Israel-based 3D printer manufacturer Massivit 3D is set to unveil its new Massivit 10000 3D printing system at the JEC World 2022 event in Paris, which runs from May 3-5.

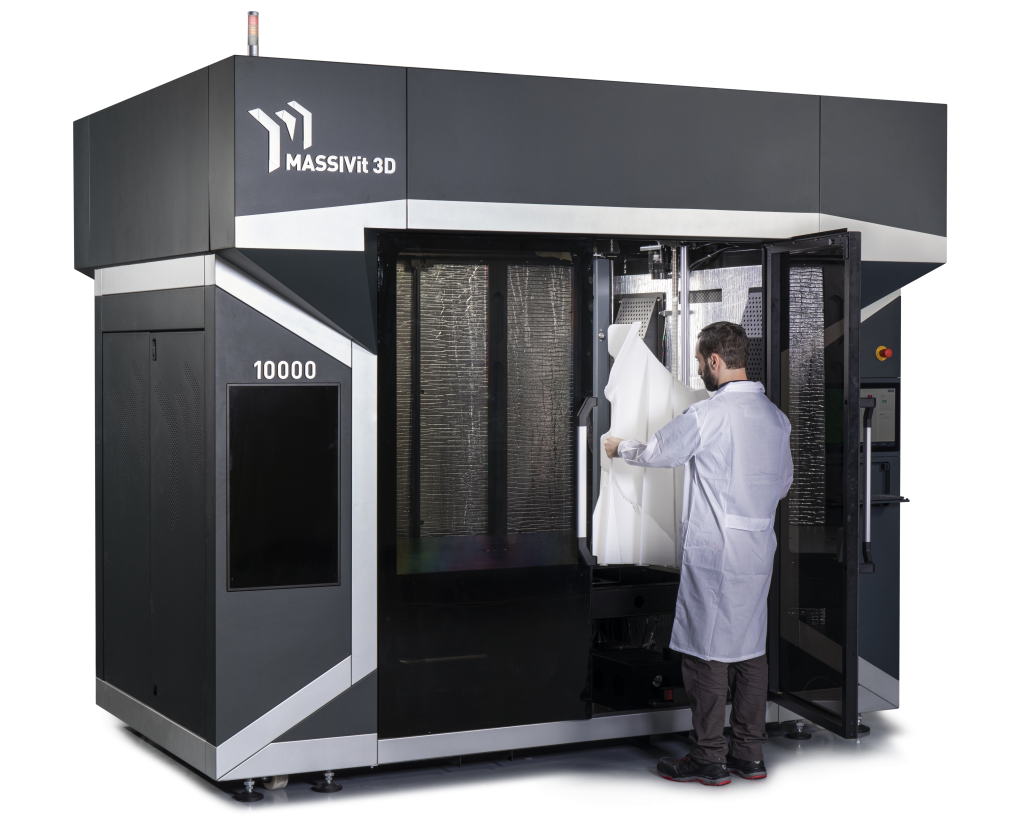

Based on the firm’s next-generation Cast-In-Motion (CIM) technology, the large-format system is designed specifically for printing huge molds made of composite materials. Sporting a whopping build volume of 1200 x 1500 x 1650mm, the printer is Massivit’s largest to date.

The machine aims to streamline and automate many of the steps involved in conventional composites manufacturing, overcoming bottlenecks related to speed, costs, material waste, and the need for manual labor. The Massivit 10000 is reportedly suitable for 3D printing molds, masters, mandrels, and prototypes for sectors such as marine, rail, automotive, defense, aerospace, sporting goods, and furniture.

Erez Zimerman, CEO of Massivit 3D, said, “We eagerly await this momentous occasion, marking a significant company milestone and injecting innovation into the composites manufacturing market. The composites tooling arena has long been held back by antiquated processes and technologies. It’s high time to facilitate digital transformation in this market and we are proud to bring the relevant know-how, expertise, and innovation to the table for that purpose.”

Sizing up 3D printing with Massivit

Founded in 2013 and based in Lod, Israel, Massivit 3D is one of the key players in the large-format 3D printing space. The company made a name for itself with its debut proprietary Gel Dispensing Printing (GDP) technology, which is a cross between FFF and material jetting. The process works by extruding photopolymer gels at high speeds before curing them into solid layers under UV light.

The Massivit product line includes the Massivit 1800, which is available with either one or two printheads. It features a build volume measuring 1450 x 1110 x 1800mm and rapid print speeds of up to 300mm/s.

Last year, the firm also launched its Massivit 5000 3D printer. Primarily aimed at manufacturers and service providers seeking large photopolymer part production for industries such as automotive, marine, and railway, the machine also has a build volume of 1450 x 1110 x 1800mm and a revamped automated print monitoring system.

The Massivit 10000

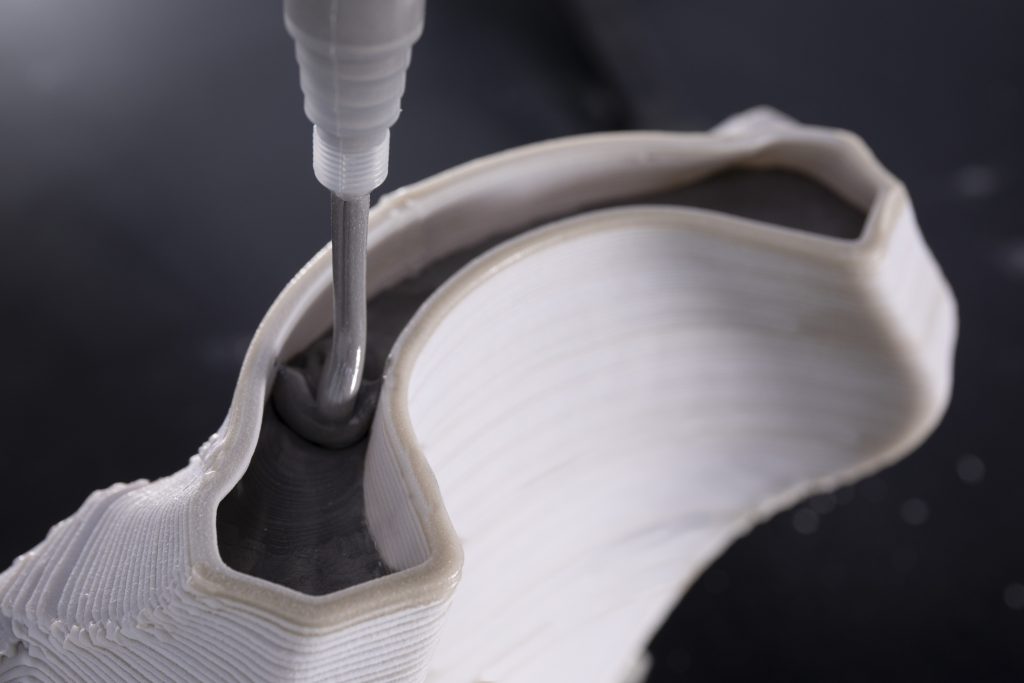

Massivit’s new second-generation Cast-in-Motion process, which is the backbone of the Massivit 10000, is the successor to Gel Dispensing Printing. According to the firm, the technology enables users to shorten their composite tooling production workflows from 19 steps to just four.

So how does it work? A tool pattern is 3D printed using a sacrificial, UV-curable gel. The pattern is then filled using any one of the firm’s thermoset engineering materials, which is chosen based on the desired mechanical and thermal properties. Finally, the 3D printed tool is immersed in water and the sacrificial pattern breaks away, leaving behind a large isotropic mold. By allowing customers to directly print their molds in this manner, it eliminates the need to fabricate an initial plug or master.

The company claims that this process shortens lead times by 80%, slashes labor-related costs by 90%, and significantly reduces inventories and material waste. It also ensures that mold manufacturers are using casting materials with highly predictable properties, a high heat deflection temperature, and a low coefficient of thermal expansion.

Technical specifications and pricing

Below are the currently available technical specifications of the Massivit 10000 3D printer. The system is available to pre-order now with deliveries set to begin in H2 2022. Contact Massivit 3D for a quote.

| Build volume | 1200 x 1500 x 1650mm |

| Printheads | 2 |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Massivit 10000. Photo via Massivit 3D.