McDonald’s has reportedly reinvented the straw using 3D printing as a prototyping tool. The device is termed STRAW (Suction Tube for Reverse Axial Withdrawal). According to the PR around the “news” the STRAW has been engineered to accommodate McDonald’s new milkshake, the Chocolate Shamrock Shake.

Designed by JACE Design and NK Labs, the straw will be given out for free in over 80 McDonald’s locations within the next few weeks. Although the fast food chain will reportedly only have 2000 to giveaway initially, according to Fast Code Design, McDonald’s may push the design into mass production.

3D printed marketing

To create this straw, the designers made a number of different designs using 3D printing and other techniques. The iterated designs were then tested to refine the flow of liquids through them. While of course 3D printing is a very useful tool for prototyping and iterating designs, this news also demonstrates the trend of brand’s using 3D printing as a marketing tool. We’ve seen this recently with British company Majestic 3D printing the internet in space and Disney using 3D printing to promote the new Star Wars film, Rogue One.

Milkshake marketing

While you may think there is nothing wrong with the current straw design, the conventional straw that is used globally, you probably haven’t tried McDonald’s new product. What better way to market a new milkshake than redesigning the straw with 3D printing.

The Chocolate Shamrock Shake features a mixture of chocolate milkshake and the Shamrock Shake. The shake therefore, has two different levels of thickness. In order to address this, McDonald’s obviously needed to create a new drinking straw.

Over-engineering

Ignoring the obvious marketing attempt that pokes fun at the slick campaigns of companies like Apple. This project demonstrates the use of 3D printing as a prototyping tool. In order to over-engineer the STRAW, the global fast food chain required 3D printing.

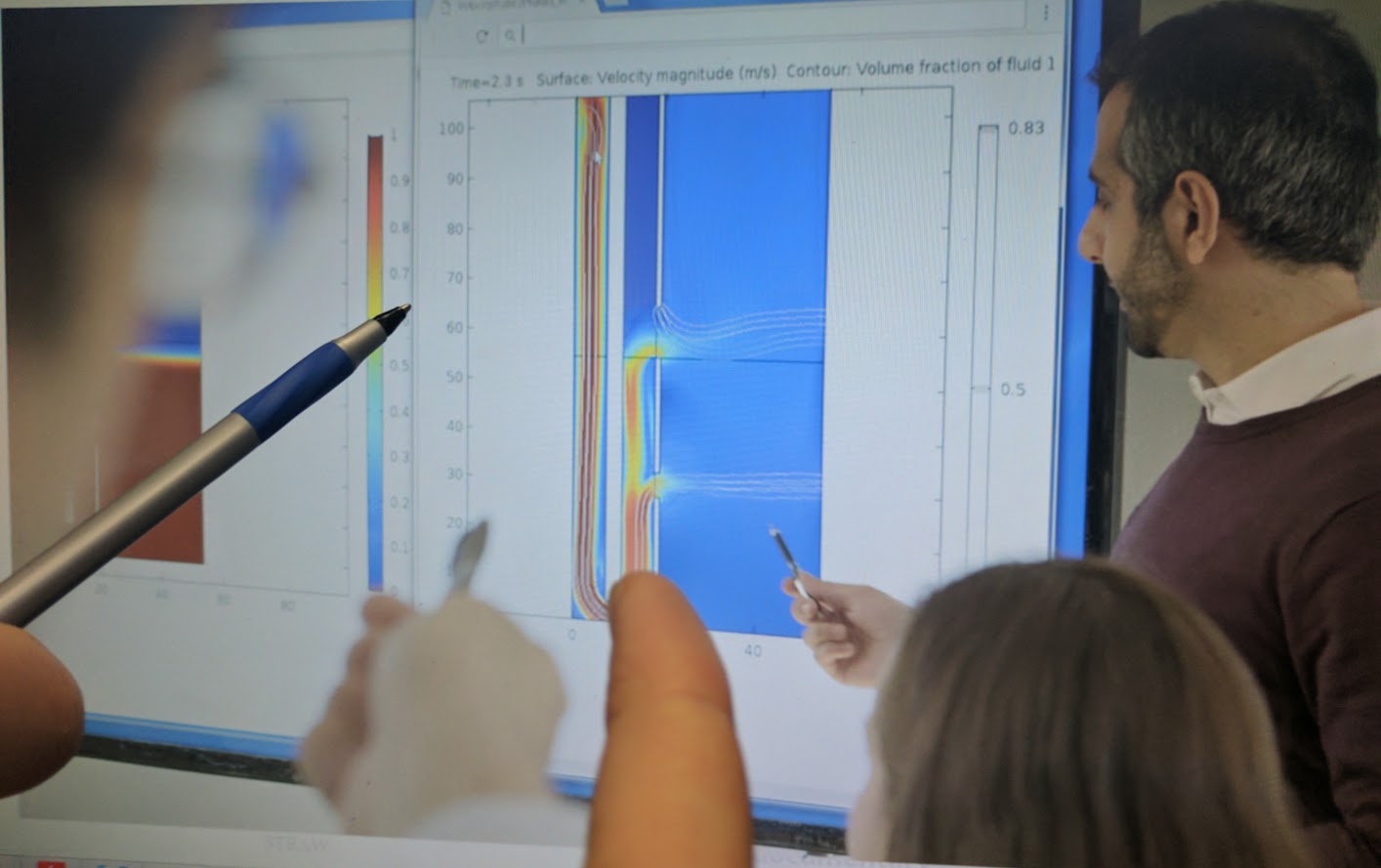

Creating the device, the designers had to evaluate the flow of liquids through the plastic tubes. A more serious application of similar science can be seen in an area 3D Printing Industry often cover, microfluidics. Recently Cranfield University research looked at the use of 3D printing for creating devices to assess the flow of liquids.

Similarly, researchers in California have used 3D printing in order to create Lego bricks that facilitate microfluidics research.

J -shaped design

The new STRAW is j-shaped with a number of additional holes than your standard boring plastic tube. The design allows the user to taste both flavors of the Chocolate Shamrock shake simultaneously. With holes at the bottom and sides of the J-shaped tube, the straw facilitates consumption of viscous milkshakes with ease.

Originally reported in Fast Code Design.

Featured image shows the STRAW. Image via McDonald’s.