Researchers at the University of Sheffield have developed 3D printed antennas that can be manufactured faster and more cheaply than current 5G and 6G aerials.

During testing, the team’s millimetre wave (mmWave) devices are said to have demonstrated a radio frequency (RF) performance akin to that of conventionally-produced antennas. In future, it’s thought the aerials could help accelerate the roll-out of 5G and 6G infrastructure, both in the UK, and isolated areas abroad.

“This 3D printed design could be a game changer for the telecommunications industry,” says Eddie Ball, a Reader in Radio Frequency Engineering at the University of Sheffield. “The design could be used to produce antennas on a much larger scale and therefore have the capability to cover more areas and bring the fastest mobile networks to parts of the world that have not yet had access.”

“[3D printing] enables us to prototype and produce antennas for 5G and 6G networks at a far lower cost and much quicker than the current manufacturing techniques.”

An mmWave antenna overhaul?

According to the Sheffield-based team, manufacturing the antennas currently used to build telecom networks is often a slow, costly process. Given the pace at which the technology behind them is evolving, the researchers therefore argue that such manufacturing techniques “hinder innovation,” as they delay prototyping and the building of new infrastructure.

To get around this roadblock, the engineers have come up with a new design which can be affordably churned out at a much faster rate, without compromising on end performance. The antenna itself was developed at the UK Research and Innovation (UKRI) National mmWave Measurement Lab, a cutting-edge British R&D facility.

Also located in Sheffield, the complex was set up to allow industry and academics to test and measure antennas, circuit-on-wafer devices, and other radio frequency systems. Made up of three key pieces of equipment worth £2 million: an NSI-MI Antenna Measurement System, a Keysight four-port VNA, and MPI TS150-THz wafer probe stations, the lab can be rejigged to meet researchers’ exact project needs.

Ultimately, the facility makes it possible to measure antenna performance from 10 GHz up to a range of 110GHz, something the team from Sheffield found “invaluable” in testing. During these experiments, the engineers developed an antenna 3D printing method around silver nanoparticles, which are understood to have ideal properties for RF applications, and have been tested at up to 48 GHz frequencies.

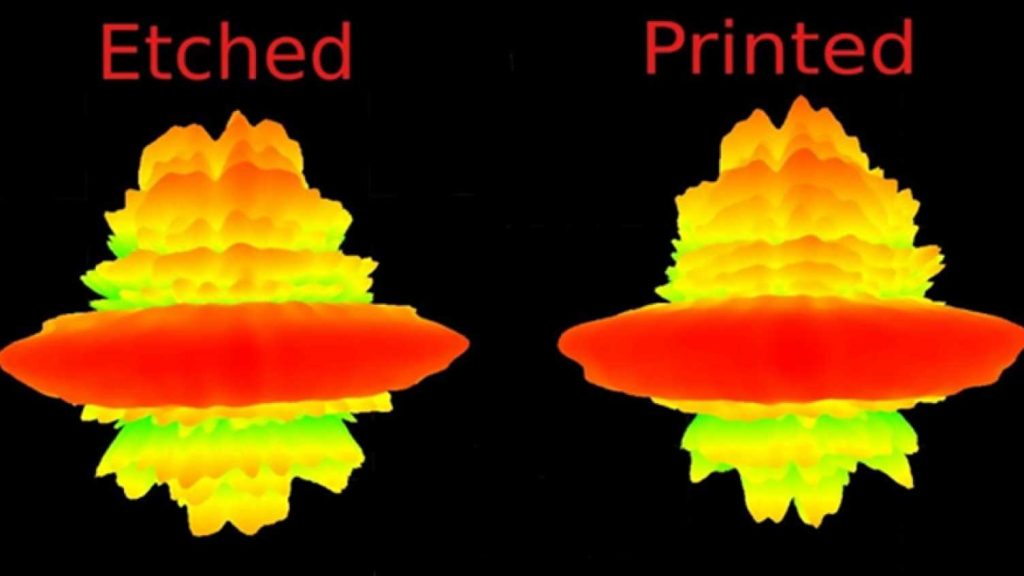

Having conducted range and frequency experiments at the lab, the team went on to map their results via a set of 3D surface plots (pictured below) that compared their device to a conventional aerial. As it turned out, the differences between the antennas’ gain and time domain responses, which indicated the direction and strength of the signal they were able to transmit, were ‘almost indistinguishable.’

Given that the researchers’ 3D printing technique enabled functional devices to be created in as little as a few hours for just a few pounds, they say it could offer an attractive low-cost alternative to current aerial production methods. For those living in remote areas, the team also suggest that their 3D printed antennas may one day help bring stronger mobile phone signals and faster internet connections.

The growing frequency of AM antennas

With wireless connectivity now more central to our lives than ever before, the clamour for new, faster ways of transmitting cell signals continues to grow. In recent years, this has led researchers to toy with 3D printing to achieve this, and another UK team has previously developed 3D printed 5G MIMO antennas of their own.

Elsewhere, engineers at the University of Delaware have managed to create signal-bending 3D printed Luneburg lenses, that can connect electronics, sensors or mobile phones. That said, the team is now said to be working with the US Army, to explore their devices’ defense-related robotics and civilian aerospace applications.

In the commercial sphere, Optomec has also come up with a way of using 3D printing to boost 5G antenna signals. Specifically, the firm has developed a semiconductor solution that involves using 3D printing to integrate millimeter-wave circuits into cell signal emitters, in a way that provides nearby users with an improved cell connection.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

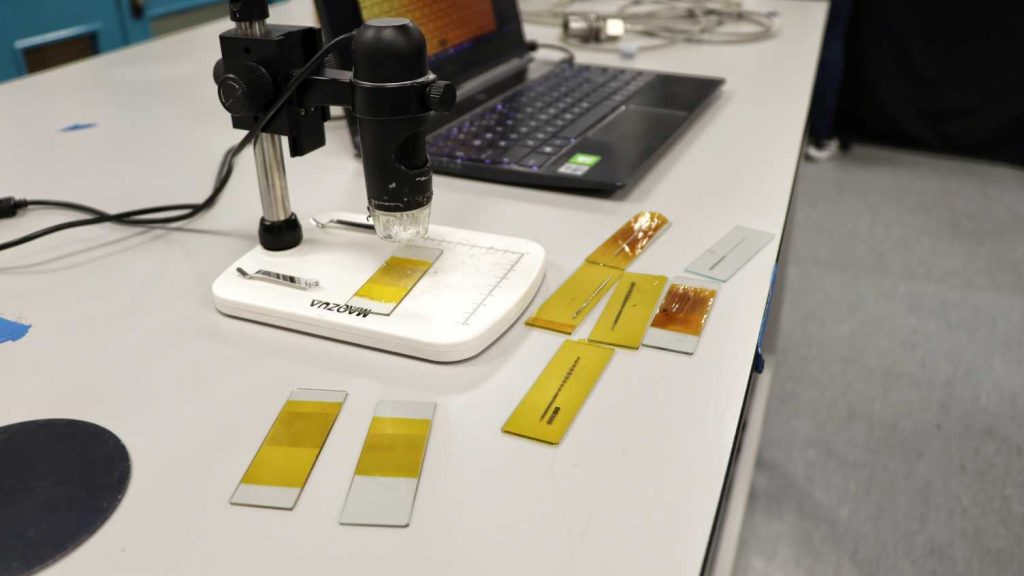

Featured image shows the researchers’ 3D printed antennas. Photo via the University of Sheffield.