Belgian 3D printing software developer and service provider Materialise has announced the addition of native CAD workflow functionality to its Magics platform.

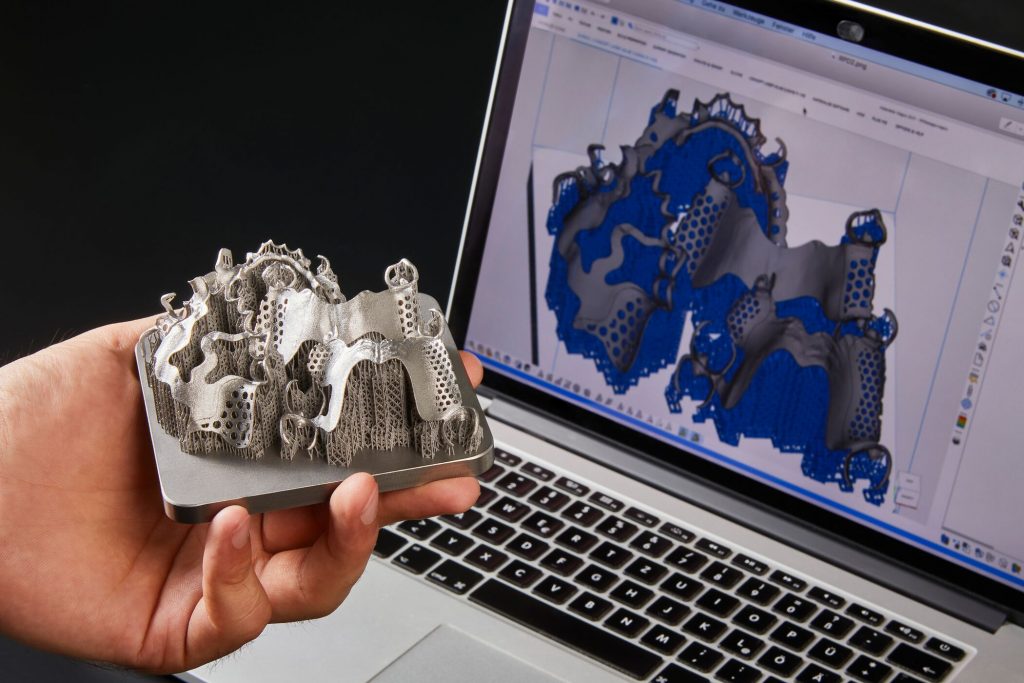

With the integration of Siemens’ Parasolid software, Magics users will soon be able to switch seamlessly between CAD and mesh workflows, and continue iterating upon designs without having to leave the program. According to Materialise, this upgrade could also enable adopters to better prepare parts for 3D printing, upping their productivity, while yielding “more accurate and fit-for-purpose build data.”

“For years, the 3D printing industry has discussed whether CAD or mesh is the preferred workflow for file preparation,” explained Stefaan Motte, Materialise’s Vice President of Software. “We believe both offer unique benefits and a seamless integration of both formats will provide users with the optimal workflow.”

Materialise’s modular offering

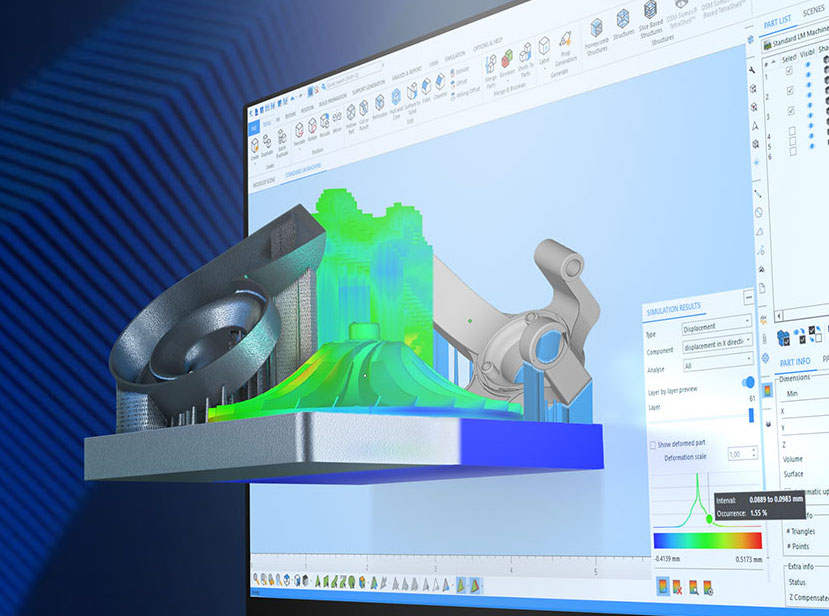

While Magics is nominally Materialise’s proprietary build preparation software, it offers far more than just slicing functionality, providing users with a streamlined end-to-end workflow, from importing design files right through to end-reports.

Whether users are operating PBF, SLS, MJF, SLA, binder jetting or EBM machines, Magics allows them to repair, edit and even enhance parts, via its auto-fixing and latticing tools. The platform also comes with simplified nesting, automated support generation and built-in analytics utilities, features designed to make it less time-intensive to use, and to allow users to identify defects and avoid aborted prints.

Since launching Magics, Materialise has continually upgraded its software offering, first adding a metal additive simulation module, before launching a dental add-on that’s built to expedite orthodontic printing preparation, and it has now outlined plans to take this to the next level, with the integration of Parasolid next year.

Magics gains another dimension

Developed by Siemens’ Digital Industries Software division, Parasolid is marketed as the world’s leading geometric 3D modeling kernel. Working as part of the company’s broader Xcelerator portfolio, the software provides a range of modeling capabilities, including solid modeling, direct editing and free-form surface/sheet modeling, to those engaged in product design, simulation and manufacturing.

Parasolid now has more than 150 users in sectors ranging from automotive to construction, thus its offering is similarly broad, but its modelling features can generally be broken into designer, editor and communication functions. While the former is designed to enable users to create, manipulate and store demanding models, the latter are meant to facilitate downstream editing, repair and display.

The program also features Siemens’ Convergent Modeling technology, which enables both mesh data and traditional CAD geometries to be mixed within a fully-unified environment. In doing so, the software removes the need for translating data between different formats, a process that can be time-consuming and prone to errors, while allowing users to effectively streamline their manufacturing workflows.

By adding Convergent Modeling technology into Magics, Materialise says that its customers will be able to “benefit from the best of both worlds” moving forwards, and use CAD data to edit part designs before switching to mesh for platform preparation, in a way that allows those engineers more familiar with the former, to edit their parts with greater confidence.

Known as ‘Magics 26,’ Materialise adds that its upgraded platform is set to be released in spring 2022, at which point it will “power additive manufacturing champions with a cohesive and fully-integrated workflow for 3D printing.”

Siemens in the 3D printing industry

While the integration of Parasolid will no doubt be good news for Magics fans, it’s far from the first time that Siemens’ software has been utilized within 3D printing. In June 2021, for instance, car manufacturer Volkswagen announced plans to use the company’s programming to optimize the productivity of its plant in Wolfsburg, where binder jet 3D printing is being deployed within production.

Siemens also expanded its existing partnership with EOS North America earlier this year, with the aim of ramping up the adoption of industrialized 3D printing. As part of the firms’ broadened collaboration, EOS agreed to begin selling Siemens’ software with its machines back in February, providing its customers with a means of achieving greater connectivity between their design and production processes.

Elsewhere, the firm deploys additive manufacturing itself within its Siemens Energy spin-off, which managed to develop a novel digital repair chain earlier this year. The fully-automated workflow enables features, such as intricate cooling channels, to be 3D printed into the tips of gas turbine blades, that reduce their risk of suffering from cracks or defects.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a visualization depicting a 3D printed part being realized on Materialise’s Magics software. Image via Materialise.