Researchers at the University of Pittsburgh’s Swanson School of Engineering together with software company Ansys Inc. (NASDAQ:ANSS) are to carry out research in 3D printed parts with $500,000 funding from NASA. The money is from NASA’s Early Stage Innovations (ESI) grant which, this year, has been awarded to 13 different university research proposals.

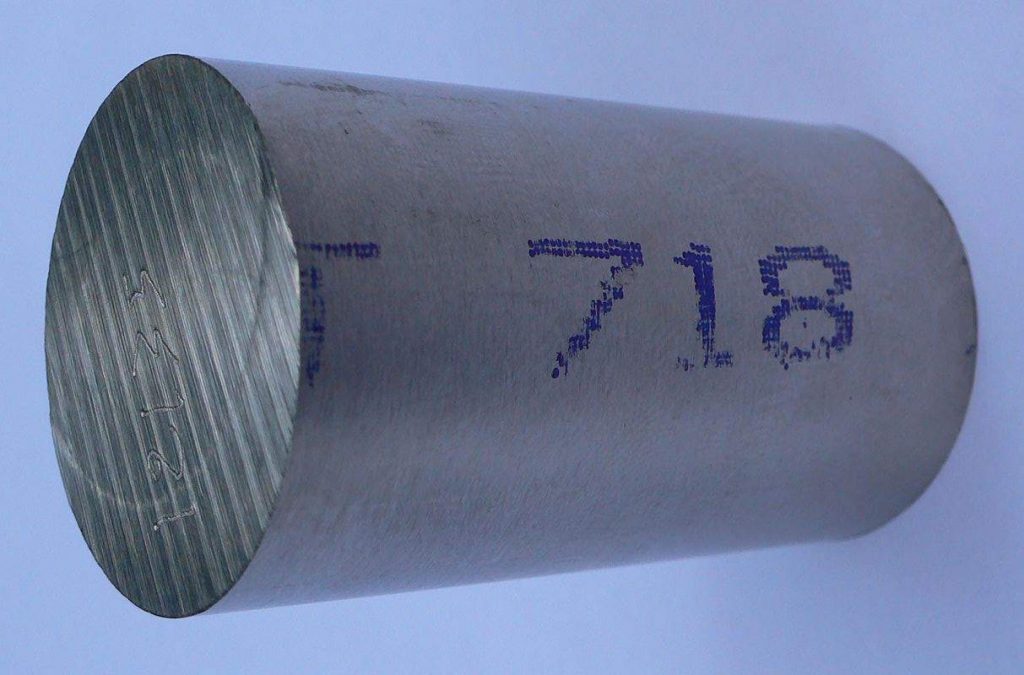

Laser melting of Inconel 718 alloy

The research, titled Prediction of Microstructure Evolution in DMLM (Direct Material Laser Melting) processed Inconel 718 with Part Scale Simulation, will be headed by Dr. Albert To, Director of the Ansys Additive Manufacturing Research Laboratory at the University of Pittsburgh. The overall goal is to ‘[create a] robust simulation toolkit capable of predicting microstructure in an as-fabricated AM part given the process parameters.’ Put simply, this tool will evaluate the strength of 3D printed metal for use in aerospace engineering, focusing on Inconel 718, a Nickel-Chromium ‘superalloy’ resistant to high temperatures and tensile pressure.

In a statement at the University, Dr. To further explains the concept behind the research as follows:

Additive manufacturing now allows us to produce complex metal components that are strong enough to replace machined parts in mechanical applications. However, because of the process parameters and materials used in AM, the microstructure within a part or between different parts can vary widely.

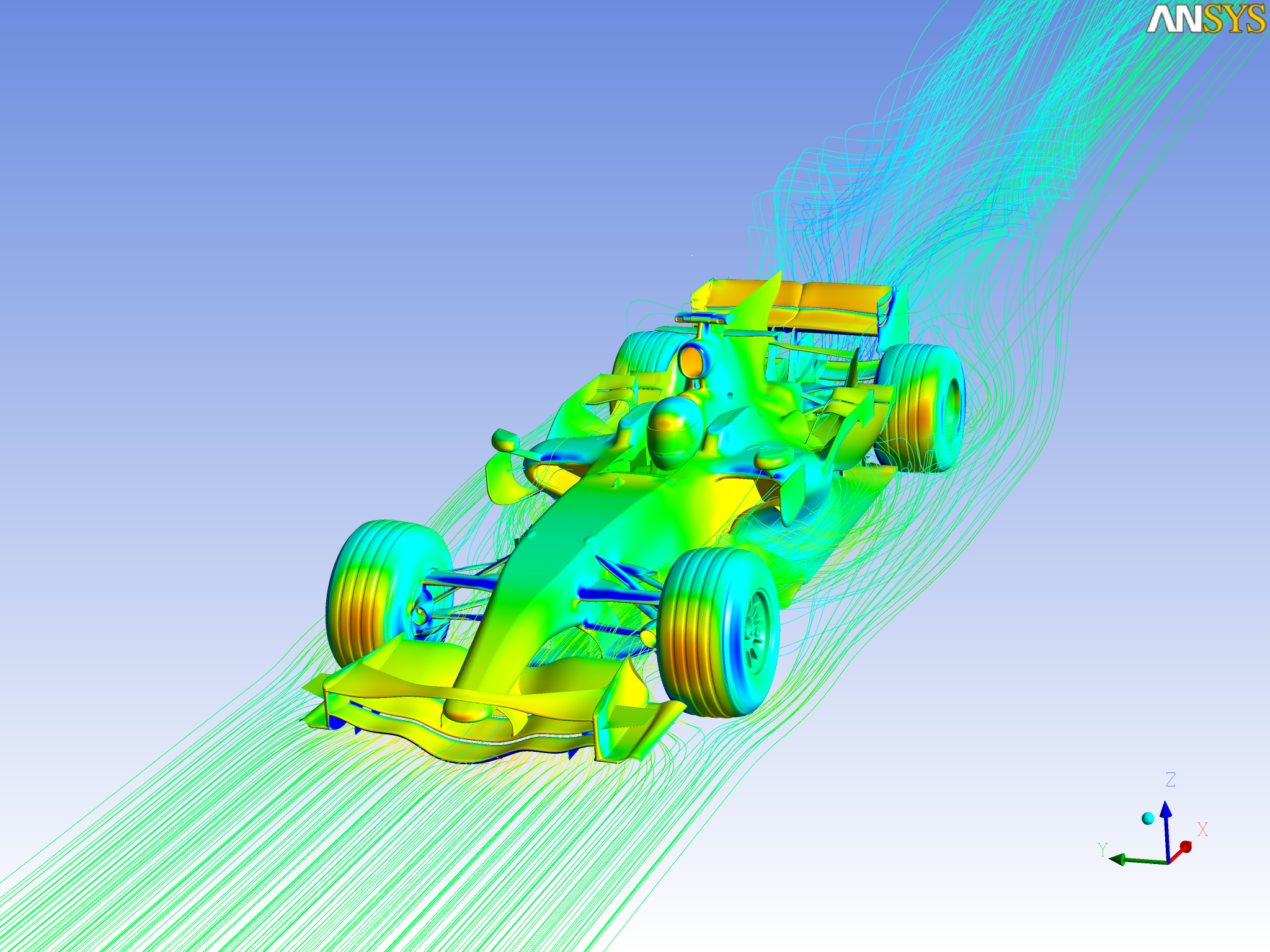

Ansys design simulation

Research partners Ansys are Pennsylvania-based leaders of computational fluid dynamics (CFD) simulation. The company’s proprietary software helps to solve queries for various areas of engineering by predicting how designs will fare in real life situations. One particularly high-profile use case for Ansys is work with Red Bull Racing for which they won the Drivers’ and Constructors’ Championship in 2010.

Early stage innovations

The ESI grant will span over two years with $250,000 awarded for each year and is given as part of the Space Technology Mission Directorate (STMD) which focuses on space technology research of high-priority. There are three research projects involving additive manufacturing receiving the ESI grant this year with Ohio State University and Carnegie Mellon University also receiving funding. Though NASA’s budget is being continually cut, it seems that additive manufacturing is one of the areas in which cost won’t be spared. NASA Jet Propulsion Laboratory (JPL) are also spending time developing new materials that could help their planned mission to Mars.

Featured image of The Swanson School of Engineering. Image via GBBN.