Researchers from the Massachusetts Institute of Technology (MIT) have developed a 3D printing system that uses off-the-shelf varnishes to finish objects with realistic, spatially varying gloss patterns.

Working with colleagues from Università della Svizzera italiana, the Max Planck Institute for Informatics, and Princeton University, MIT researcher and mechanical engineer Michael Foshey hopes the printer will bring the concept of “visually perfect” 3D printing closer to reality, where the difference between an object and its 3D printed replica is almost impossible to tell.

Potential applications for the developed halftoning technology could include fine art replicas for museums and creating more realistic-looking prosthetics.

Challenges to 3D printing varnishes

A surface’s glossiness refers to how much light it reflects; a high gloss surface is reflective while a low gloss or matte surface is unreflective. Glossier varnishes are less viscous than their matte counterparts and dry into a smoother surface. The larger polymers in matte varnishes, meanwhile, can clog up the thin channels in 3D printer nozzles.

Previous research has been conducted into how halftoning can improve the surface quality and color of 3D printed parts by Purdue University. The paper explored a halftoning algorithm that focused on optimizing individual voxels in relation to HP’s multi-jet fusion technology.

In 2018, German post-production solutions provider DyeMansion launched its VaporFuse Surfacing (VFS) technology, which gives a glossy finish to 3D printed parts by applying an industry-safe solvent that dissolves particles on their surface.

MIT’s variable gloss 3D printer

MIT’s method involves initially 3D printing an object with high gloss and support structures covering the areas where a matte finish is desired. The support material is then removed to achieve the required roughness of the final surface.

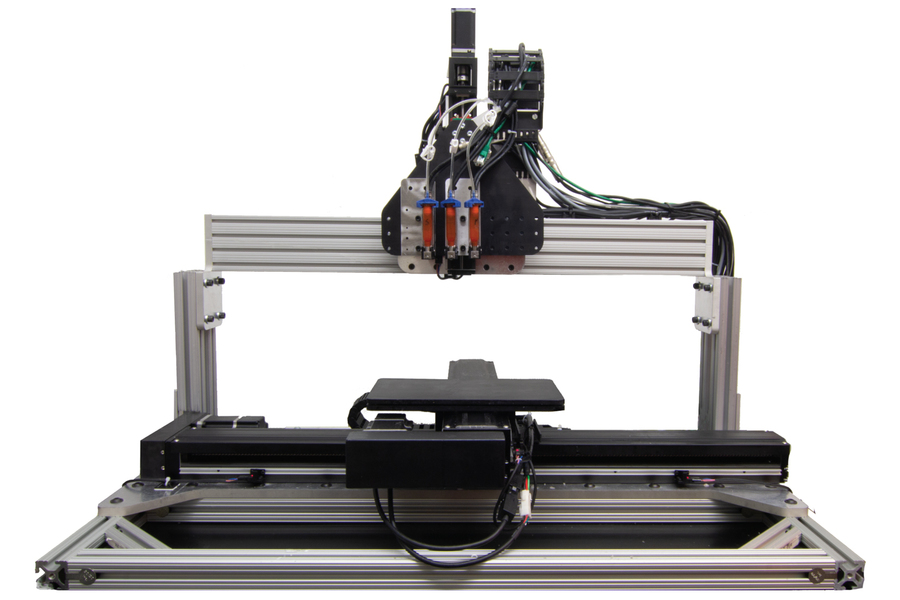

To do this, the researchers designed a printer with large nozzles that can deposit various-sized droplets of varnish with high viscosities and large particle sizes. Stored in a pressurized reservoir, the varnish is released onto the printing surface by the opening and closing of a needle valve. The droplet size can be controlled by altering the reservoir pressure and speed of the needle valve; the more varnish released, the larger the droplet.

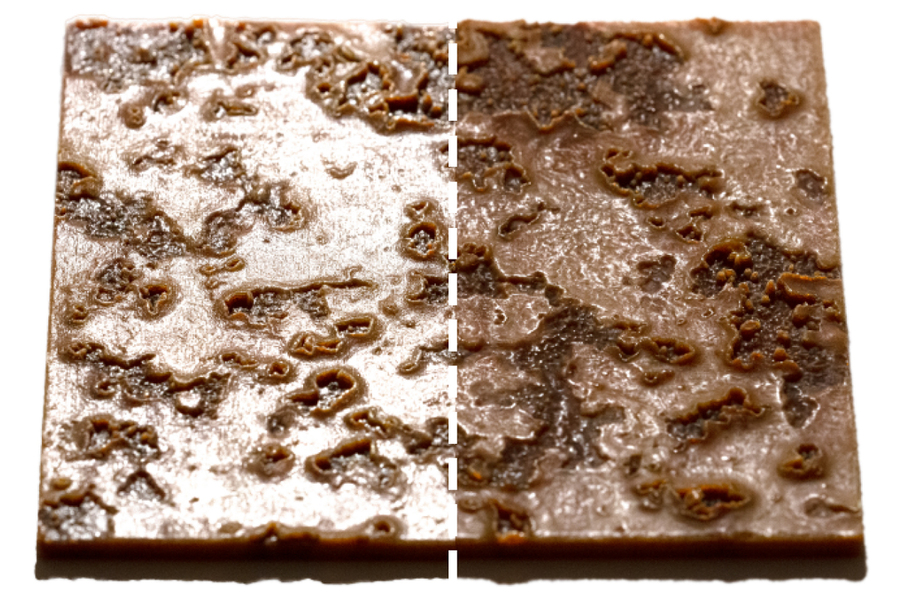

To achieve spatially varied gloss, the researchers used a halftoning technique, arranging discrete varnish droplets in patterns that appear like a continuous surface when viewed from a distance. Then, they integrated one glossy, one matte, and one in-between varnish into the printer’s pre-programmed halftoning pattern to print continuous, spatially varying shades of gloss across the object’s surface.

The printer’s output is determined by a software pipeline developed by the team, in which a user selects a desired gloss pattern to be printed on an object. The printer runs a calibration process to choose the correct halftoning pattern to use in the final print job, based on the reflectance of the calibration patterns.

The researchers demonstrated the results on what they call “2.5D” objects, which are mostly-flat printouts with textures ranging half a centimeter in height. Next, the team will continue developing the technology for use on fully-3D objects, with the potential for further integration with commercial 3D printers in the future.

Further details of the study can be found in the article titled “Towards spatially varying gloss reproduction for 3D printing”, which will be presented at next month’s SIGGRAPH Asia conference. The study is co-authored by M. Foshey, M. Piovarči, W. Matusik, V. Babaei, S. Rusinkiewicz, and P. Didyk.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Left: traditional 3D printing which doesn’t have varying reflectivity. Right: the researchers’ improvements, where one can choose which surfaces are glossy and which are matte. Image via MIT.