NASA and satellite launch company Virgin Orbit have produced a working 3D printed combustion chamber for a rocket engine. Made using copper, the component is the product of a partnership between the two organisations which seeks to advance adoption of 3D printing across the commercial space sector and reduce the cost of future NASA missions.

Formed in 2017, Virgin Orbit has been working with NASA experts in combustion and additive manufacturing for the past two years at the Marshall Space Flight Center in Alabama (MSFC), as well as other centers in Cleveland and California.

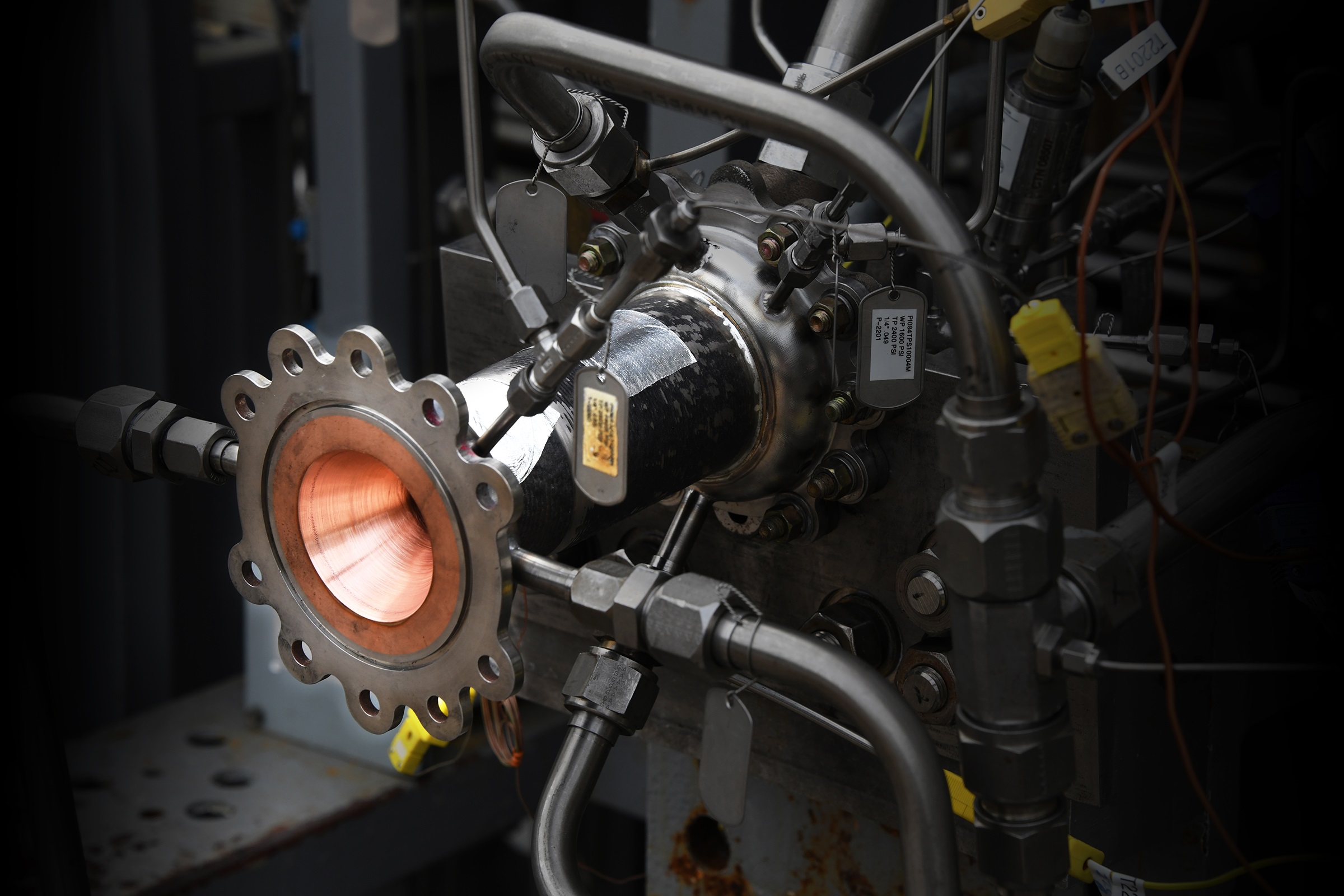

As part of a continuing development process, the latest 3D printed combustion chamber successfully completed a test-firing at MSFC, delivering up to 2,000 pounds of thrust.

3D printing rocket components

Combustion chambers are a crucial component of all rocket engines. Here the propellants mix and ignite, generating extremely high pressure temperatures up to 5,000°F (2760 °C).

This requires complex, internal cooling channels which are filled with gases cooled to less than 100°F (38°C) above absolute zero. The complex cooling process makes combustion chambers one of the most difficult engine parts to develop while maintaining low cost and lead times.

According to NASA senior engineer and Virgin Orbit project lead Paul Gradl, “Traditionally, it takes many months to manufacture, test and deliver a conventional combustion chamber. We can reduce that time considerably.”

“Additive manufacturing is primed to augment and enhance traditional processes. It provides new design and performance opportunities and yields a highly durable piece of hardware – and with this partnership, we’re advancing that capability even further.”

Adding to the complexity of the design, this project also faces the challenge of 3D printing a multimetallic copper component. Copper is of particular interest to the aerospace industry due to its high thermal conductivity, excellent creep (deformation) resistance, and strength at elevated temperatures and affordability. However, due to its natural luster copper has been proven to be a difficult material for additive manufacturing as it reflects the heat applied by a laser beam.

Nevertheless, several aerospace companies have already succeeded in producing parts using copper-based alloys. Private space exploration company Aerojet Rocketdyne revealed its copper-based, SLM manufactured, RL-10 rocket thrust chambers in 2017. Launcher, an aerospace startup, successfully test-fired a EOS 3D printed copper rocket engine in 2018. NASA has also had some prior success with the material, 3D printing the first full-scale copper rocket engine in 2015.

Producing a multimetallic copper combustion chamber

To create the multimetallic combustion chamber, Virgin Orbit engineers used a proven NASA additive copper alloy, GRCop-84, developed in 2014, that lines the inside of the chamber. The material was then printed by Virgin Orbit’s hybrid additive/subtractive machine, which applied a second bimetallic super-alloy jacket and then machined the part to the correct size.

Earlier this year, researchers from NASA announced the development of GRCop-84’s eventual replacement, GRCop-42. The high strength, high conductivity copper-based alloy, was created by a team from the NASA MSFC and the NASA Glenn Research Center (GRC) in Ohio. The hope is for GRCop-42 to have a higher thermal conductivity while matching the strength of GRCop-84.

The benefit of developing multimetallic parts is that you can take advantage of the individual mental’s distinct properties (such as strength or thermal conductivity) to create a more robust, higher performing end product.

Commenting on the incorporation of different metals, Kevin Zagorski, Propulsion Advanced Manufacturing manager at Virgin Orbit said, “The combination of multiple optimized materials and additive manufacturing technologies we’ve employed represents a significant advancement from the compromises typically made in the production of 3D printed rocket engine combustion chambers.”

“Information gained from our partnership with NASA will be key in applying these technologies to further improve cost, performance and lead time of Virgin Orbit’s propulsion systems for the LauncherOne vehicle,” he added.

The combustion chamber was tested in late 2018/early 2019, using high-pressure liquid oxygen/kerosene propellants, which generated more than 2,000 pounds of thrust in a series of 60-second test fires.

Advancing space exploration with 3D printing

The combustion chamber project forms part of NASA’s ongoing work to advance 3D printing technology to improve access to space and make launch technology safer, faster and more cost effective.

In April this year, NASA awarded a $5.2 million contract to the National Center for Additive Manufacturing Excellence (NCAME) at Auburn University, to help improve the performance of its liquid rocket engines, like the RS-25 Space Shuttle main engine (SSME). The same month it also revealed that it was using 3D printing to help insulate vulnerable parts of its new deep space rocket that will take astronauts to the moon in 2024. Prior to this, NASA awarded a $100,000 grant to researchers at West Virginia University (WVU) in 2017 to explore the use of 3D printed titanium dioxide foam aboard the International Space Station (ISS).

Don’t forget to vote for the 2019 3D Printing Industry Awards.

Subscribe to our 3D Printing Industry newsletter and follow us Facebook and Twitterfor the latest news in additive manufacturing.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows the combustion chamber undergoing tests at at NASA’s Marshall Space Flight Center in Huntsville, Alabama. Photo via NASA.