Mitsubishi Electric Corporation, a major Japanese manufacturer of electronics and electrical equipment, has announced the launch of a new metal 3D printing system.

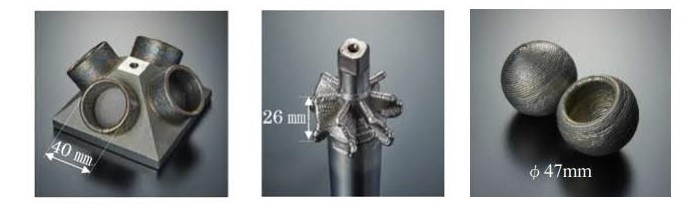

The upcoming AZ600 is a directed energy deposition (DED) 3D printer that’ll be available in two models. According to the firm, the system will be laser-based and work by melting welding wires to 3D print near-net-shape metal parts. Customers will also be able to leverage the AZ600 for component repair and maintenance applications in sectors such as aerospace, automotive, and maritime.

To complement the launch of the 3D printer, Mitsubishi is also establishing a new contract printing service that will utilize the metal system. The firm will offer product design consultation, prototyping, and general advice about metal 3D printing, expecting the move to help accelerate the adoption of additive manufacturing.

Mitsubishi and additive manufacturing

It’s always interesting to see big-time multinationals investing in additive manufacturing, but this isn’t Mitsubishi’s first run-in with 3D printing. In 2018, the company developed a high-precision metal “dot forming” DED 3D printing process to manufacture near-finished parts for the automotive and aerospace industries.

Last year, Mitsubishi Electric also partnered with UK-based post-processing specialist Additive Manufacturing Technologies (AMT) to develop a fully automated post-processing machine for 3D printed polymer parts. Reportedly the first machine of its kind to be approved by safety and consulting firm Underwriters Laboratories (UL), the device comprises AMT’s PostPro3D chemical vapor smoothing system and Mitsubishi’s articulated robotic arm technology.

In the materials space, Mitsubishi Heavy Industries (MHI) subsidiary Mitsubishi Power has previously signed a technology licensing agreement with french metal processing specialist Aubert & Duval for the production of 3D printable metal powders. The deal marked the first step towards the full-scale inauguration of Mitsubishi Power’s additive manufacturing business.

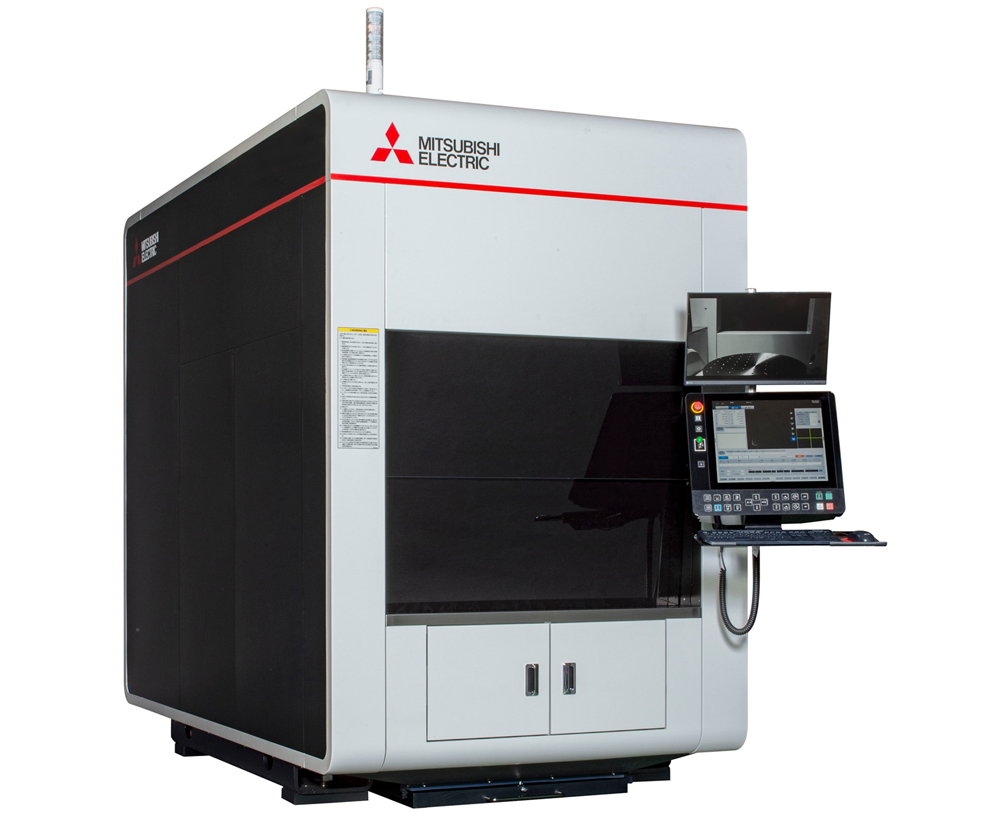

The AZ600 3D printer

It’s no secret that powder-based 3D printers often have issues with material management, workability, and safety, requiring an abundance of specialized equipment and PPE. To address these issues, Mitsubishi has developed its AZ600 to process welding wires as printing materials instead. As well as making for a ‘cleaner’ 3D printing workflow, the design consideration will make the system more accessible to companies new to additive manufacturing.

The AZ600 will feature a laser DED tool head, a 5-axis spatial control system, and the ability to precisely control the processing conditions of a build. According to Mitsubishi, this combination is a world-first. As well as printing new parts from scratch, the machine will allow users to print onto existing components, as is the case with many DED 3D printers.

Looking at the two different printer models, the AZ600-F20 will feature a 2kW oscillator while the AZ600-F40 will come complete with a 4kW oscillator. The firm’s sales target is to deliver 100 of each of the models every year.

Considering the environmental impacts

Mitsubishi states that the AZ600 is also set to contribute to the firm’s decarbonization goals. In recent years, there’s been a growing desire to slash CO2 emissions in the manufacturing sector (and every sector for that matter), meaning there’s a need to develop energy and material-efficient manufacturing methods. Mitsubishi expects there to be an increased demand for metal 3D printers, in particular.

In light of this, the AZ600 was reportedly designed with low energy consumption and shorter processing times in mind. The ability of the system to produce near-net shapes also allows for minimal material waste, enabling users to flexibly design large-scale metal parts with optimized weights and geometries.

Mitsubishi will exhibit the AZ600 3D printer at the Additive Manufacturing Expo from March 16-18 at Tokyo Big Sight. Further details such as the technical specifications will be unveiled then.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the AZ600 3D printer. Photo via Mitsubishi.