The 2021 3D Printing Industry Awards shortlists are now open for voting until the 20th of October. Cast your votes here.

Materialise, a leading 3D printing software developer, has announced the launch of its new Dental Module for Materialise Magics.

The modular add-on is aimed specifically at dental labs, and provides an easy-to-use set of tools to fully optimize and automate the dental 3D printing workflow. Designed to facilitate scalability, the Dental Module streamlines 3D print preparation for common dental applications, covering everything from support generation to build nesting.

“3D printing has become well established within dentistry,” explains Volker Schillen, Market Innovation Manager at Materialise. “Today, many dental labs have their own printers and create custom parts for dental restoration daily. Their next goal is optimizing the workflow so dental specialists can reduce the amount of time spent manually preparing designs to be printed. With automated tools, specialists can instead use this time on other valuable responsibilities, such as meeting with patients.”

Materialise Magics

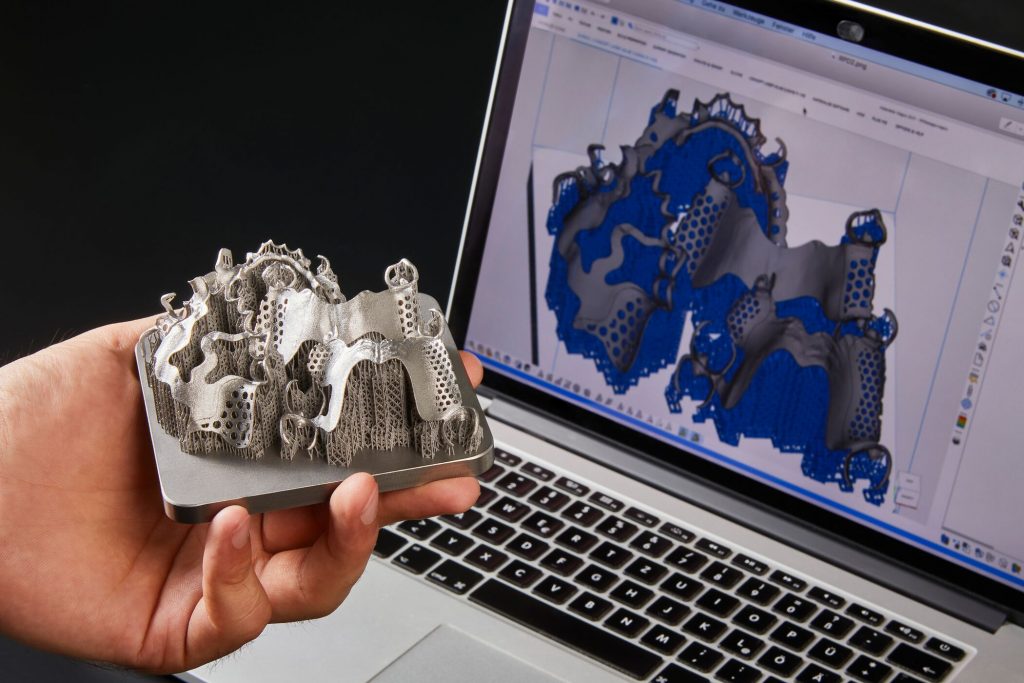

Magics is Materialise’s proprietary 3D print preparation software. Beyond just being a slicer, the program offers a whole host of advanced features that make it the go-to for many manufacturers working with industrial-grade 3D printers.

The software enables users to edit and repair their STL files before processing, ensuring a successful build. Users can also integrate offsets and lattice structures directly in the Magics workspace, reducing the need for dedicated 3D design software. Additionally, Materialise customers can also make use of automatic report generation, build analysis functionality, and automated part orientation and nesting.

With the latest Module launch, there are now ten add-ons available for use with Materialise Magics, all of which help users in industries such as aerospace, automotive, and healthcare with streamlining their 3D printing workflows.

Automating dentistry with the Dental Module

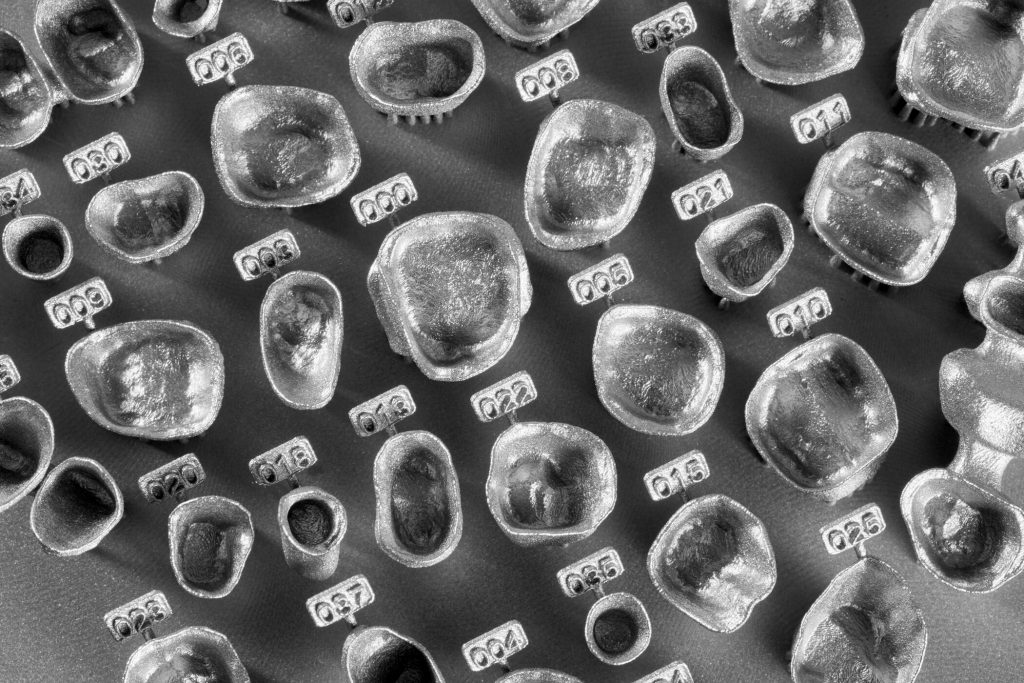

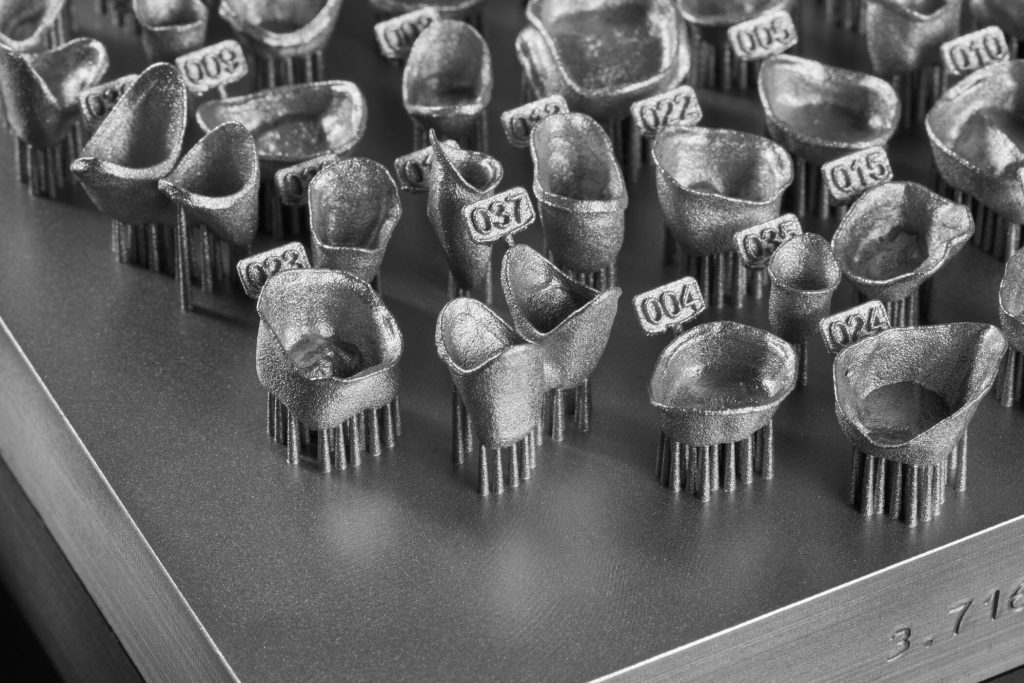

The latest add-on to the Magics platform is the Dental Module. The software tool is designed to offer automatic print preparation for several of the most common dental 3D printing applications, including crowns, bridges, and partial bases.

Once a dental 3D model is uploaded to Magics, the user is only required to click a single button to initiate the module. Once running, the software automates and completes all stages of the pre-printing workflow in a matter of minutes, including labeling, nesting, and support structure generation. If done manually, these tasks can sometimes take hours to get right, depending on the size of the build and the complexity of the parts.

For those that want a little more control over the build process, the Dental Module also allows for customizable processing profiles to be created. Using Materialise Magics’ in-built process modification tools, users can make changes to the automatically generated results or refine the build for niche applications that the Dental Module doesn’t explicitly support.

Targeting another area of the dental AM software market, IBM Watson Health, the healthcare arm of technology consultancy IBM, recently launched the latest version of IBM iConnect Access, the company’s diagnostic and medical image exchange platform. The updated platform reportedly houses the basis of a future 3D printing feature within, whereby users will soon be able to 3D print lifelike anatomical models using patient medical imaging data directly from the platform itself.

Elsewhere, in the dental materials sector, Desktop Metal’s healthcare subsidiary Desktop Health recently launched a chrome cobalt binder jetting material for use in dental applications. Compatible with the company’s Shop System, the dental lab-suitable material is designed for the production of custom bridges, crowns, partial dentures, and surgical guides.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows parts 3D printed with the new Magics Dental Module. Photo via Materialise.