Binder jet 3D printer OEM ExOne is set to develop a portable 3D printing factory for the U.S. Department of Defense (DoD) after being awarded a $1.6M contract by the Defense Logistics Agency (DLA) last August.

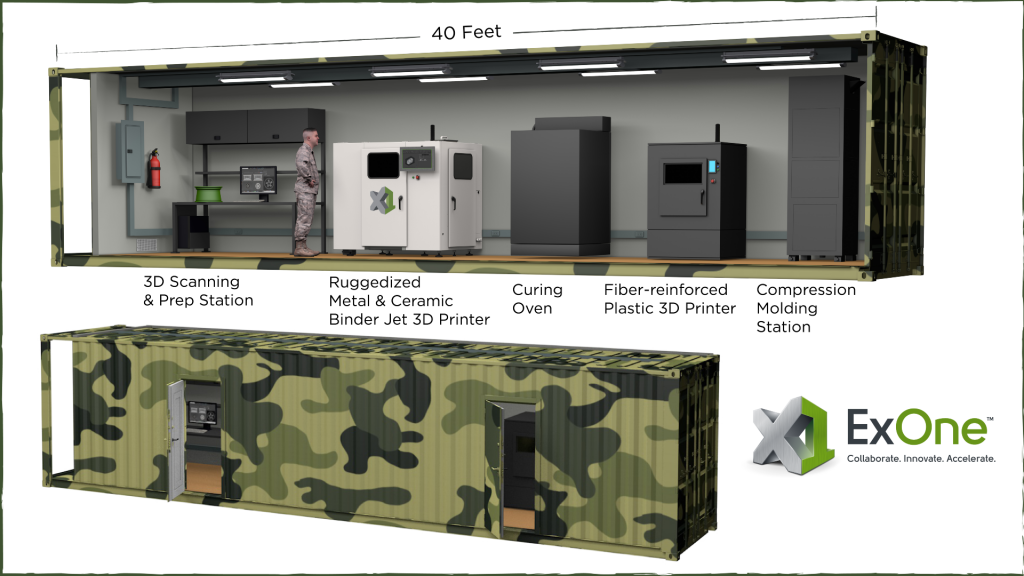

Currently under development, the ‘rugged 3D printing pod’ will be housed in a standard 40-foot shipping container. It will contain everything the armed forces might need to address the problem of spare part production in the field and will be deployable via land, air, or sea. To help speed up the development of the factory, ExOne is working in collaboration with materials engineering firm Dynovas and tooling manufacturer Applied Composites.

John Hartner, CEO of ExOne, states, “Binder jet 3D printing is a critical manufacturing technology for military use because of its speed, flexibility of materials, and ease of use. We’re excited to collaborate with the U.S. Department of Defense and other partners to make our 3D printers more rugged for the military, which will also benefit our other manufacturing customers. Most importantly, we know that years from now, our technology will play an important role in filling critical needs quickly.”

Ruggedizing binder jetting for the field

The majority of the funding from the contract will go towards improving the ruggedness of ExOne’s existing commercial 3D printers. This will improve their suitability for a wide range of harsh operating conditions to better prepare them for field deployment.

The company will also be developing a special military-edition of one of its industrial binder jetting systems, one that will feature a unique body style and upgraded features to convert it into a military-grade manufacturing engine. ExOne states that it will be able to 3D print the company’s entire suite of 20+ additive manufacturing powders, including ceramics and metals.

A portion of the funding will also go towards simplifying the use of ExOne’s 3D printing technology with software and training schemes, such that the pod can be used with minimal technical knowledge. In addition to the ruggedized 3D printer, the portable factory will contain a fully-functional 3D scanning and print preparation station, a curing oven, a third-party fiber-reinforced composite 3D printer, and even a compression molding station.

A self-contained portable supply chain

The pod is ultimately intended to help support war theaters, disaster relief missions, and other remote operations where conventional supply chain links may be cut off. Military teams will be able to 3D print spare parts as and when needed on-site, reducing both logistical costs and the downtime of potential crisis situations from weeks to days or hours.

Since part libraries can be stored digitally, the pod will also eliminate the need to carry around cumbersome inventory. In cases where a digital file is not readily available, the pod will enable military personnel to either 3D scan the physical version of a part or just design an entirely new component using the CAD-capable PC stored in the pod’s preparation station.

Over in the Netherlands, the Dutch Navy recently had a similar idea to improve its on-demand spare part manufacturing capabilities. The Navy has developed what it is calling the Additive Manufacturing Container for Defence (AMCOD), a shipping container that houses high-performance INTAMSYS 3D printers on board frigate ships. Each container is kitted out with air conditioning, ventilation, and an uninterruptible power supply (UPS) for round-the-clock polymer part production.

Elsewhere, the Australian Army has previously carried out field exercises using SPEE3D’s WARPSPEE3D additive manufacturing systems. Using an upgraded machine, the soldiers were able to 3D print end-use spare parts in extreme temperatures of up to 37°C over the course of two weeks.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows ExOne’s portable 3D printing factory. Image via ExOne.