Insiders and analysts predict the 3D printing trends to watch in our latest series of articles focused on the future of 3D printing.

Researchers from the Massachusetts Institute of Technology (MIT) have developed a new method of 3D printing objects that change their appearance depending on the angle they’re viewed at.

The approach paves the way for ‘programmable objects’ with morphing images, a visual feature that’s largely been limited to flat 2D surfaces until now. The team believes its work can drastically change the way people view product design, with everyday 3D printed objects potentially containing hundreds of different colors and patterns depending on how they’re viewed.

Naturally, the work could also have major implications for the arts, enabling novel fashion designs and sculptures that convey different aesthetics from different sides.

“Our work opens up the idea of what a physical object can be,” says Yunyi Zhu, an MIT graduate student and co-first author of the paper. “It’s part of a larger vision for making dynamic objects that change their appearance, color pattern, and shape. We address appearance, which is one dimension of the concept of reprogrammable objects.”

3D printing lenticular objects

So how does it work? The novelty of the idea lies in its use of 3D printed lenticular lenses, which are tiny lenses that can magnify the colors of the materials they’re placed on top of. Depending on the angle they’re viewed at, lenticular lenses can diffract and project different areas of the image or pattern they cover. The MIT team managed to fit six of these lenses across the surface of a dime.

By 3D printing the lenses (and the curved, patterned surfaces underneath the lenses), it’s possible to create an entire 3D lenticular display, which collectively shows an image that varies based on the viewpoint.

According to Zhu, the biggest challenge in the project was fine-tuning the size of the printed lenses. Smaller lenses offer better resolution but also tend to have more defects, leading to lower image quality. The team eventually settled on a lens diameter of 3mm, as this was the sweet spot.

Various printing orientations and post-processing techniques were also put to the test in a bid to maximize color transmission. The best results were yielded by upwards-facing lenses that were treated with painting varnish.

A free lenticular object design tool

To complement the 3D printing technique, the MIT researchers also developed a free editing software allowing users to design and build their own lenticular objects. To use the tool, users simply upload a 3D model and the desired patterns or images for the surface of the object. The software then automatically calculates the lens placement and patterning that will achieve the desired results. The part, images, and lenses can all be 3D printed in one go.

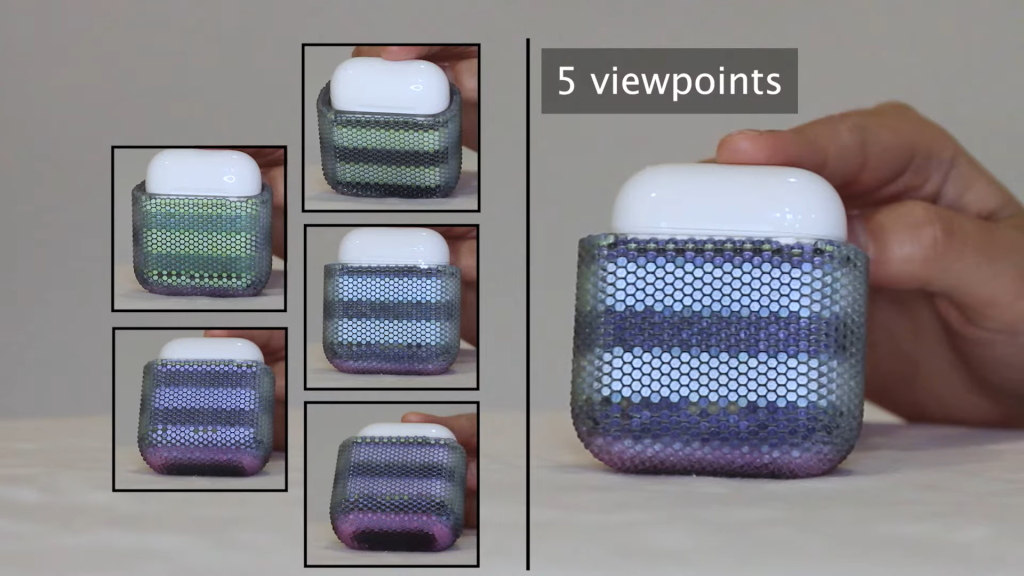

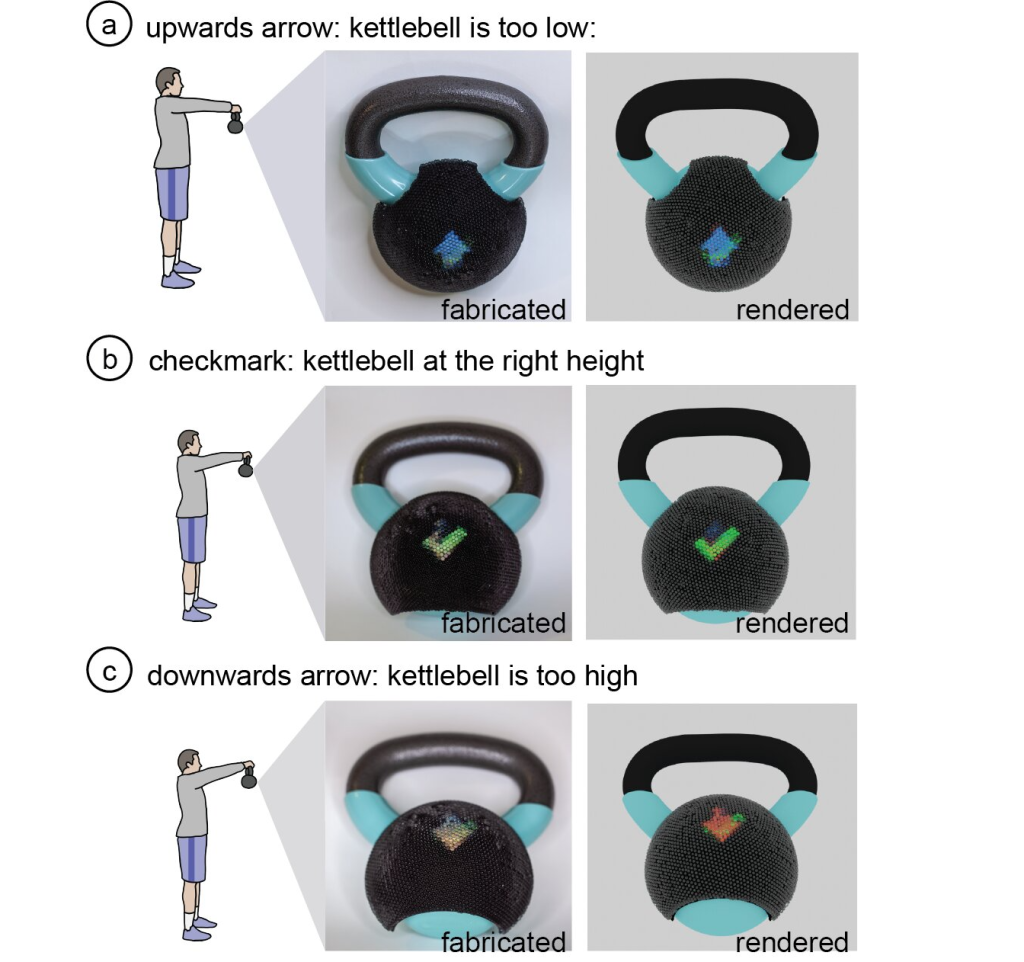

To demonstrate the lenticular 3D printing method, the team has already printed a number of prototypes. This includes an exercise kettlebell that shows the user whether or not they are holding it correctly, a bedside lampshade that displays ‘Good Day’ or ‘Good Night’ depending on the viewing angle, an AirPod case that shimmers, and a shoe that shows a friendly message exclusively to the wearer.

Further details of the project can be found in the paper titled ‘Lenticular Objects: 3D Printed Objects with Lenticular Lens Surfaces That Can Change their Appearance Depending on the Viewpoint’.

The extraordinary minds at MIT have been the source of several 3D printing innovations over the years. Just this month, researchers at the university developed a new method of invisibly embedding information into physical objects using 3D printing technology. The concept is named ‘InfraredTags’ and it’s all about embedding IR-readable barcodes and QR codes within the interiors of 3D printed parts. Visible only to dedicated IR sensors, these tags are designed to be invisible to the naked eye.

MIT researchers have also developed a method of 3D printing objects that can sense user interaction. The novelty is that the objects are 3D printed from a single piece of material (or metamaterial, more precisely), with electrode sensors integrated into the material structure itself. As such, the printed structures are able to detect various changes in state, including applied forces and rotations.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a kettlebell with a 3D printed surface that tells the user how to hold it properly. Image via MIT.