MELD Manufacturing, a 3D printing technology developer based in Christiansburg, Virginia, has teamed up with Virginia Tech to advance its Additive Friction Stir Deposition technology.

Having invented the metal 3D printing process, MELD Manufacturing continues to develop its technology while manufacturing 3D printers based on it. Now, the Yu Research Group from Virginia Tech’s Materials Science and Engineering lab has begun spearheading the study of the technology in an academic capacity.

According to Virginia Tech, its research interests include process fundamentals such as temperature, material flow, and distortion, dynamic phase and microstructure evolution, and the design and manufacturing of heterostructured materials. The team also hopes to develop new applications using magnetic materials, metallic glass, and shape-memory materials.

Nanci Hardwick, CEO and Founder of MELD Manufacturing, explains, “We have a primary relationship with the Material Science Department. And they’re so critical for us because they have expertise. They have one of our machines and they have world-class characterization equipment. Because this is a new process, our customers need to know a lot of information about the material that we print, and Virginia Tech is helping us get that information.”

How does Additive Friction Stir Deposition work?

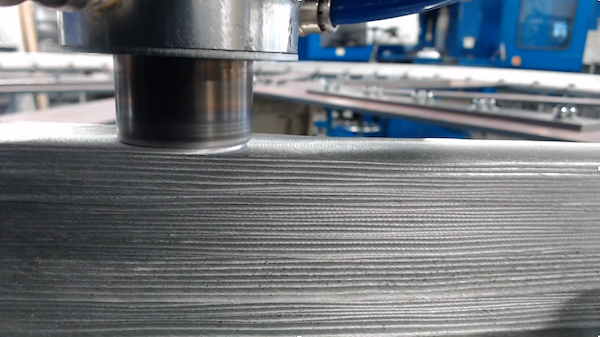

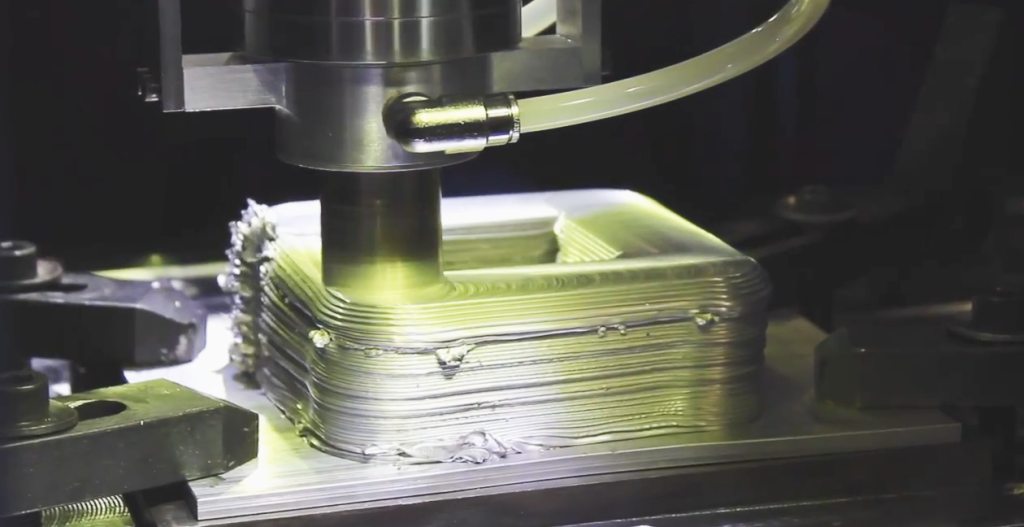

MELD Manufacturing proudly holds over a dozen patents for its Additive Friction Stir Deposition process. Unlike other metal 3D printing technologies, which tend to melt the printing material, the technique is a solid-state process that takes place below melting temperatures.

The technique sees a solid feed rod (the printing material) pushed through a hollow rotating tool. When the feed rod comes into contact with the substrate below, it starts to smear and stick to the substrate via friction, plastically deforming but never melting. The fast-spinning rotating tool has the effect of heating the material, which makes it malleable enough for such severe plastic deformation to take place. Once the first layer is smeared on, the feed rod is simply lifted and pushed back down to print more layers until the final 3D part is complete.

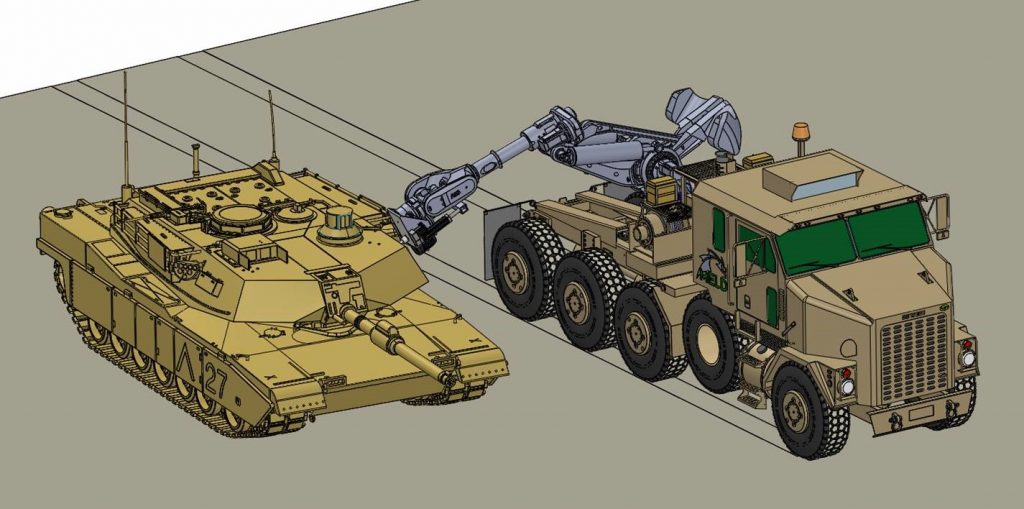

The process is compatible with a wide variety of metals such as aluminum, titanium, steel, and nickel-based superalloys. MELD’s 3D printing applications are predominantly in defense, including part coating, component repair, metal joining, and custom metal matrix composite billets.

Due to its solid-state nature, Additive Friction Stir Deposition benefits from lower residual stresses as well as significantly lower energy requirements when compared to conventional laser-based 3D printing. It’s also compatible with materials that aren’t susceptible to porosity, hot-cracking, and other problems associated with melt-based technologies.

Additionally, MELD’s technology is a single-step process, so users don’t have to worry about tedious post-processing workflows like sintering or hot isostatic pressing (HIP) to improve part quality.

Combining size and speed

According to MELD, Additive Friction Stir Deposition is capable of producing large metal parts at scales never seen before. This can be attributed to the fact that the technology is not limited to small powder beds or vacuum systems, it’s an open-atmosphere process that’s not restricted by operating environments or material surface conditions. MELD also claims that the technique can deposit material over ten times faster than a process like powder bed fusion.

Hardwick adds, “We’re able to make big things, parts that previously could only be forged. We’re able to make them and alloys just not possible to print with using other 3D printing technologies. And we’re able to make them in open air which takes any limitation on scale off the table. This is an incredibly scalable technology.”

Additive Friction Stir Deposition is just one of many 3D printing processes that have been unveiled in recent years. Just this week, Barcelona-based BCN3D announced its new Viscous Lithography Manufacturing (VLM) 3D printing technology, marking the company’s entry into the resin market. The approach is a multi-material one, enabling users to print with two highly viscous resins at once.

Elsewhere, a consortium including Airbus, Safran Landing Systems, and the National Manufacturing Institute Scotland (NMIS) recently started working on a new hybrid directed energy deposition (DED) 3D printing process for the aerospace sector. Aiming to overcome the challenges that conventional manufacturing firms currently face, the new technology will reportedly address a number of issues related to manufacturing costs and lead times.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the patented MELD solid-state process in action. Photo via MELD Manufacturing.