3D printing service provider and software developer Materialise (NASDAQ:MTLS) has, with its over twenty years of experience, found itself immersed in a huge variety of fields. Though, more recently, attention may be drawn more readily to their innovations in the field of medicine, 3D printing bone implants or converting medical imaging data into 3D printable models for surgery preparation, the company is also at work improving industrial manufacturing. Today, Materialise announced the development of a new in-browser, license-free application for creating and ordering custom grippers.

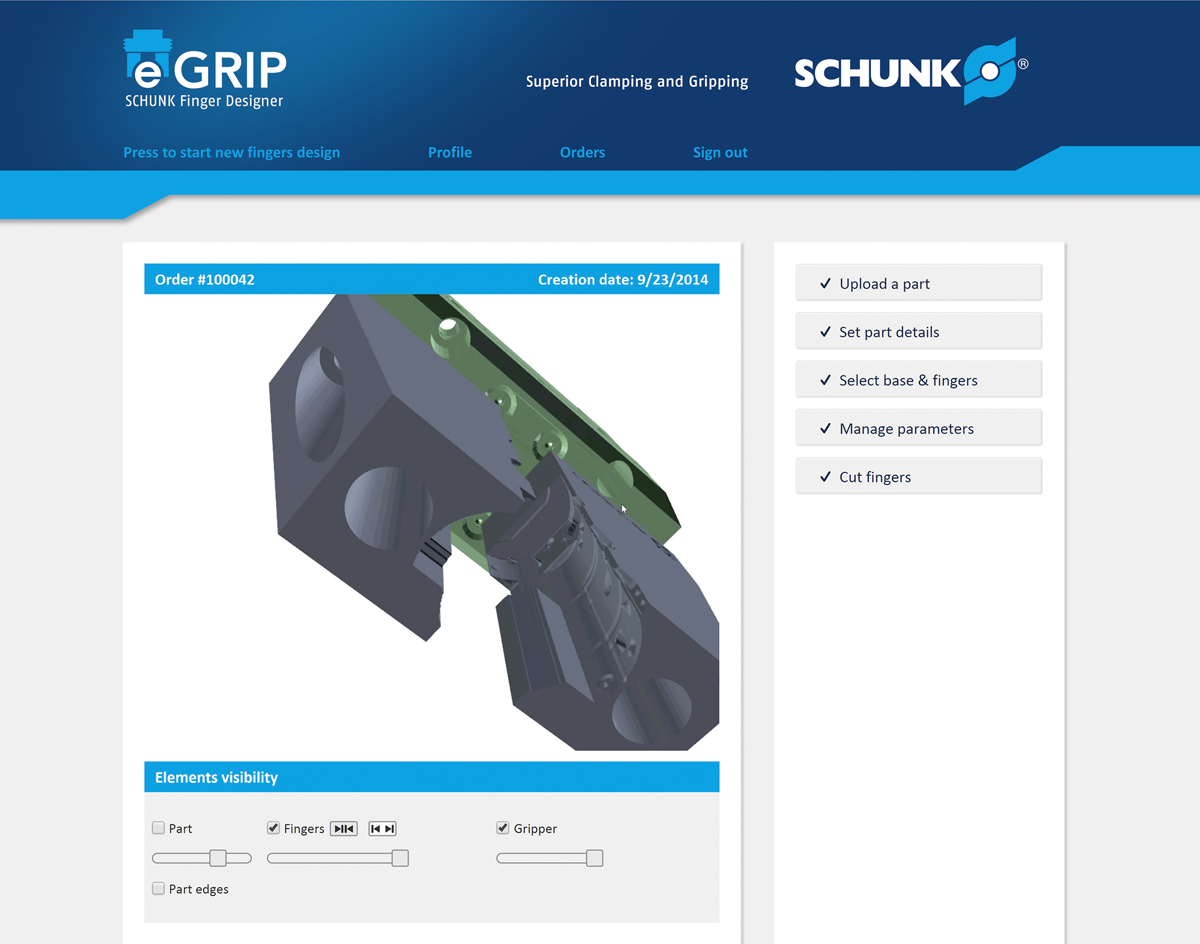

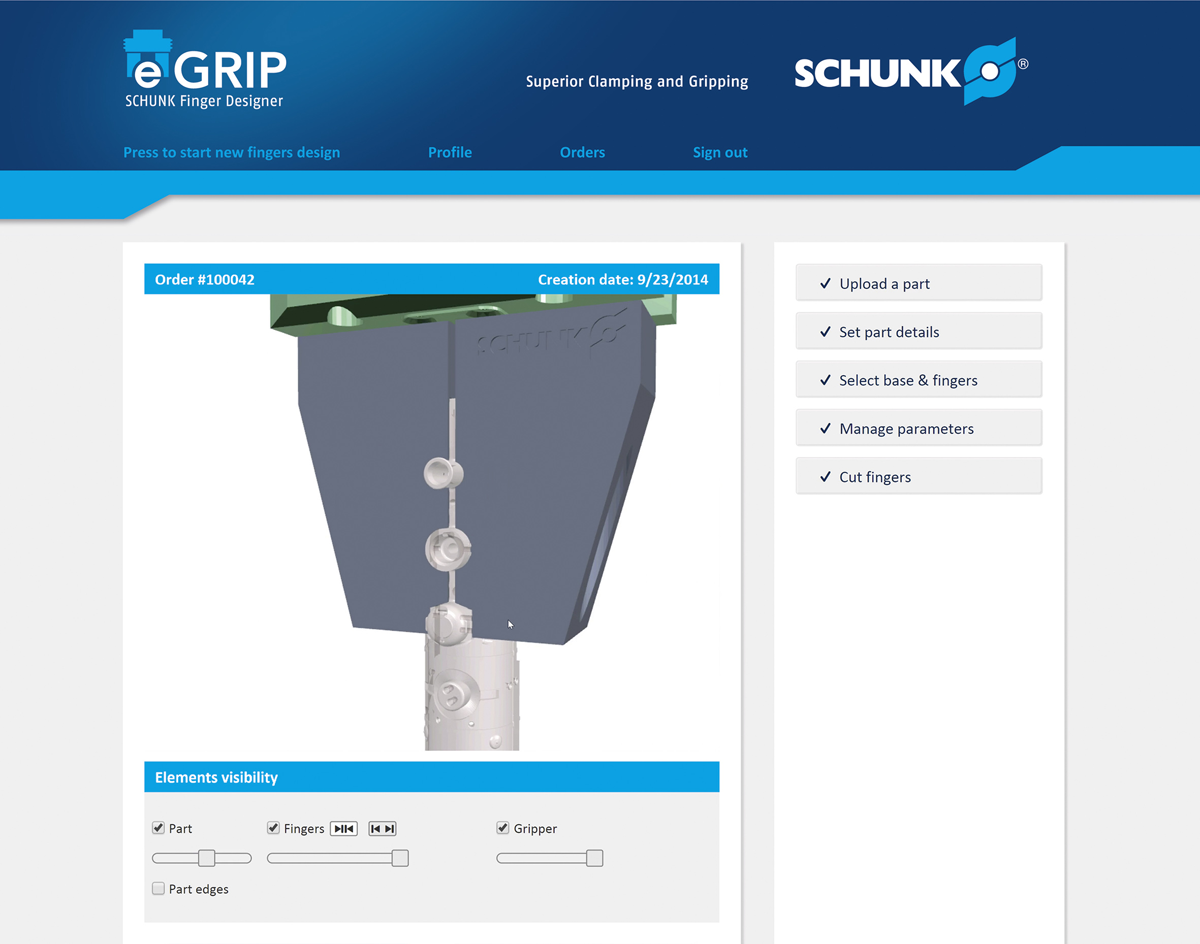

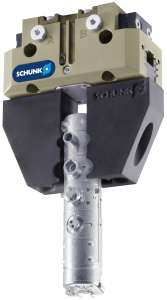

Together with SCHUNK, German manufacturer of gripping and clamping technology, Materialise is currently beta testing SCHUNK eGrip, a free, browser-based program for creating gripper fingers in a few simple steps. Customers can upload the STEP or STL files for a part that will be gripped, as well as relevant data, like the item’s weight, the gripper’s base, mounting direction, and the position of the part to gripper, and the application automatically generates optimally designed gripper fingers. Accompanied by the price and delivery information, the fingers are available for immediate ordering online. The parts are tehn 3D printed in Materialise’s laser sintered polyamide in just a few days through the company’s Streamics 3D printing control and automation software.

SCHUNK’s Head of Product and Portfolio Management Gripping Systems, Marcel Nagel, remearked, “eGrip is a strong example of the innovative ideas you can realize when you combine the core competences of two leaders in their fields – SCHUNK for Gripping and Clamping and Materialise for 3D Printing software and services. The result of our collaboration is the world’s first fully automated design tools for additive manufactured gripper fingers. What’s more, the browser-based, license-free platform also reduces the design and ordering time for customized gripper fingers to just 15 minutes.”

The eGrip software is a much faster manufacturing option, when compared to the weeks it would take to create a similar product through traditional means. There are a growing number of in-browser design programs for ordering 3D printed consumer goods, but, as Materialise, and company’s like it, begin integrating similar 3D printing solutions into industrial manufacturing, the technology will revolutionize the way that all products are made, from individual consumers all the way up to large businesses. Currently in beta, the eGrip application will soon be released to the general public.