Microfabrica Inc. is a truly unique and powerful 3D printing design service that utilizes a proprietary additive manufacturing process called MICA Freeform. MICA Freeform alchemizes typical characteristics of 3D printing,such as the ability to print intricate and unique moving parts with “wafer-scale semiconductor production concepts that enable extreme precision at production volumes.” For companies that depend on miniaturization (medical devices, aerospace instruments, semiconductor prototypes) but want to push beyond the limitations of conventional manufacturing technologies, MICA Freeform could be of interest.

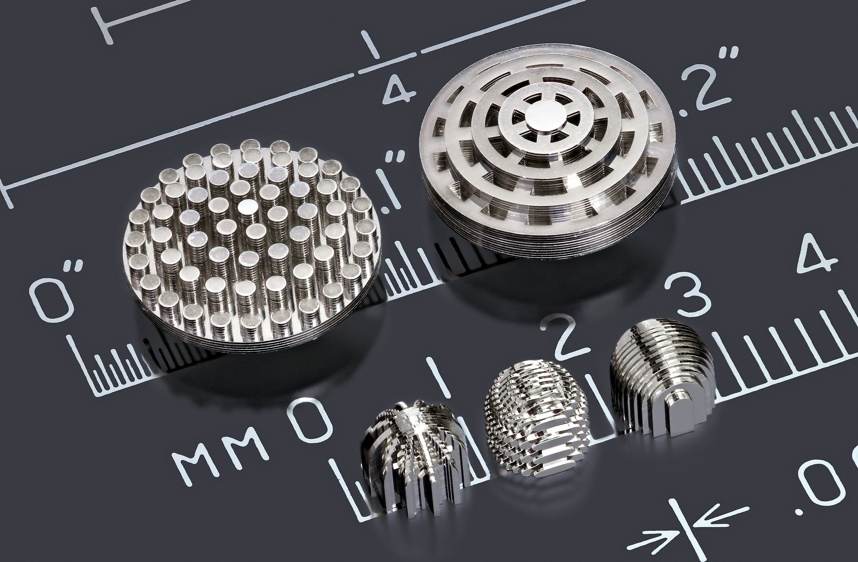

Microfabrica prints millions of metal millimeter scale parts with micron features every year. But what exactly is MICA Freeform 3D printing? We can start to understand what it is by thinking of it as analteration of selective laser melting (SLM), which evolved from selective laser sintering (SLS), and another direct metal 3D printing process, Electron Beam Melting (EBM). SLM was created as a way to improve the mechanical properties of SLS metal, because the metal prints were too often so porous that they required secondary treatments such as infiltration of another metal.

The differences of MICA Freeform and SLM yield an interesting bunch of advantages and disadvantages for using one over the other. To understand them, let’s first understand the main differences in each process.

In the process of MICA Freeform 3D printing, the material is deposited at the atomic level and the 2D shape is created through patterned photoresist, while the thickness is determined by planarization (a process of removing topography from metal and preparing it for electrical connections). Conversely, during the SLM process, the thickness of the printed metal layer depends on the size of the powder layer, as well as the volume change that occurs during the fusion of the powder. MICA Freeform also employs a parallel process of depositing metal over the entire layer, while the SLM process fuses metal region by region, following the path of the laser beam.

Overall, SLM offers a much wider selection of materials and is capable of printing larger parts faster. MICA Freeform is more expensive and requires additional tooling, which can add time to the print process. However, it is better at“producing ultra-precise,net-shape, ready-to-use parts with extremely smooth surfacesand small, well-defined features.” According to Microfabrica’s interesting and numerous whitepapers, the main advantage of MICA Freeform is the ability able to manufacture functional, multicomponent mechanisms, which“obviate the need for assembly.”

For such a complicated internal process, ordering a part or component is just as easy as many other in-house 3D printing services. You send them the CAD model.They process it using their own Layerize software. Thenm you work with their team of engineers to ensure all is well and optimized for the MICA Freeform process, and it is fabricated and delivered. They print objects in valloy-120, palladium, cobalt and copper, which they compare in detail here.