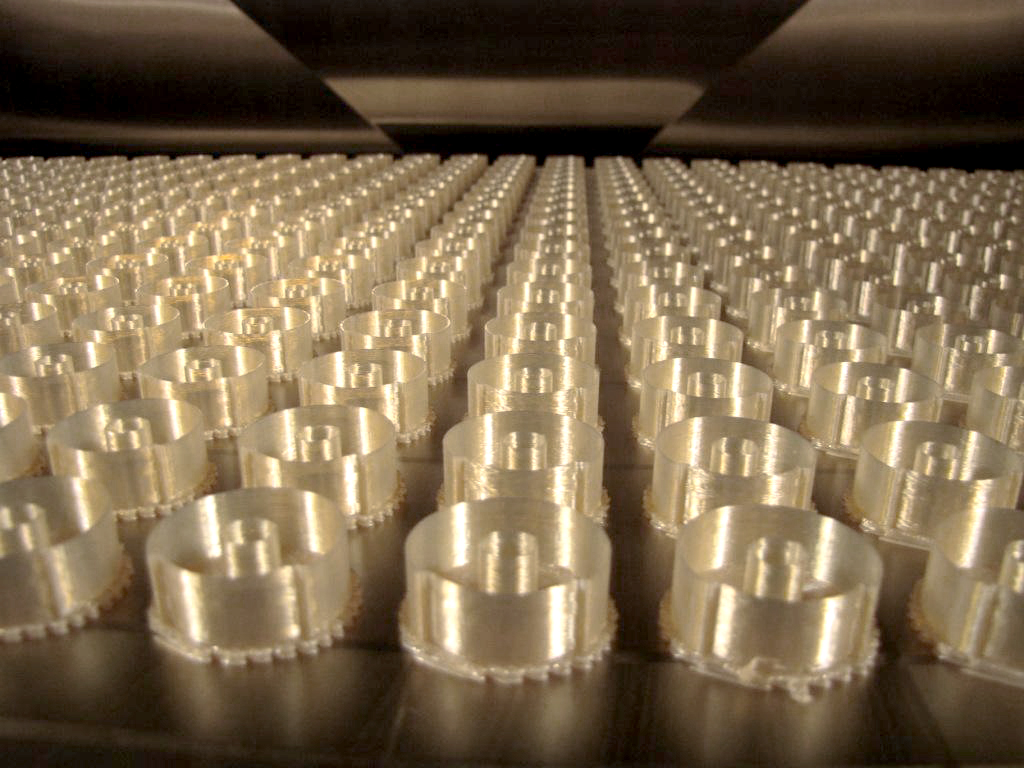

Although many are fascinated by its i.materialise consumer division, Materialise is one the largest 3D printing services in the world, with over 100 professional and industrial grade 3D printers on its premises in Leuven, Belgium. This means that it has already created the concept that many other manufacturers are still trying to set up: a full additive manufacturing factory. Now, that factory is certified to make airplanes.

Since Materialise’s internal 3D printing capabilities are still limited to plastic materials, the EN9100 and EASA 21G certifications it has obtained pertain only to plastic parts (which include Stratasys’ ABS and Ultem filament, as well as EOS nylons for laser sintering). However, this can also very likely be considered as another step toward implementation of internal direct metal 3D printing.

“We at Materialise have enjoyed a long collaboration with the aerospace industry as providers of high-quality prototypes, production tools and cutting-edge software,” Jurgen Laudus, Director of Materialise’s Factory for 3D Printing, stated. “We have also recognized the growing demand for the manufacturing of end-use parts that are ready to take to the skies,” He continued, “By obtaining these certifications, we are ready to fulfil this demand by additively manufacturing functional end-use parts for partners throughout the sector in order to improve the overall performance of their aircraft.”

The EN9100 is a certification of quality assurance for the Aeronautic and Aerospace sector, while EASA Part 21G means Materialise is certified to be able to deliver parts with a Form 1 certification (no ties with Formlabs’ desktop 3D printer), implying that the parts are “ready to fly”. After consolidating its role as a leading supplier of medical 3D printed models, Materialise is, thus, aggressively going after the aerospace sector, which is proving to be one of the industries with the greatest appetite for 3D printed parts.

This is because 3D printing allows for manufacturing of end use parts which can help aeronautic and aerospace companies significantly reduce the weight and the operating costs of an aircraft. Furthermore, these results are obtained without sacrificing safety, improving both fuel efficiency and performance. It is a win-win situation for everyone involved and, as a result, it is likely going to grow a lot in the years to come. Materialise is counting on that trend for its 3D printing business to really take off.