successfully turning around a US public specialty chemical company,” said Nedivi. “Through his extensive career at GE and later as a CEO of numerous large public and private companies, Dale has always been a leader. I am convinced that he will be a substantial-quality enhancer and will be a major driving force in our growth.”

“I wish Sean good luck and much success. In parallel, I am very excited that Dale has agreed to leave his previous CEO role and is now joining Nano Dimension.”

Lastly on the hiring front, metal 3D printer manufacturer SLM Solutions has made Charlie Grace its CCO and the latest member of its management board. Drawing on the experience he’s built up through working at Xerox, 3D Systems, ExOne and EFI, Grace will now oversee the firm’s commercial strategy, business development and marketing activities, while continuing to serve as its GM in North America.

The company has also appointed Gerhard Bierleutgeb COO. Since joining SLM Solutions in 2020, Bierleutgeb is said to have demonstrated that he’s capable of ensuring customer success as EVP of Global Services & Solutions. In his new role, it’s thought the experienced business leader will better be able to lend his operational insight to proceedings.

“It’s individuals like Charlie and Gerhard who help us grow as an organization and implement our strategy with vigor making SLM a key enabler of our customers’ successful transition to additive manufacturing,” said Sam O’Leary, CEO of SLM Solutions.

“On behalf of the entire Supervisory Board, I would like to extend my congratulations to Charlie on his new leadership role and wish Sam and Charlie all the best in guiding SLM into a successful future,” added Thomas Schweppe, Chairman of SLM Solutions’ Supervisory Board.

New AM facilities opened across the globe

Moving onto facility news now, Sedaxis Advanced Materials and the Vellore Institute of Technology (VIT) – Chennai have announced the opening of their joint VIT-SEDAXIS Centre of Excellence for Additive Manufacturing. Based at the VIT Chennai campus, the complex is said to offer the most affordable design, engineering, and manufacturing services in the region to students and SMEs alike.

While the center has already begun supporting doctoral research students from VIT Chennai in their research, it’s also seeking to work with other institutions like the Indian Institutes of Technology and Indian Institute of Science to really put its reportedly extensive portfolio of 3D printers, materials, software and post-processing units to the test.

Elsewhere, in another Nano Dimension update, the electronics 3D printing specialist has opened its first office and 3D printing lab in Australia. Working from its new Sydney base, the company’s five-strong team is set to focus on developing business opportunities down under, as well as providing better support to its existing Australian clientele.

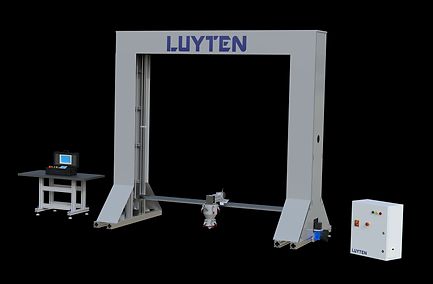

Also based in Australia, Boss Products has announced that it has transitioned from traditional production technologies, to Luyten 3D printing at its construction factory in Melbourne. By switching to additive manufacturing, the firm, which primarily focuses on supplying planter boxes and retaining walls to customers, has reportedly been able to slash its lead times and costs by up to 95%.

Over in Germany, meanwhile, continuous fiber 3D printer manufacturer Anisoprint has begun working with Jacobs University Bremen to establish a ‘research environment’ that’s centered around its technology. As part of the organizations’ collaboration, Anisoprint is set to relocate its R&D team to the university’s campus, and set up a lab packed with equipment there for material and process research.

The initiative is also expected to throw up opportunities for cross-learning, knowledge sharing and the exchange of best practices while giving the university’s students the chance to experiment with cutting-edge 3D printing technologies, and take part in training programs that could provide future career opportunities.

In Cork, Ireland, medical device manufacturer Stryker has opened a new 3D printing facility, which could ultimately create 600 jobs for the locals there. The company’s 156,000 sq. ft factory, its second such complex in the area, is expected to facilitate its core business in the production of devices and implants used in orthopedic surgeries, such as knee, shoulder, ankle and craniomaxillofacial procedures.

“Stryker has been innovating in additive manufacturing within the medtech industry for more than 20 years and opened its Anngrove facility in 2016,” said Martin Shanahan, CEO of IDA Ireland. “The expanded facility furthers the company’s four-decade commitment to Ireland and recognizes the strong ecosystem of universities, engineering talent and partners such as the IDA.”

Factories to expand with state funding

Finishing off this week with factory funding, the Israeli Finance Committee has awarded $6.1 million to the country’s Advanced Manufacturing Institute. This additional budget is set to be used to fund the rolling out of innovative technologies and advanced production methods in factories to improve their productivity.

In practice, the institute plans to offer consulting and implementation services in fields like robotics, automation, advanced information systems to industry partners. A first of its kind national demo center will also be launched in Karmiel in December 2022, which will focus on demonstrating how automation, robotics, manufacturing execution systems (MES), IoT, 3D printing and AI can benefit throughput.

UK-based engineering firm Feritech Global has also received a £1 million growth loan from the Cornwall and Isles of Scilly Investment Fund. Using the funding, the company plans to increase its stock of technical equipment, which is available for hire, as it has seen demand grow since its innovation center opened in April.

The new facility offers services that range from product design right through to fabrication, machining and 3D printing. According to Feritech Global’s MD Rob Ferris, the complex has “given it the space to grow as a business,” by expanding its services, and “enabling it to win important new contracts” from customers.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D Printing Industry Jobs Board. Image via 3D Printing Industry.