Mitsubishi Power, a subsidiary of Mitsubishi Heavy Industries (MHI) Group, has concluded a technology licensing agreement with french metal processing specialist Aubert & Duval for the composition and manufacture of 3D printable metal powders.

The deal marks the first step towards the full-scale inauguration of Mitsubishi Power’s additive manufacturing business, combining Aubert & Duval’s metal powder expertise with Mitsubishi’s proprietary 3D printing technologies.

MHI’s move into 3D printing

Since entering the 3D printing market in 2014 with a metal-forming 3D printer developed by compatriot company Matsuura Machinery, Mitsubishi’s various subsidiaries have increasingly adopted additive manufacturing within their processes.

In 2018, Mitsubishi Electric Corporation developed a precision metal printing process with “dot forming” Direct Energy Deposition (DED) to increase the productivity of manufacturing near-finished parts for the automotive and aerospace industries. A month later, the subsidiary aided UK-based post-processing systems manufacturer Additive Manufacturing Technologies (AMT) in speeding up automated post-processing in its PostPro3D system.

After acquiring 3D printing filament supplier Dutch Filaments, Mitsubishi’s chemical arm, Mitsubishi Chemical Performance Polymers (MCPP), partnered with Belgium machine development startup Colossus to test 10 material compound profiles on its Colossus FGM 3D printer. According to Colossus, the printer was the first of its scale to use rPET, recycled PET, and rPP, recycled Polypropylene profiles.

Last year, MCPP installed a high-volume 3D printing production unit from Vancouver-based 3D printing startup 3DQue, called the QPoD at its materials testing laboratory in Michigan. Most recently, Mitsubishi’s chemical branch partnered with German materials startup firm AM Polymers to develop polybutylene terephthalate (PBT) powder products for industrial 3D printing.

The technology licensing agreement

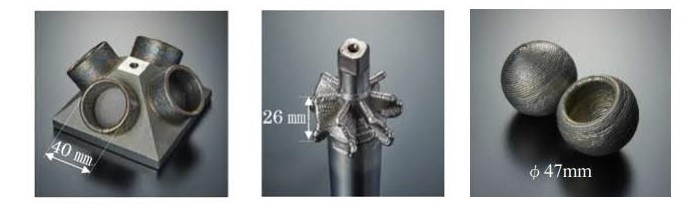

Mitsubishi Power deploys proprietary material technologies in metal 3D printing to prepare raw materials for various applications and enhance the performance of powder manufacturing equipment. Mitsubishi’s specially developed gas nozzles can be integrated into gas atomization systems that produce metal powder materials by atomizing inert gas into vacuum-fused metals.

Aubert & Duval provides the aerospace, energy, and defense industries with high-performance alloys and metals, and was chosen by Mitsubishi to be a collaborative partner in developing its 3D printing business as a result of its expertise in these sectors.

Mitsubishi’s technologies will be combined with Aubert & Duval’s know-how in metal powder manufacturing to develop powders optimized for use in additive manufacturing processes. The partnership is expected to notably improve the performance of 3D printed products, and will enable Mitsubishi to become involved in the metal additive manufacturing process from material development to final product manufacture.

The AM-Zone

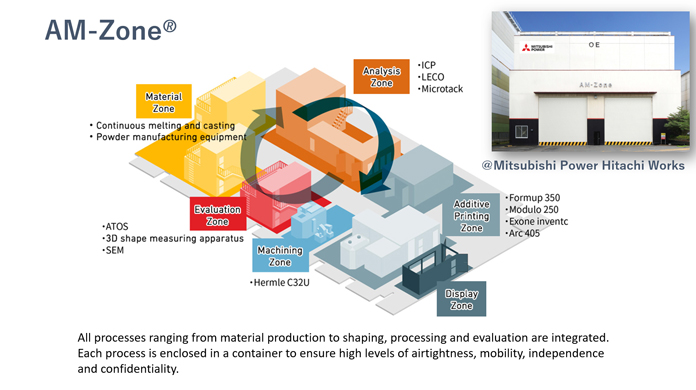

In September, Mitsubishi Power created a new additive manufacturing development facility at its Hitachi Works in Ibaraki Prefecture. Called the AM-Zone, the facility is equipped with powder manufacturing equipment and several metal 3D printing systems, capable of fulfilling the entire additive manufacturing process from powder development through to product finishing.

The AM-Zone conducts tours and other activities in order to promote the uptake of additive manufacturing technologies, with online tours currently on offer in light of the Covid-19 pandemic. Looking ahead, Mitsubishi Power will look to reduce labor expenditure by integrating remote operations and digital manufacturing.

Mitsubishi hopes that through its partnership with Aubert & Duval and the creation of its AM-Zone, the firm will become involved in all areas of the metal 3D printing process. The company believes the development of this new business area will enable it to contribute to the next phase of industrialization for the energy sector and beyond.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows cut model of small class gas turbine stationary vane (MHA3300). Image via Mitsubishi Power.