3D printer manufacturer and additively manufactured electronics (AME) specialist Nano Dimension has closed a definitive agreement to acquire Nanofabrica, a developer of precision 3D printing technologies.

Under the agreement, Nano Dimension will pay the shareholders of Nanofabrica an unconfirmed amount between $54.9 million and $59.4 million.

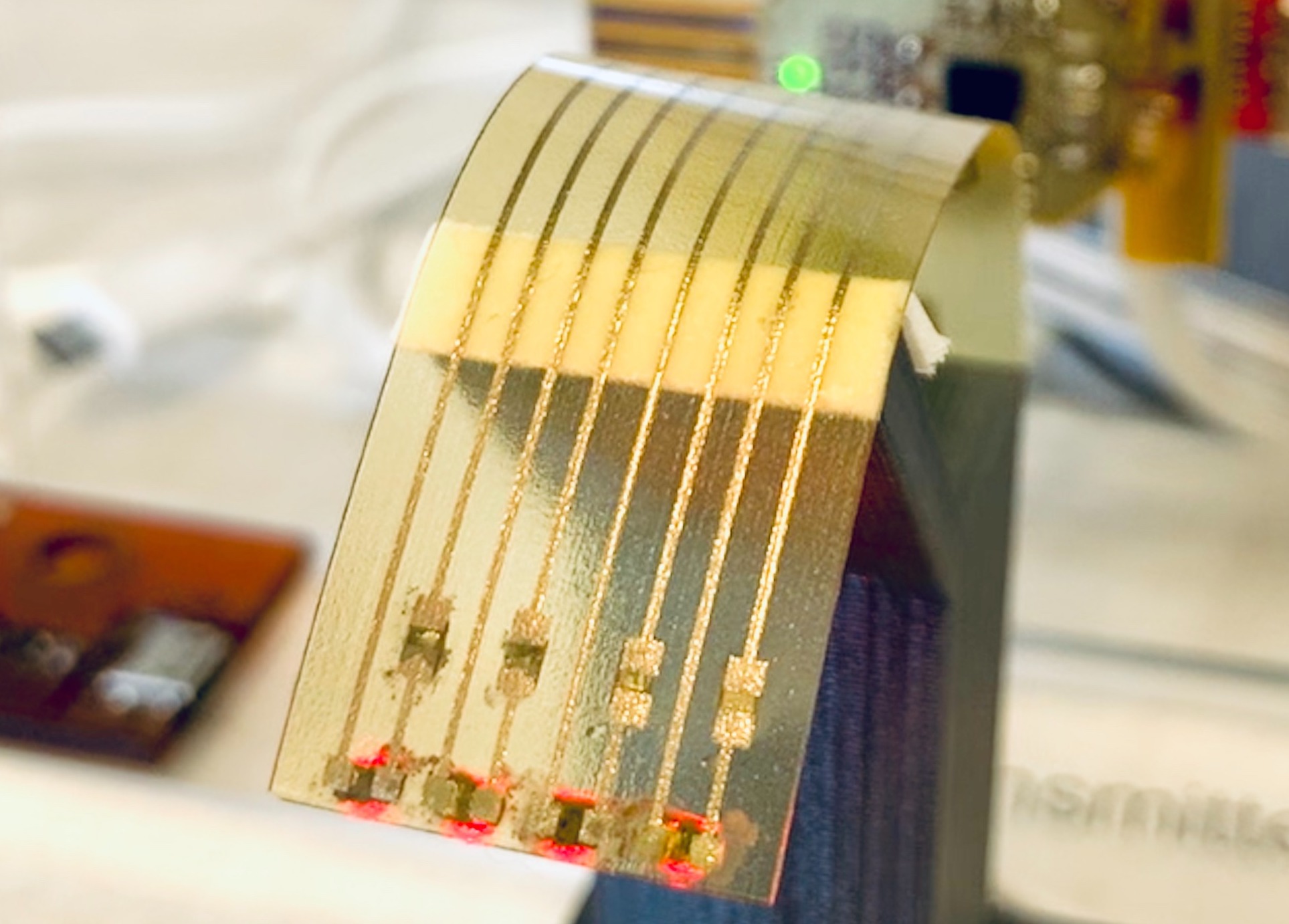

The move will see Nanofabrica’s micro-mechanic 3D printing technology integrated into Nano Dimension’s machines to advance the 3D printing of precision Hi-Performance Electronic Devices (Hi-PEDs), alongside the building of an artificial intelligence (AI) and machine learning (ML) “distributed digital fabrication application”.

“Nanofabrica fits Nano Dimension’s vertical original equipment manufacturer’ (OEM) target markets, and as such will be leveraged by the distribution channels and go-to-market efforts of both,” said Yoav Stern, CEO of Nano Dimension. “In parallel, our mutual vision is to merge the technologies of our micro-electronic 3D fabrications machines for Hi-PEDs with Nanofabrica’s micro-mechanic 3D printing.

“The future of Hi-PEDs and miniaturized high-performance printed circuit boards (PCBs) is interlaced with micro-mechanical printing applications to fit the adage ‘the next big thing is small.”

Nanofabrica’s micro 3D printing technology

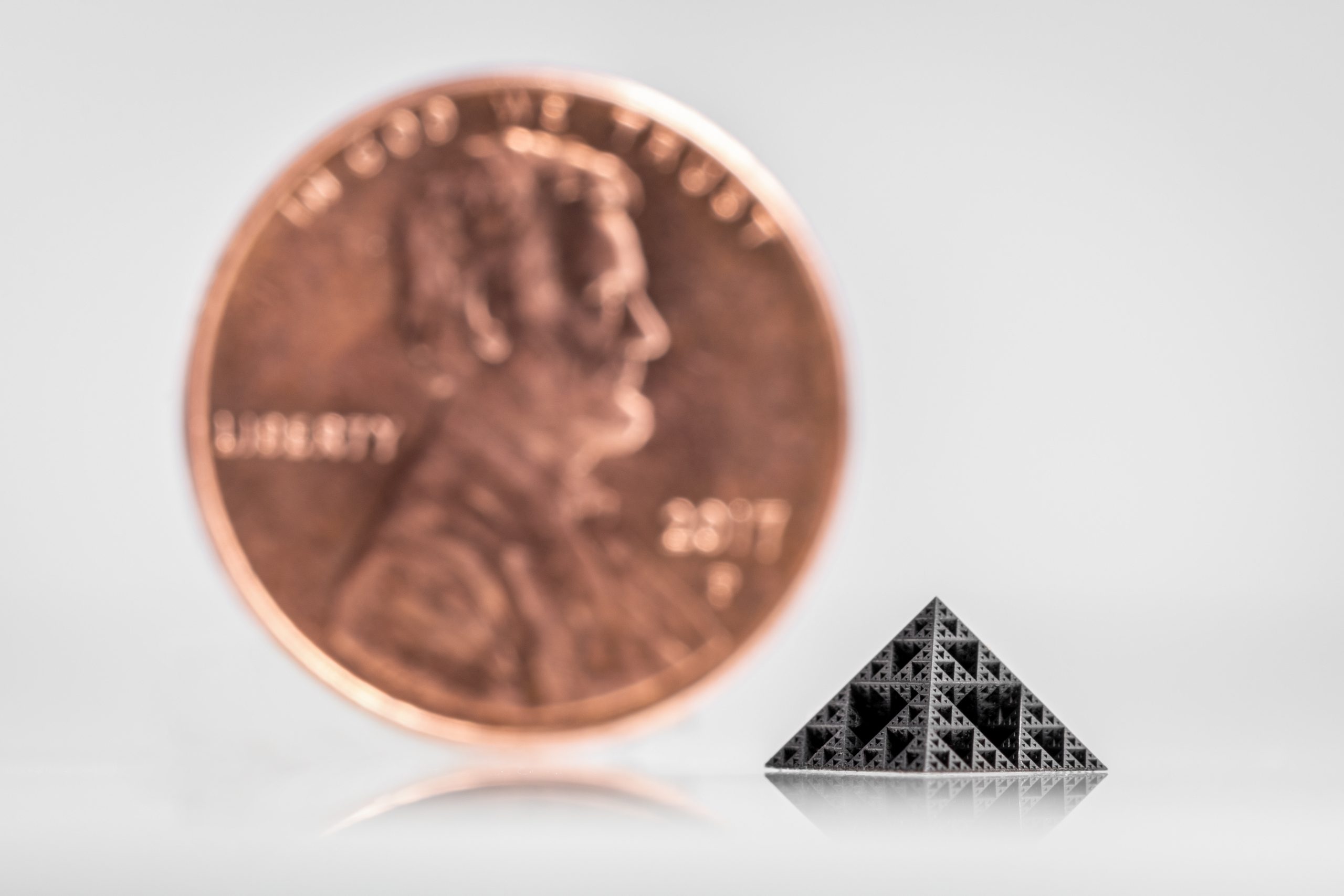

Since its establishment in 2016, Nanofabrica has become a leader in the microscale additive manufacturing sector with its proprietary microscale 3D printing technology. The company’s patented process is based on a Digital Light Processing (DLP) engine, and Adaptive Optics (AO), a technology used to improve image distortions in optical devices such as telescopes.

The Micro Adaptive Projection technology produces 3D printed parts with micron and sub-micron levels of resolution and surface finishes for applications within the aerospace, aviation, high-end electronics, automotive, and medical sectors, among others.

Nanofabrica commercialized its technology in 2019 with the launch of its micron-level resolution industrial 3D printers, the Workshop System and the Industrial System. Commercialization was further supported that year by the Siemens Dynamo program, which aims to serve as a commercialization vehicle for startups with Siemens and its customers.

In May last year, Nanofabrica raised $4 million in a funding round led by Microsoft’s venture arm M12 and venture capitalists NextLeap Ventures to further its research and development goals and grow its sales.

The company’s flagship Tera 250 additive manufacturing system is designed to produce two different types of parts: micro-parts and larger parts with micro-features. The Tera 250 operates on a micro-DLP light engine and is capable of achieving a one-micron resolution over a (relatively) sizable build volume measuring 50 x 50 x 100mm.

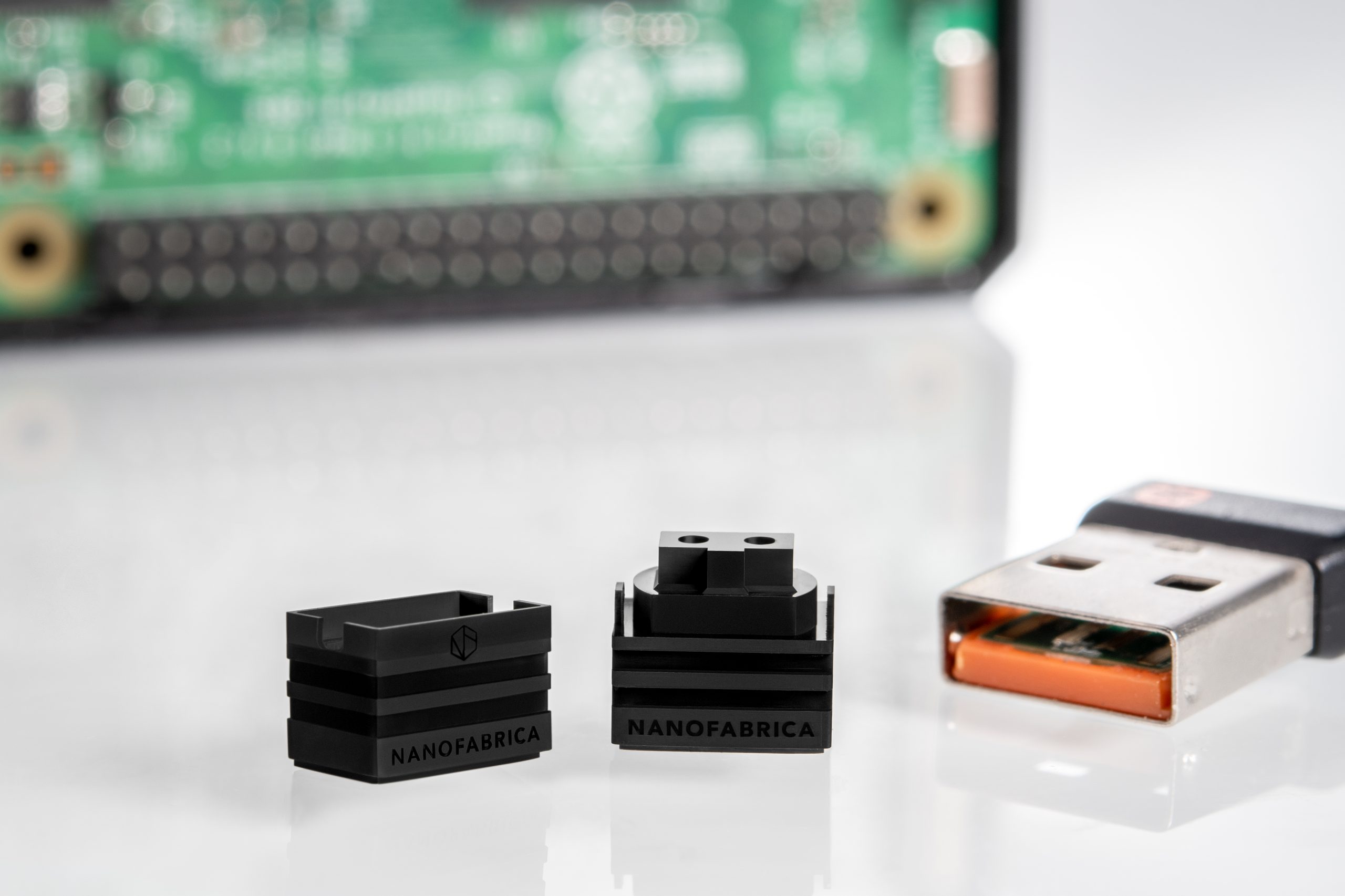

The system is well-suited for custom applications in micro-optics, microelectronics, microfluidics, and life sciences, including electronics casings, micro springs, and small-scale, minimally invasive medical implants and surgical devices.

Ultra-high precision printing of AMEs

The high-precision applications of Nanofabrica’s technology overlap the typical markets within which Nano Dimension operates, such as aerospace, aviation, high-end electronics, medical, optics, research, and more.

Through the acquisition of Nanofabrica, Nano Dimension will merge the company’s technology and capabilities with its own micro-electronic 3D printers in order to form a “distributed digital fabrication application” to enable digital control of the entire supply chain for AMEs.

“Nanofabrica’s machines fit the larger picture of Nano Dimension’s vision, aiming to establish Industry 4.0 solutions, which entail building an AI/ML ‘distributed digital fabrication application’ rather than just building machines as capital equipment,” said Stern. “The AI/ML/DL Distributed Electronic Fabrication Application’ will be furnished by additional edge devices in the form of Nanofabrica’s 3D micro printing systems.”

According to Stern, the end goal of the platform is to be able to maintain an inventory of high-end PCB devices, micro-mechanical parts and Hi-PEDs in digital form. This will allow users to print these parts when and where they need them while maintaining quality and achieving the “highest yield and throughput possible for that point in time”.

Details of the acquisition

The agreement between the two companies will see Nano Dimension pay Nanofabrica’s shareholders an amount between $54.9 million and $59.4 million, with between $23 million and $27.5 million to be paid in cash, depending on Nanofabrica meeting certain performance milestones.

Around $32 million of the total will be offered in American Depositary Shares (ASDs) – shares issued by American banks or brokers as a form of equity security to simplify foreign investing for American investors – of which some 30 percent cannot be sold for various periods up to 24 months after the closing of the transaction.

Additionally, certain cash payments will be based on Nanofabrica’s revenue and gross margin performance over the next 12 months.

Nanofabrica’s scientists and engineers are all expected to join Nano Dimension alongside the company’s two founders, Jon Donner and Eyal Shelef. Donner, who will become General Manager of the Nanofabrica division of Nano Dimension, believes the acquisition is an exciting day not only for Nanofabrica but also the wider field of precision manufacturing.

“We have set out on a mission to transform this traditional analog non-environmentally friendly industry, and by joining the segment leader, Nano Dimension, we will be able to fulfill our mission statement much faster and in more elaborate fashion,” he said.

According to Donner, combining the advanced capabilities of deep learning together with Nanofabrica’s manufacturing systems will hopefully improve printing speed by five times and yield by 20 times.

“Henceforth, by integrating our ultra-precise miniaturization capability with Nano Dimension’s Hi-PEDs, we shall become a transformative power in our vertical markets,” he continued. “Nano Dimension-Nanofabrica’s combined offering will greatly increase the number of applications that can be relevant for mass-manufacturing on our planned neural network of digital manufacturing systems.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows electronic device casings are a key application of Nanofabrica’s technology. Photo via Idan Gill/Nanofabrica.