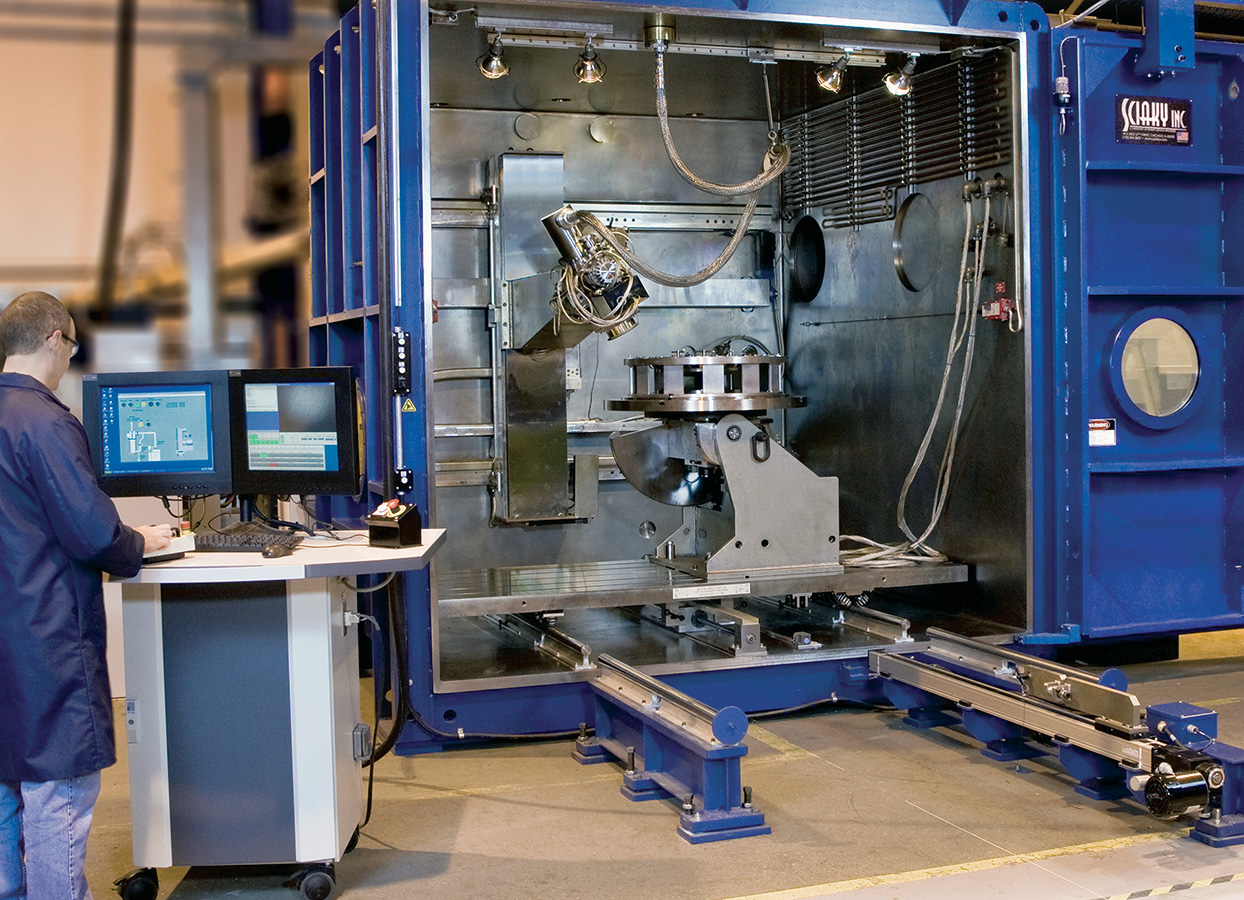

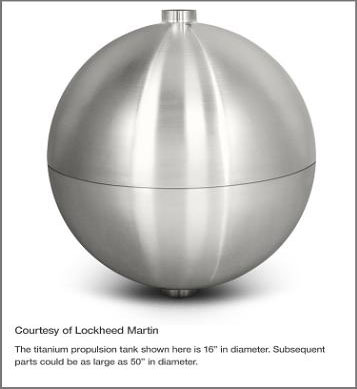

Sciaky Inc recently made headlines when the company announced that its large-scale EBAM system would be available for purchase, and again when it announced its first sale barely a month later. The company has now announced that its second customer is Lockheed Martin, one of the largest aerospace companies in the world and one of the key players in the technology’s development.

“Sciaky is proud to partner with a progressive leader like Lockheed Martin Space Systems” said Sciaky general manager Mike Riesen. “Sciaky’s EBAM technology will help Lockheed Martin significantly reduce material costs, lead times, and machining times.”

Here’s a promotional video about the technology from Sciacky:

EBAM – Electron Beam Additive Manufacturing – technology uses a high-powered electron beam to deposit metal directly on the build platform with the help of a CAD program. Once the rough part is created, it is processed and cleaned, resulting in a strong, fully-dense and void free metal part. The process reduces the steps involved in traditional manufacturing techniques typically used to create large-scale parts. The massive 110inch x 110inch x 110inch (279cm x 279cm x 279cm) is optimised to help develop components for jet engines, airframes, landing gear, missiles and automotive parts.