UK metal powder producer Metalysis has given an update on the progress of its ongoing aluminum-scandium alloy R&D program. Launched to fulfill material demand in core value scandium sectors, such as advanced and additive manufacturing, the project is now in its second year.

According to the official program update, the past 12 months have “affirmed the view that Metalysis’ process could address challenges that have historically restricted the industrial use of scandium despite its excellent properties.”

Furthermore, “High value AlSc alloy continues to pose excellent launch product potential for Metalysis’ Generation 4 industrial plant.”

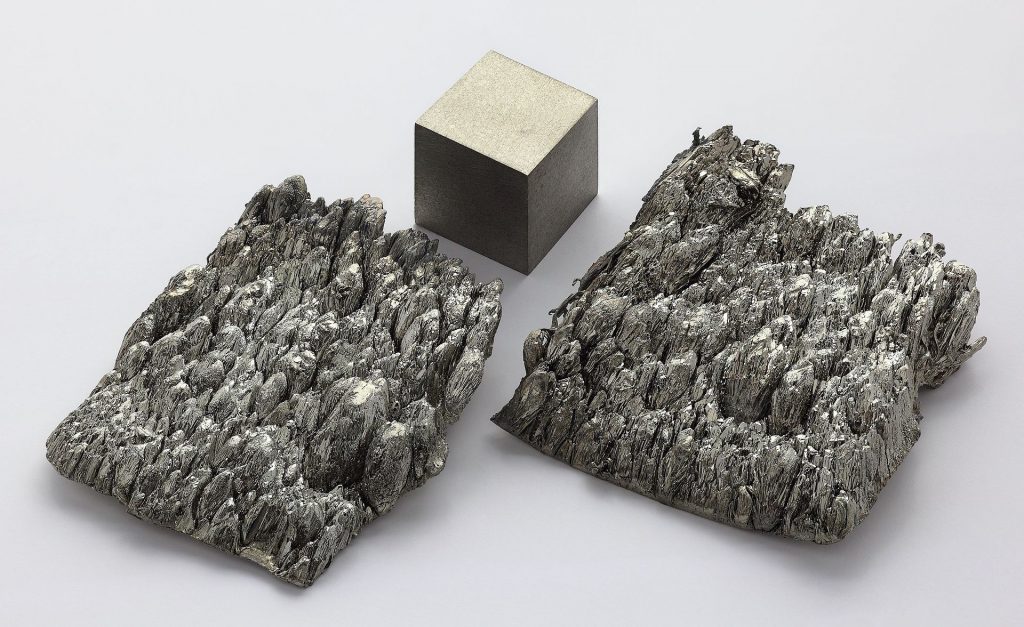

Why scandium?

With a high strength to weight ratio, AlSc alloy is a material that presents great potential to aerospace and automotive applications. Through subsidiary APWorks, leading aerospace company Airbus has in fact created its own aluminum-scandium alloy (Scalmalloy) which contains magnesium, and is piopularly showcased in the Lightrider motorcycle.

But, as a material short in supply, there remains a heightened demand for scandium alloys, especially those compatible with specialist processes like additive manufacturing.

3D printing is the perfect partner for AlSc part production, as it results in little material wastage, and can heighten the alloy’s natural lightness.

Aluminum-scandium progress

Metalysis’ AlSc alloy R&D program was first announced in 2017, at which time the company announced an industrial partner that would be helping to create a scandium-rich master alloy.

In the second half of 2017 (Phase I), Metalysis completed production of an AlSc master alloy, using its patented technology that extracts alloys from an oxide rather than the bulk metal.

A “Generation 1” technology, the master alloy has been initially produced in grams. It is reportedly “more than 15X higher in scandium content than the commonly available 2wt% scandium master alloy” and also, by comparison, made more cost-effectively.

Now in Phase II, the company has begun the process of qualifying scandium oxide as a source for AlSc feedstock, in an effort to “address global production and supply concerns.” Metalysis expects this phase to stretch through the second half od 2018.

Australian Mines partnership

The Australian Mines resource company, concerned with the pursuit of world class scandium assets for the global market, joins Metalysis in Phase II R&D.

Through the flagship Sconi Project, Australin Mines will be providing scandium oxide mined in northern Queensland for feedstock evaluation.

Commercial production of powders

First licensed for production in 2014, Metalysis is now in what it called “Generation 4” production, a stage where its patented Fray, Farthing, Chen (FFC) method has been proven to produce 10s of tonnes of material.

A part of this development, the company opened its Materials Discovery Center in 2017, and has since raised £12 million (approx. $16.07 million) to help the center’s expansion to meet Gen 4 commercialization.

The next stage, “Generation 5,” is distributed production, will focus on 100s – 1,000s tonnes’ production and is scheduled from 2018 onward.

For all materials, hardware and software udpaste subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Sign up to 3D Printing Jobs to post and find new opportunities near you.

Featured image shows Metalysis metal powder sample. Photo via Metalysis.