The United States Marine Corps is calling for 3D printer training to help its troops respond to military crises.

After introducing an FFF 3D printer to Marine Wing Support Squadron 372 (MWSS-372), Operations Officer Captain Marc Blair has outlined a vision for 21st century innovation in the marines, that will help the land squadron support unit service and maintain vehicles for 3rd Marine Aircraft Wing – the main marine aviation unit of the U.S. west coast.

Handling a Humvee

Following implementation by the 7th Marine Regiment, MWSS-372 has identified 3D printing’s potential to redesign and replace insufficient plastic parts.

In one of the first use cases, MWSS engineers designed a new door handle for a Humvee (High Mobility Multipurpose Wheeled Vehicle) truck.

In development of the handle, the team noted the utility of producing numerous iterations of a design, “We could come up with an idea for something,” explains Chief Warrant Officer Benny Lane, “and we can run through five, six or seven renditions of it in a few days to find the right way to make the product effectively.”

A tool to adapt and respond

3D printers have been installed at military response units all across the U.S. In another project, the Marine Corps are investigating the viability of a mobile Fab Lab (X-FAB “expeditionary fabrication laboratory”).

The U.S. Navy’s Fleet Readiness Center Southeast (FRCSE) based in Jacksonville, Florida, is also credited with 3D printing the force’s first ever aircraft replacement component.

At MWSS the idea is that the technology will create a type of innovation culture within the regiment, encouraging new ideas and methods of problem solving.

“We’d like to see the unit and the Marines receive training, run with their ideas and start producing their ideas,” said Officer Lane, “Then, they can teach other Marines how to use the program so this can continue to help the unit and the Marine Corps as a whole.”

Following the unit’s first experiment, Capt. Blair suggested,

“Marines need to be told here is a tool, here is how to use it, here is some training, and then be allowed wide open left and right lateral limits, and be asked now what can you do with this thing.”

For more of the latest adaptable applications subscribe to the 3D Printing Industry newsletter, followe us on Twitter, and like us on Facebook.

Search for careers and advertise to prospective employees through 3D printing jobs here.

Adjudicate Application of the Year in the 2018 3D Printing Industry Awards. To be in with a chance of attending this year’s event, winning a 3D printer, and having your design 3D printed by Protolabs, enter the 3D Printing Industry Awards trophy design competition.

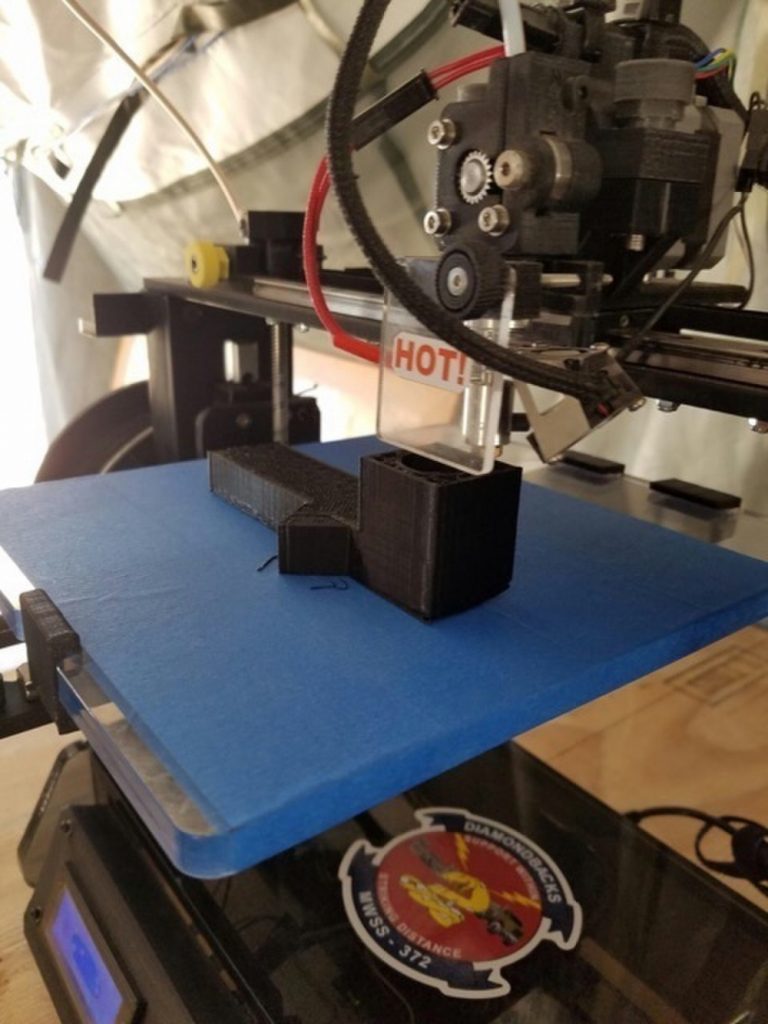

Featured image shows a Humvee (High Mobility Multipurpose Wheeled Vehicle) truck as repaired by 3D printing at MWSS-372. Photo via U.S. Marine Corps