Mimaki Engineering, a Japanese inkjet printer manufacturer, has joined MIT’s Center for Additive and Digital Advanced Production Technologies (ADAPT) as a founding member.

Yasuhiro Haba, Mimaki’s Executive General Manager of Sales Division, said, “Working towards ADAPT’s vision for the amalgamation and evolution of AM technology and digital production, Mimaki will continue to contribute to ADAPT activities through our inkjet technology and mass customization printing solutions.”

Mimaki’s full-color inkjet 3D printing

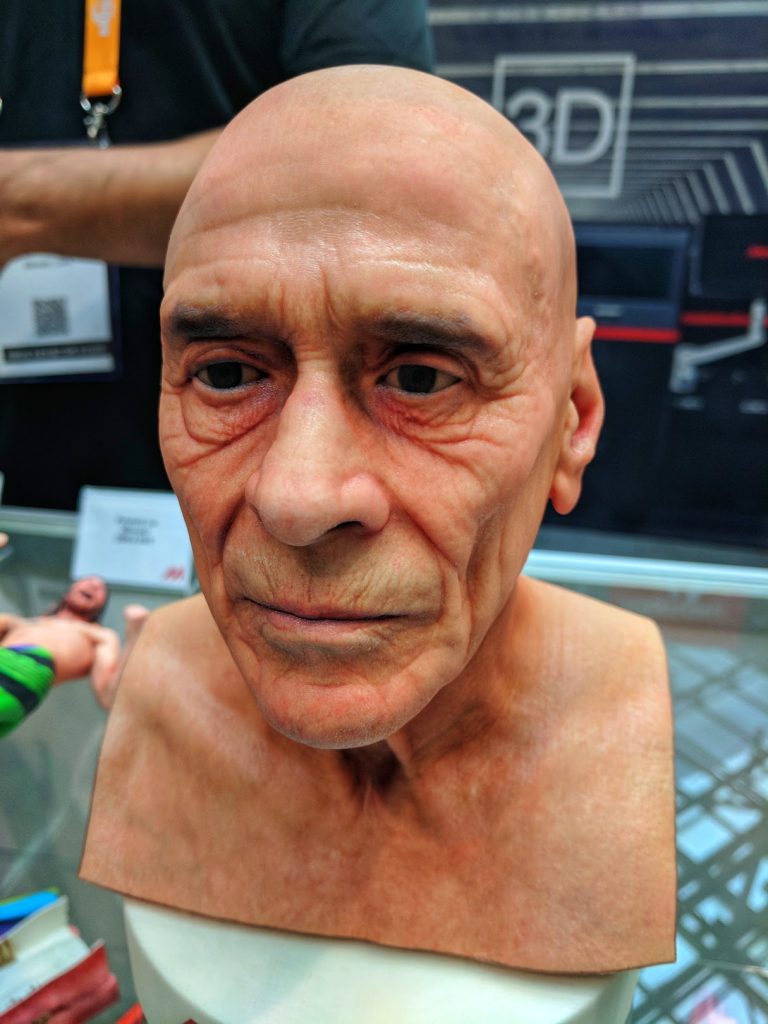

In the additive world, Mimaki is known for the 3DUJ-553 full-color UV inkjet 3D printer, capable of more than 10 million colors.

One of the clients of Mimaki, JMC Corporation, a Japanese CT scan specialist uses the 3DUJ-553 to 3D print color parts of human anatomy for use in the medical sector.

Mimaki’s customers have reported high quality of color parts made in the 3DUJ-553. Popls Inc., a Japanese printing company, used plaster based 3D printing before acquiring the 3DUJ-553 to supply its customers in the comic market.

Miki Nakazawa, Executive Vice President of Popls Inc, said, “Using Mimaki’s 3DUJ-553 printer, we were able to show our customers that 3D print has evolved […] Compared with this, our past work seems to be faded.”

On joining the ADAPT center, Mimaki installed the 3DUJ-553, and UJF-7151 plus, a large-format inkjet printer, at the MIT.

Haba said, “Mimaki will utilize the feedback gained through ADAPT activities to help with future product development. We are honored to be selected as one of the founding members of MIT’s ADAPT.”

The ADAPT center

The ADAPT consortium was announced by Professor John Hart at this year’s formnext in Frankfurt. Professor Hart is a renowned mechanical engineer, known for creating the high-speed FDM printer FastFFF and cellulose-based filament.

The consortium brings professionals from various disciplines, including mechanical engineering, materials science, and business to develop additive manufacturing. The Center also holds research symposiums on additive manufacturing and a members-only annual workshop.

In addition to the above-mentioned efforts, ADAPT also runs a certified online course on additive manufacturing. The 11-week course takes a student from the basics of AM vocabulary to the preparation of parts for 3D printing, and AM product viability analysis.

Mimaki is among the twelve members to join the ADAPT center so far. Other members include the automotive manufacturer General Motors, British metal 3D printer manufacturer, Renishaw, and German 3D printer maker EOS.

These members contribute funds to ADAPT that are used to further research on additive manufacturing.

Nominations for 3D Printing Industry Awards 2019 are open. Let us know about the industrial and professional leaders in the additive manufacturing industry.

For more news on 3D printing subscribe to our 3D printing newsletter. You can also visit us on Facebook and Twitter.

If you are looking for a job in the industry, then please visit 3D Printing Jobs.

Featured image shows Akira Ikeda, Mimaki Engineering Chairman, and Professor John Hart of the MIT. Image via Mimaki