Digital manufacturing is increasingly discussed with reference to the 3D printing industry. Companies operating in advanced sectors have taken action in combining additive manufacturing processes within Industry 4.0.

However, a recent survey published by McKinsey & Company, a New York-based management consulting firm, suggests that few have yet to successfully adopt digital manufacturing processes.

“Despite this focus and enthusiasm, companies are experiencing ‘pilot purgatory’ – they have significant activities underway. But they are not seeing meaningful bottom-line results,” said Richard Kelly, a McKinsey partner.

Innovation with Industry 4.0

From the recently developed automated FlexiFinish post-processing system from the MTC, to digital supply chains for 3D printers developed by INTAMSYS, the digitization of manufacturing processes, also known as Industry 4.0, is a recurring trend across the 3D printing industry.

Thus, to fully understand how manufacturers across the globe are approaching digital manufacturing transformation, McKinsey & Company, with over 90 years of experience advising businesses, governments, and institutions, has released its fourth 2018 Manufacturing Global Expert Survey.

This survey consisted of 700 companies across seven countries – Brazil, China, France, Germany, India, Japan, and the USA. All companies surveyed had a minimum of 50 employees and $10 million in annual revenue.

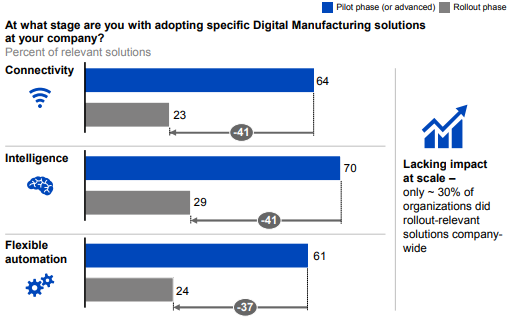

The survey also breaks down Industry 4.0 pursuits into three areas; Connectivity, where companies use digital performance management and augmented reality within standard operating procedures.

Intelligence, which covers advanced analytics and artificial intelligence (AI) used in decision making, i.e. digital quality management and AI-driven demand forecasting. The third area includes flexible automation, which covers new robotic technologies that improve productivity.

Trial to adoption gap

As stated by the Manufacturing Global Expert Survey, 92% of respondents believe that they lead or are on par with competitors in Industry 4.0 manufacturing strategies with the majority already piloting digital manufacturing solutions.

Nevertheless, most of the manufacturing companies reported challenges when attempting to advance beyond the pilot phase.

As seen from the graph above, the gap between piloting and rollout is large. Although companies report significant numbers of pilots, most indicate less progress in terms of broader rollout.

“The challenge is to roll out successful pilot projects to the entire organization. That’s what makes transformation happen,” added Kelly.

In addition, a June report from McKinsey Global Institute (MGI), the research arm of Mckinsey & Company found that AI adoption is slow; with only 20% of “AI-aware” businesses claiming its adoption.

Escaping pilot purgatory

Despite the lack of recorded successful digitized manufacturing solutions, the survey found that two-thirds of respondents rank digitizing the production value chain as a top priority.

“It is quite possible companies still believe in the potential of the various technologies of Industry 4.0,” said Kelly.

“But many are less hopeful about their individual chances of reaping benefits at scale. But we’re seeing great success in the number pilot projects being launched, and the general attitude toward digital manufacturing is quite positive.”

As a result of its findings, the survey concludes with suggestions for businesses to effectively test and adopt digitized manufacturing solutions. This includes establishing a clear and complete vision for an innovative digital process. The survey states:

“Look down the road – i.e., past an immediate fix – and beyond your company – i.e., into the context of the entire ecosystem – and make technology decisions based on what will build a long-term competitive advantage.”

Stay updated with the latest 3D printing news by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Seeking a career change or looking for new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the digitization of manufacturing processes. Image via Mckinsey & Company.