Belgian software and service provider Materialise has used its 3D printing and software technologies to support a novel simultaneous double hand and face transplant.

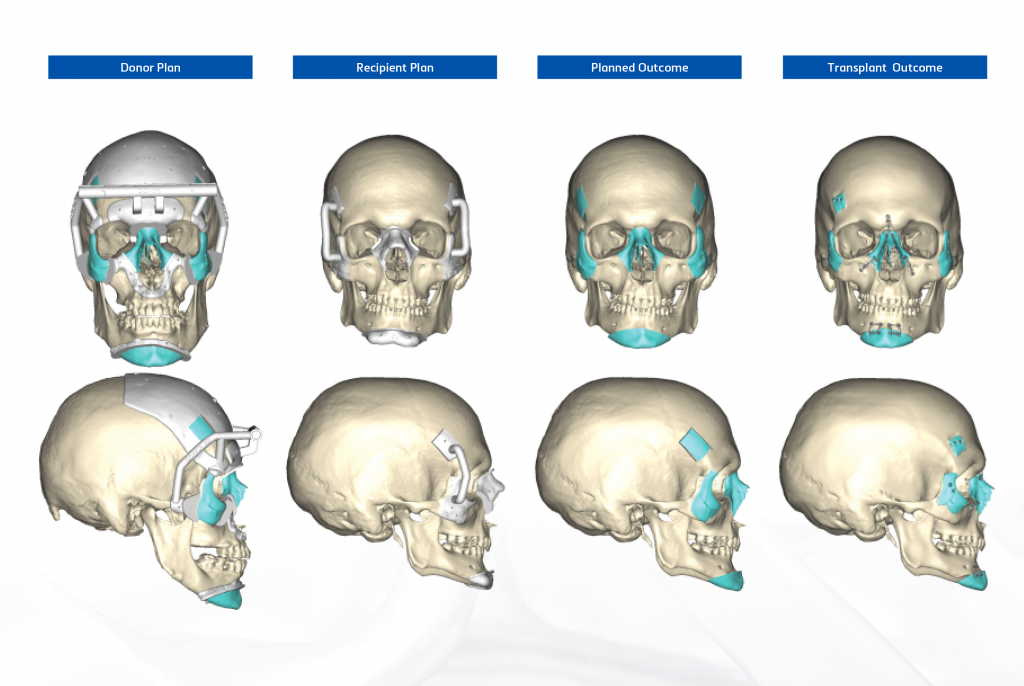

In what’s believed to be a world’s first, surgeons at NYU Langone Health worked with Materialise to develop personalized surgical guides, which enabled them to precisely perform the complex procedure. The medics also utilized the firm’s scanning software to pre-plan the operation, finding that it not only accelerated the treatment, but improved their 22-year-old patient’s chances of survival.

“Complex transplant surgery like this presents new and unique challenges,” said Dr. Eduardo D. Rodriguez, who led the team. “Virtually planning the surgery in 3D and creating 3D printed, patient-specific tools offers additional insights in the preoperative phase, and increased levels of speed and accuracy.”

Materialise’s medical portfolio

As a service bureau, Materialise provides a broad offering to its clients that addresses a range of industries, but recently, the firm has taken a keen interest in 3D printing’s medical applications. The company, which first validated Stratasys’ systems for use in hospitals as long ago as 2018, has now built up a substantial healthcare portfolio.

In addition to supplying medical-grade parts to clients on-demand, Materialise also develops its OrthoView, SurgiCase, Mimics inPrint and PROPLAN CMF software packages. The programs, which allow surgeons to prepare for operations using 3D models, have continually been upgraded, and the Mimics Enlight software gained FDA approval for cardiovascular procedures in June 2019.

Similarly, the company has invested heavily in other medical firms as a means of growing the applications of its technologies. For instance, in 2019, Materialise invested €2.5 million in biotech company Fluidda with the aim of bringing 3D printing to pulmonology, and acquired 75% of Engimplan, to take additive implants to the Brazilian market.

Building on this approach, Materialise has now found yet another new application for its technologies, and worked with a 16-strong team of surgeons based at Langone Health to optimize a world’s first simultaneous transplant procedure.

Additive contributes to a world’s first

In 2019, clinicians working at Langone Health received an in-patient that had been in a car accident. The unnamed male victim had suffered severe burns leaving him with injuries to his face and both arms, and such significant damage to his soft tissue, that it would be difficult for him to live a normal life ever again.

Luckily for him, surgeons based at Langone Health opted to partner with Materialise, to fine-tune a complex transplant that would put him on the road to recovery. Over a period of 14 months, the team used 3D models to develop a surgical plan for the operation, which allowed the medics to visualize the patient’s exact bone structure.

Pre-planning also enabled the clinicians to virtually position different implants over the model, to optimize their anatomical fit. Once the plan was ready, Materialise deployed its 3D printer portfolio to create patient-specific surgical tools such as cutting and drilling guides, that helped the medics position their instruments and accelerate the procedure.

Materialise also 3D printed sterilizable ID tags for nerves and blood vessels, as well as models that were used during donor transport, and splints deployed within tissue reconstruction. According to Bryan Crutchfield, VP and GM of Materialise North America, the firm’s technologies are now becoming a necessity for modern practices.

“Image-based planning and medical 3D printing have completely revolutionized personalized patient care,” said Crutchfield. “As a result, leading hospitals are adopting 3D planning and printing services as part of their medical practices, because they create a level of predictability that would be otherwise impossible to achieve.”

3D printing and surgical success

3D printing surgical guides allows them to be designed for a specific operation, optimizing its chances of success, and the devices are increasingly gaining FDA approval for end-use.

3D printer manufacturer 3D Systems gained 510(k) FDA clearance for its 3D printed maxillofacial surgical guides in October 2020. Made out of the company’s LaserForm Ti and DuraForm ProX PA materials, the devices are designed to be used alongside its Virtual Surgical Planning (VSP) service.

In a more end-use application, surgeons from the Korean Asan Medical Center have deployed a 3D printer to fabricate surgical guides that aid breast tissue retention in cancer patients. During testing, the medics were able to customize the devices to the needs of each individual patient, and optimize their results.

Elsewhere, Australian med-tech company Anatomics has commissioned a study into the benefits of 3D printed surgical guides. The firm found that leveraging its additive “SpineBox” kit, which was used in the operations of 129 patients, it was possible to improve the efficiency and quality of each procedure.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the NYU Langone Health surgeons rehearsing the operation in a lab setting. Photo via Materialise.