The M3D Promega 3D printer is a new, large-format printer that launched this past June. Five months into its pre-order campaign, we’re happy with the response so far: over 660 printers sold, the equivalent to about 15% of the professional market (considering ~4,000 professional 3D printers are sold per quarter). In this article, we’ll look closer at features that illustrate why the Promega is going to shake up the ‘prosumer’ and professional 3D printing industries.

Build volume

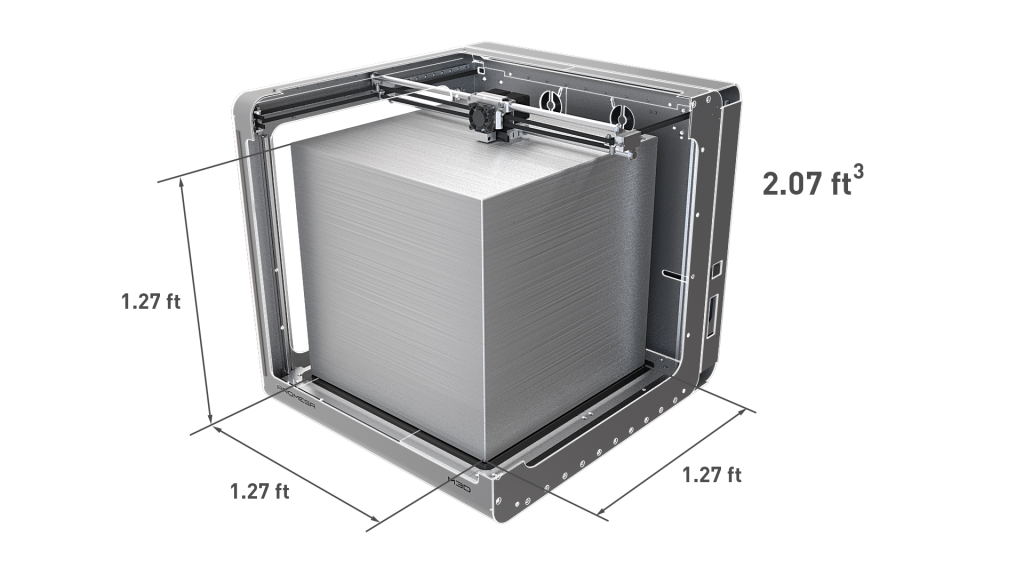

The first thing that stands out about the Promega is its size and space efficiency. The printer stands at 20”x20”x22” itself, and encloses a 15.3”-cubed build volume, making it one of the largest build volumes in its $2000-$4000 price tier. It’s also worth noting that the design enables over 40% of the Promega’s volume (close to 75% per dimension) as actual build volume, quite possibly making it the most space-efficient 3D printer in its class.

Extruder Subsystem with compound hot-ends

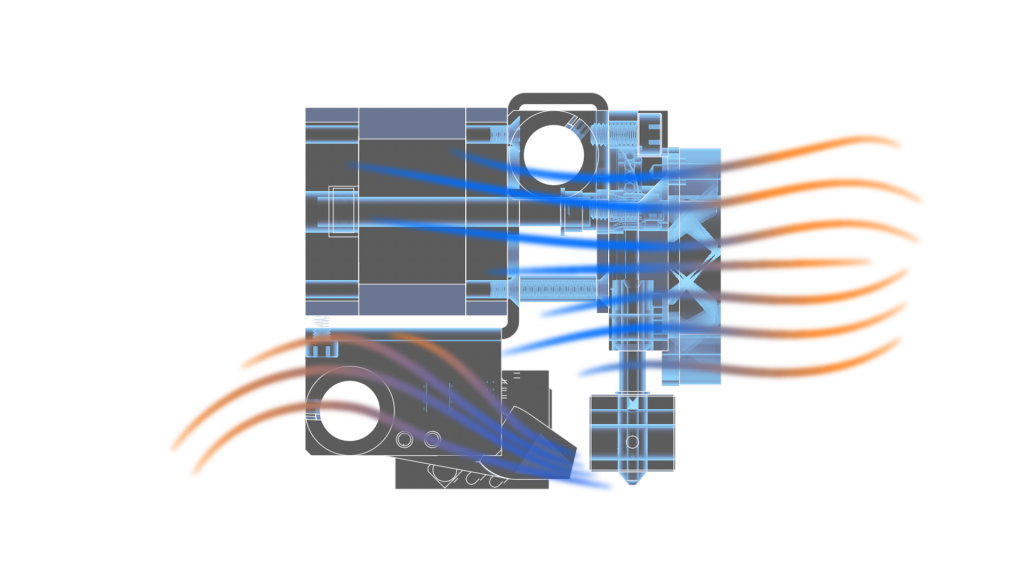

The Promega’s extruder sub-system consists of two Nema motors with 303 stainless steel direct-drive gears, and multiple slim profile blowers that we call a “Blade” fan system. This allows users to print in a variety of hardware setups and software settings with consistent, quality results.

Additionally, we are offering our own hot-end solutions, called K’tana and Compound. Both use 303 stainless steel, are seamless from where filament enters to its exit (so they’re leak-proof) and can be used without having to re-calibrate the height after nozzle changes. The K’tana is a multi-color, dual-nozzle hot-end and the Compound is a single mixing-nozzle hot-end that allows co-extrusion of various printing filament and separate support material, dual-color mixing, or multi-material mixing.

Promega backers can select either hot-ends, or upgrade to have both. These new hot-ends are open-source compatible, to allow printing with normal open-source hot-ends, or our new solutions.

Z Platform

Another interesting feature of M3D’s Promega is its Z-Platform. Designed to look like a ‘floating bed’, it rides along rails as concealed belts move the system, reducing wobble compared to leadscrew-driven designs.

CoreXY Gantry System

The extruder is driven by a CoreXY motion system, granting better agility (faster cornering), accuracy (elimination of torsional stress and backlash) and print quality (reduced surface moiring). It is also responsible for the Promega’s fast print speeds (up to 300mm/s for motion and typical printing between 40-80mm/s) and allows the Promega to maintain direct-drive extrusion on the printhead and printing in flexible materials, rather than using a Bowden feed. Further, the Gantry motors and belt tensioning mechanisms are easily accessible for ease of maintenance and tuning.

Heated Bed

Our approach to the heated bed is truly novel. Called an ‘Ecoheat’ heated bed using Flareline technology, the bed uses a grid of heated ‘flarelines’ run throughout an insulated bed which heat it locally, similar to how a car’s rear windshield defrost system works. The lines heat up quickly and maintain temperature with much less energy than traditional systems, while still providing consistent, superior heating across the bed.

Our heated bed reduces energy costs from 66-83%. To maximize the savings, users can select a single-zone option, heating just the center of the bed for smaller prints. The design is patent pending, making it maybe the only part of the printer that is not completely open source.

Heated Chamber

While the bed has been engineered to retain much of the heat, a heated chamber is realized from the combined effects of the bed and space-efficient enclosed frame. A programmable exhaust fan allows for a controlled heated build chamber up to about 60°C. This will help prevent warping, critical for large prints, where thermal contraction effects are amplified.

Duet 2 Maestro

Last but not least: electronics. The open-source nature of the Promega gives users flexibility and control in the way they operate and maintain this 3D printer, with respect to software, hardware and firmware. This also allows customers to customize and expand as desired.

A big update we recently announced is a partnership to create a Duet3D board, specifically for M3D’s Promega. We are finalizing an agreement with Duet3D developers but the board should have the native ability to manage a mixing extruder, ethernet and USB connections, Trinamic motor drivers to give super-quiet operation, with 1/256 microstepping, among other features.

The Promega is currently at $1,810 and will eventually hit $3,500 at the end of the campaign. So far, the project has brought in upwards of $800,000, already making it one of the top-grossing pre-order campaigns for a 3D printer this year. We are so excited about the Promega’s reception and and thankful to our Backers who are making it a serious mover in the Professional category already. More information on the Promega can be found on our site and the FitForLaunch project page.