Metalysis, a UK-based producer of metal powders for 3D printing and other technologies, has announced a partnership for making scandium alloys. The metallic element has positive effects when combined with aluminium, exhibiting high strength to weight ratio favourable in aerospace and automotive applications.

A worldwide demand

The challenge with scandium is that the world only produces around 10 tonnes of the material per year. Demand is about 50% higher than that amount, therefore driving up the cost. And so, in this partnership, Metalysis seeks to “aid in resolving cost constraints encountered in manufacturing aluminium-scandium alloys” through its patented Fray, Farthing, Chen (FFC) technique.

3D Printing Industry learnt more about Metalysis’s powdered metal process at the opening of its specialist Materials Discovery Center. The key difference between FFC and other powdered metal production is that it extracts metal alloys from oxides rather than the expensive metals themselves We also took a closer look at the electrochemical method in an interview with Metalysis metallurgist Dr. Kartik Rao.

Master alloy production

In relation to this partnership Metalysis CEO Dion Vaughan comments,

If Metalysis’ process can contribute to traversing processing issues which pose historic barriers to creating a wider competitive market for aluminium-scandium alloys for 3D printing, it will be a technological breakthrough of revolutionary proportions for our company, our project partner and for end-users.

The company in collaboration with Metalysis has so far chosen to remain anonymous, but the release stipulates that it operates on an international scale. Details of the research & development programme reveal that the companies will work together to create a “scandium-rich feedstock addition, supporting master alloy production.”

Uses of scandium powders

As the specified use of metal powders depends upon the size of its particles, the Metalysis R&D team have confirmed that they will be targeting an aluminium-scandium alloy powder refined for use in 3D printing.

Other scandium powders in use in 3D printing include Scalmalloy®, developed by wholly owned Airbus subsidiary APWorks. An example application of Scalmalloy® can be found in the Lightrider motorbike, as seen at IMTS 2016.

For more of the latest 3D printing materials and other related news sign up to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.

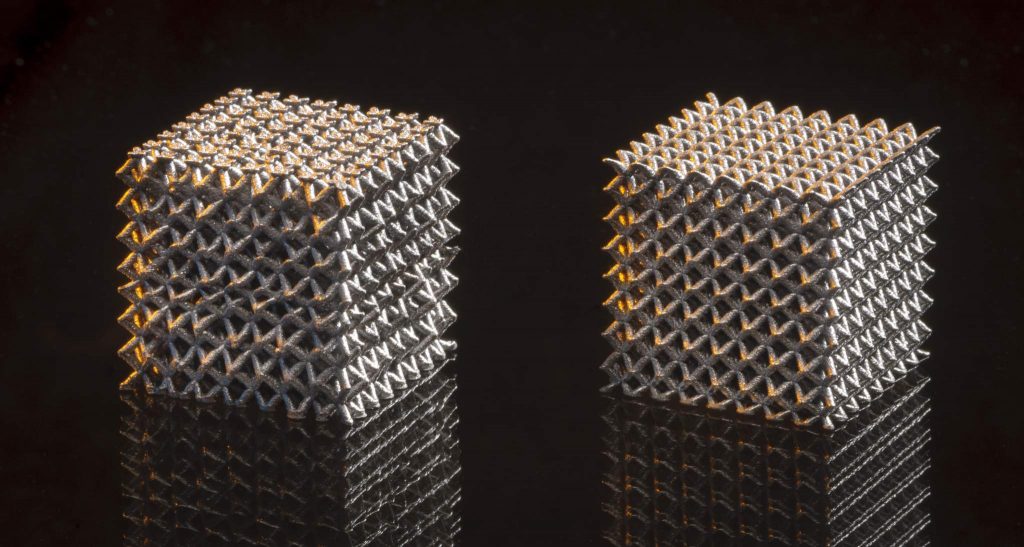

Featured image: Metalysis metal powder. Photo courtesy of the company