Recently we were contacted by Daniel Brown, a maker from “Down Under”, who successfully started and is currently running a prototyping business, 3D Prototypes and Models, in Adelaide, utilising a desktop 3D printer. His machine array has since grown to three, all desktop and all RepRap systems: Makerbot’s Replicator 2, a Printrbot and a Flashforg Creator Pro; and business is growing fast, with an average of $700 in weekly revenues and peaks as high as $4000 month.

Like other makers around the world he used his engineering and CAD skills to show the people around him the possibilities of working with a 3D printer. He spoke with architects, engineers, Adelaide university teachers and students, and local inventors to show them that they could have a physical representation of whatever they are designing in CAD, all in one place, all in one process. These include inventions, engineering components, rapid prototyping, architectural models, even movie props.

“I found that many immediately understood the possibilities 3D printing offered them, even without resorting to expensive industrial systems,” Daniel explains. “Many inventors and engineers sometime don’t follow through with their ideas because they are afraid to send it abroad to get it prototyped. All they needed was access to a desktop 3D printer to address this issue.”

Daniel explained that in Australia (as probably everywhere else in the world) the large companies – such as those who operate in the mining sector – that require high level industrial prototyping services are likely to have the systems in-house. Those who only need to prototype smaller parts can just as easily turn to a desktop machine. The one requirement being, knowing how to design for 3D printing.

“In Australia, 3D Printing has been quite slow on the uptake, in fact one might say it is as slow as printing itself,” says Daniel. “In March last year, I was saddened to see that literally no-one in my entire state seemed to have a 3D printer so that I could pay them to use to print out my complex, large designs. So I started up this business. Now I spend lots of time just thinking about what I could 3D print that has not been done yet.”

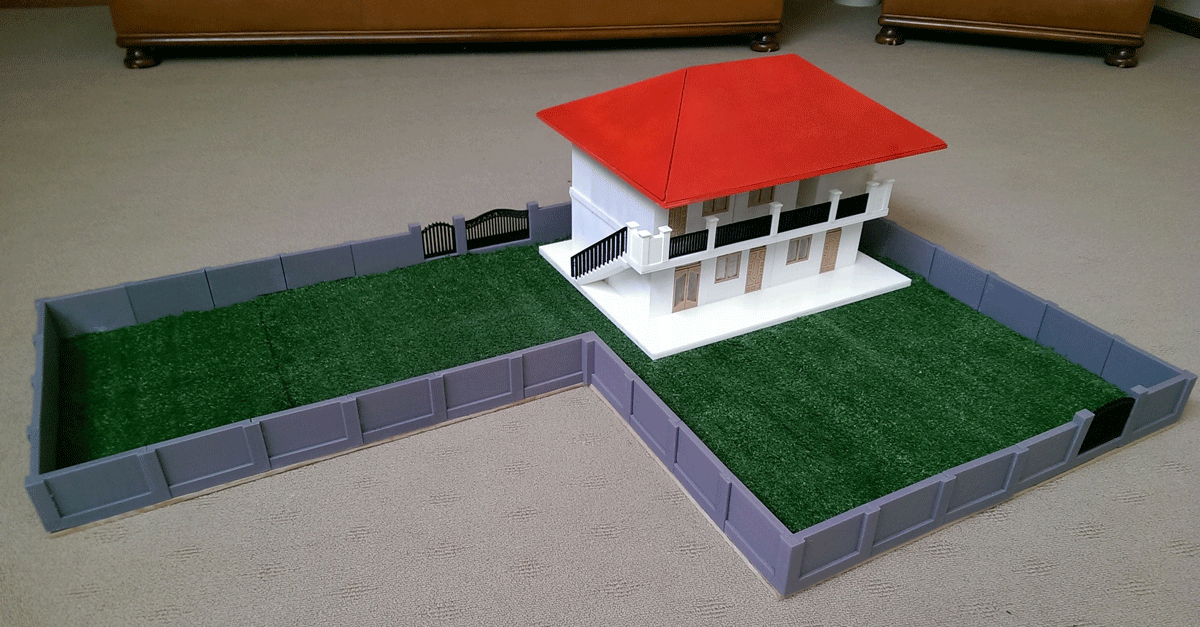

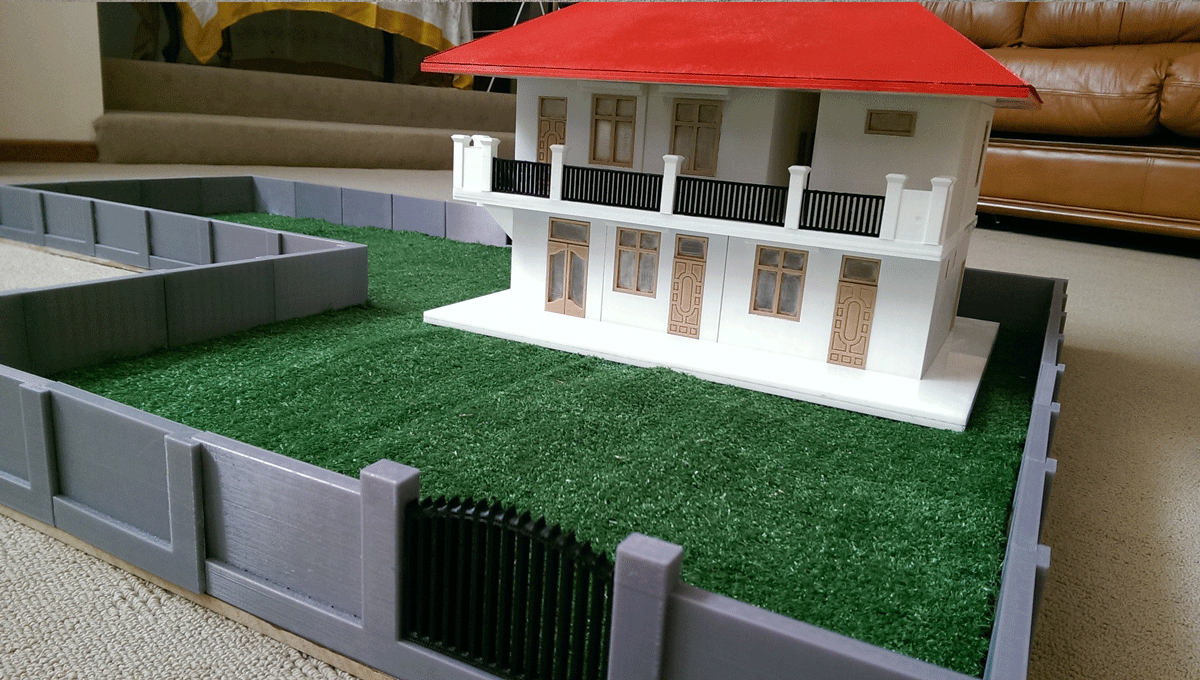

Demand has grown considerably with Daniel receiving as many as 40 job requests a week, even for a large architectural studio. In fact one of the projects he is most proud of is the model for an orphanage to be built in Burma (Myanmar) by a charitable association to allow potential donors to visualise the end goal was. That was done by Daniel, with incredible details (even the doors and windows printed with colorFabb’s woodFill) before he began his prototyping venture, however, he explains, the key is to work with universities and local maker-focused business (such as Makers Empire and Innovation Systems) to spread 3D printing awareness and develop a maker culture, which he does by also teaching courses and giving free consultations to the students.

Many times when I speak with industry “outsiders” about 3D printing, the amazing possibilities it holds for the future and its incredible growth potential, the first thing I hear is “ok, tell me where to put my money and let’s get rich.” Maybe they don’t say it exactly like that but that is, in many cases, the bottom line. People see 3D printing as everything that has come before it: an opportunity to make money.

For some reason, the less one knows about 3D printing and its complexities, the more money they want to put into it, into some part of it, to gain a theoretical competitive advantage and exploit its potential. Unfortunately (or fortunately, depending on your perspective) that is not how it works. For two reasons. One is that although 3D printing is in the very early phase of what could be a decades long growth curve, there are people who have been working with it for almost 30 years and in most cases they are pretty damn good at it, certainly much better than anyone jumping into it now. The other is that it is still a really small market compared to truly mass market and profitable businesses.

Paradoxically, if you want to get rich quick you are better off investing in the food industry, or in smartphones. 3D printing is different. It is more about the enthusiasm of being a pioneer, of seeing up close what the future holds for future generations, and less about the money. This, however, does not at all mean you cannot make money with it. As Daniel’s case shows, you can. You can also make a decent living and the key, as everyone who entered successfully the professional 3D printing arena in these past couple of years, is to grow organically, with the market.

That is what the current industry situation is all about: now you can become a prototyping studio (or launch a new product) with an investment as low as a few thousand dollars/euro. The revolution is that that you no longer need loads of money to start; what you need to succeed is time, ideas and CAD skills.