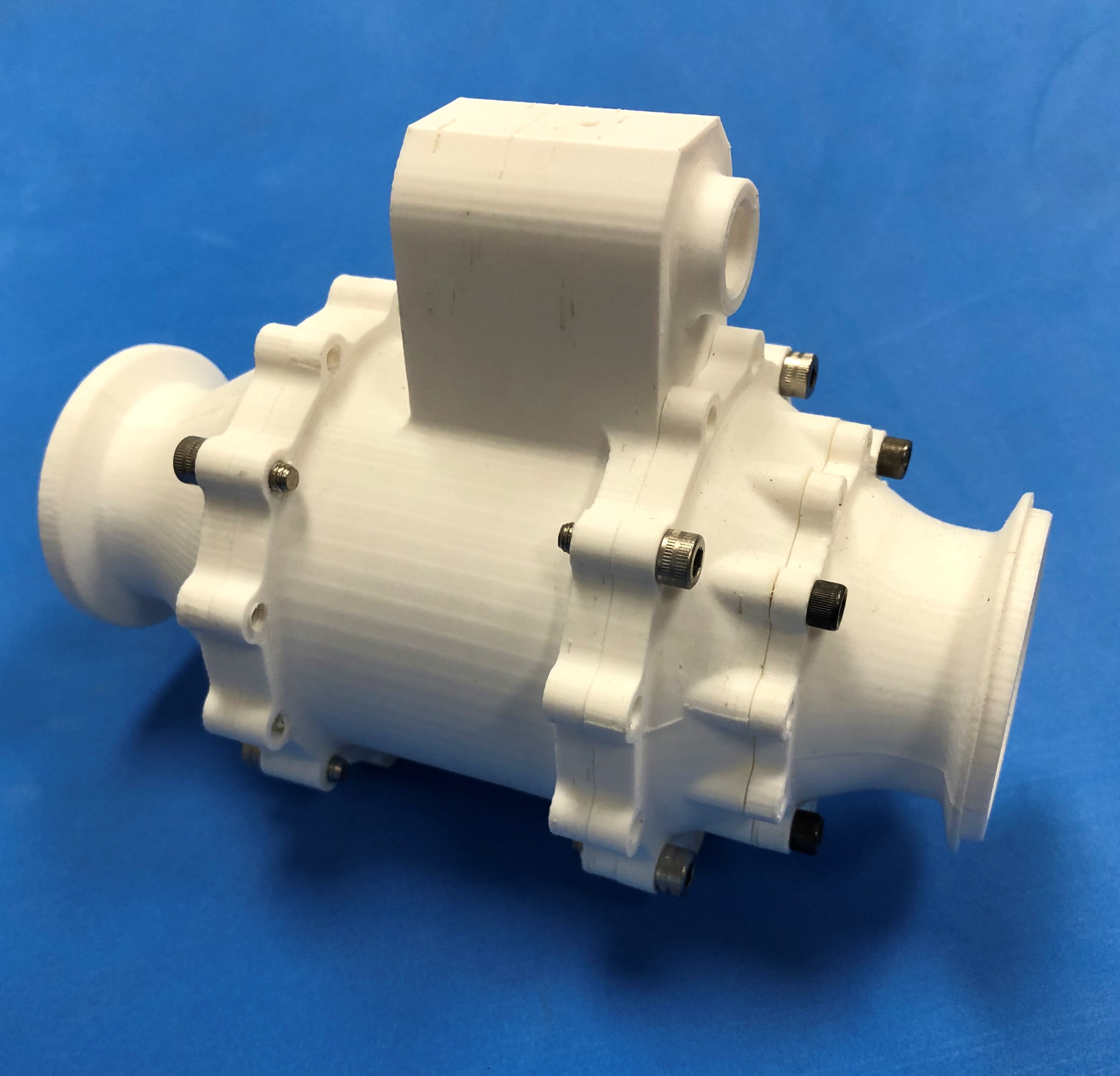

Massachusetts-based rocket propulsion system specialist Triton Space Technologies has used 3D printing to produce a functional valve prototype for a customer embarking upon a mission to the moon in 2021.

A METHOD X 3D printer from desktop 3D printer provider and Stratasys subsidiary MakerBot was used to print the valve, reducing turnaround time from days to hours.

“We have a customer going to the moon in 2021 who commissioned us to build some valves for them,” said Luke Colby, president, and CEO of Triton Space Technologies. “We wanted to create a functional prototype of the valve, to check that all the parts fitted together properly and that the internal parts could slide and move as they should.

“We went into it not really expecting that the METHOD X would be able to keep the tolerances needed for the sliding parts to move, but it did.”

The METHOD X

MakerBot launched its METHOD X 3D printer in August 2019, less than 12 months after unveiling its predecessor, the METHOD. The main difference between the two printers is the METHOD X’s capability to support more challenging materials, such as METHOD X ABS. Designed to fill a niche in the market between desktop and industrial systems, METHOD X is engineered to provide a more industrial-grade machine to manufacturing professionals.

Earlier this year, 3D printing material provider Polymaker qualified three polycarbonate (PC) materials for MakerBot’s METHOD X, namely Polymaker PC-PBT, PolyMax PC-FR, and PolyLite PC, bringing the METHOD’s portfolio of materials to nine.

Having used large-scale industrial 3D printers in the past, Colby was intrigued to see whether a desktop machine could be used to produce truly functional prototypes.

“The METHOD X 3D printer has evolved as a tool, providing us with a high level of reliability during part production,” he said. “In our line of business, this is essential – especially in comparison to other 3D printers where there’s a risk that the final part will not come out as you’d expect. METHOD X mitigates risk by helping us to answer questions much earlier on in the design phase, so that’s very valuable.”

Bringing 3D printing in-house

Before turning to the METHOD X, Triton manufactured prototypes from sheet aluminum in its machine shop, a process which could take between two or three days to complete each prototype. This process also created a significant amount of material waste. Alternatively, Triton would outsource the work to a 3D printing service bureau, however this merely extended the time taken to produce the prototype, and didn’t always provide usable parts.

“We know what our design intent is, so when we print something, we know if the part is going to be useful,” Colby explained. “If we have to send it out to an external agency, the part might not necessarily be oriented in the right direction that’s not useful to us.”

This prompted Triton to bring the 3D printing of prototypes in-house, to give the team greater control and flexibility over the production process.

“Now, if a design doesn’t come out quite right, or we want to make a change, we can do that ourselves very quickly,” Colby continued. “The reliability of the METHOD X means we can set a part to print overnight knowing it will be ready to use in the morning. Using the app, we can check on the progress of the print remotely. That is a really practical feature.”

Supported by Stratasys

To produce functional prototypes that meet the tolerance requirements of the aerospace industry, Triton employs Stratasys’ SR-30 soluble support material. Producing the prototypes with soluble supports reduces the need for parts to be filed or sanded and maintains their utility. 3D printing also enables the production of more complex geometries with fewer individual parts.

The METHOD X enables Triton to print prototypes in durable engineering-grade ABS, and the firm is excited about the potential of MakerBot’s Nylon Carbon Fiber material.

“We also used the METHOD X to create a prototype of an injector head assembly for the manifold of a small rocket engine,” said Colby. “The idea was that it should have one common sliding surface that would open up with flow passages for both propellants at the same time. That would not have been possible with traditional manufacturing methods, as you end up with an assembly of many different parts coming together with a whole lot of seals in between them.”

“The modularity of the METHOD extruders will enable us to continually expand and improve what we are able to do with different materials. That’s really important to us, because most products become obsolete almost as soon as you buy them.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Triton used the METHOD X to produce valve prototypes for a 2021 lunar mission. Image via Triton Space Technologies.